A kind of aluminum clad aluminum alloy wire and preparation method thereof

A kind of aluminum alloy wire, aluminum alloy technology, applied in the direction of metal/alloy conductor, cable/conductor manufacturing, electrical components, etc., can solve the problem of affecting the interface performance, and achieve the effect of reducing line loss, improving strength and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

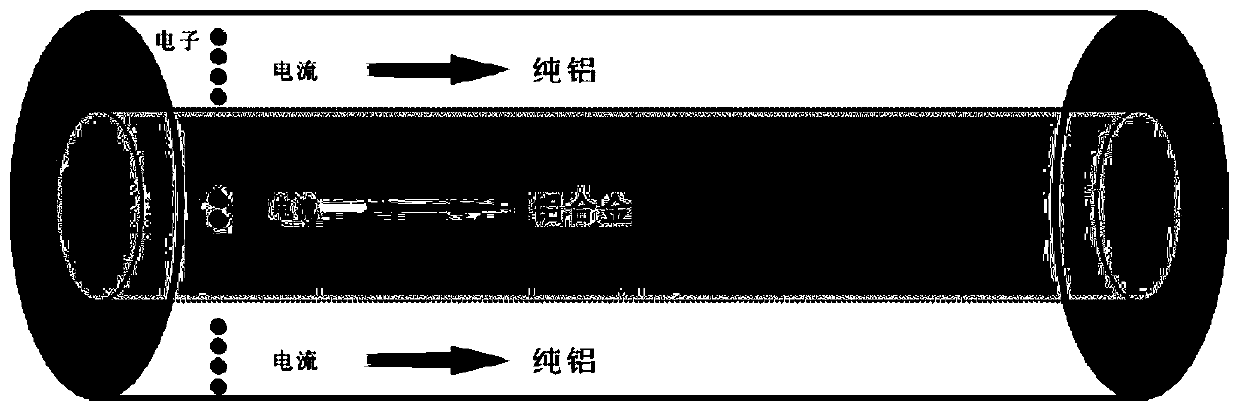

[0042] In this embodiment, an aluminum-clad aluminum alloy wire is prepared, the outer layer is A6 industrial pure aluminum, and the core material is an aluminum-magnesium-silicon alloy wire; wherein: the industrial pure aluminum composition is (wt.%): Si 0.03%, Fe 0.10%, Mg 0.01%, Cu 0.01%, aluminum balance. The composition of the aluminum alloy is (wt.%): Si 0.57%, Fe 0.15%, Mg 0.72%, La-Ce mixed rare earth 0.15%, Ti 0.12%, Cu 0.01%, and the balance of aluminum.

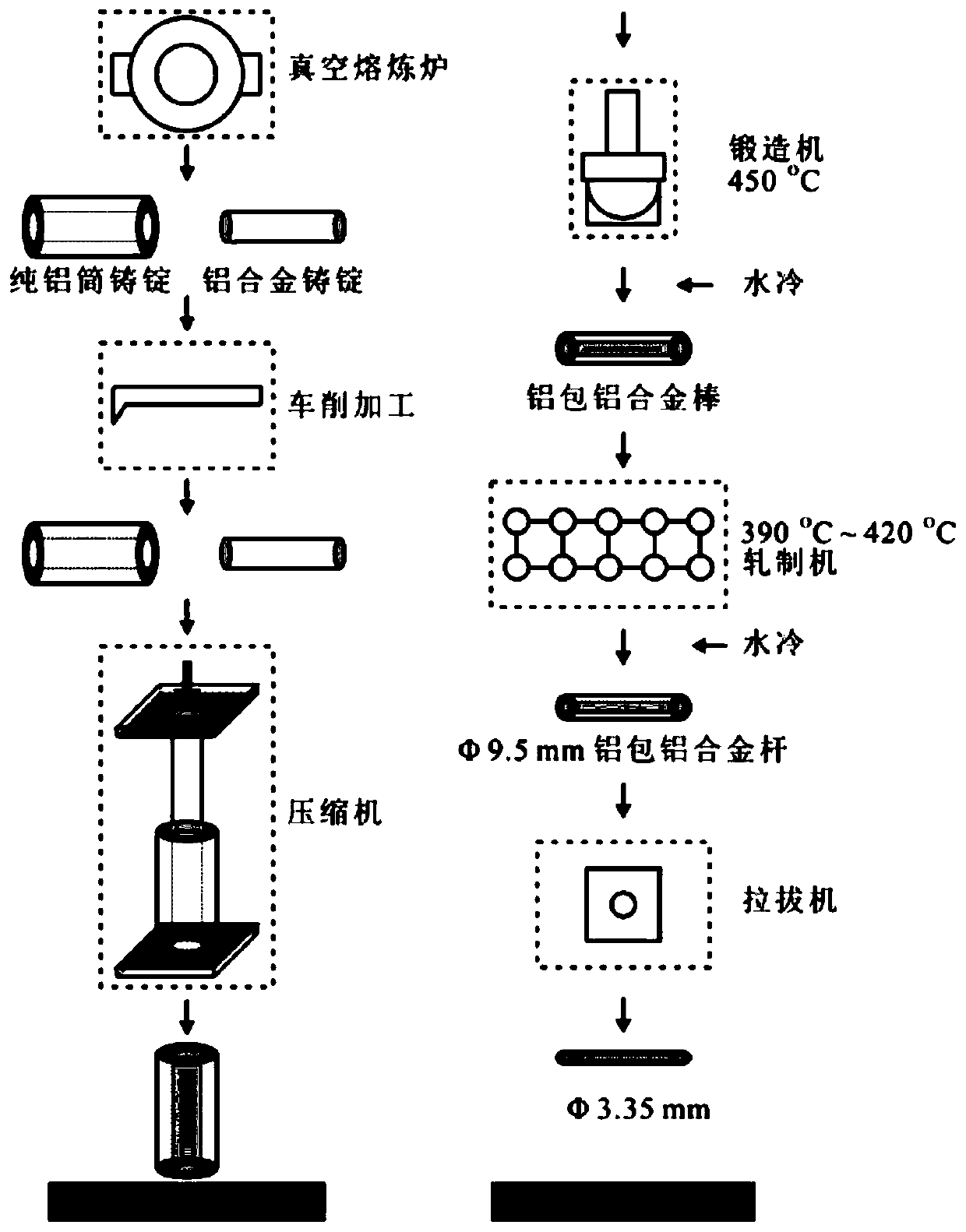

[0043] The preparation process of the aluminum clad aluminum alloy wire in this embodiment is as follows:

[0044] Step 1: Prepare A6 industrial pure aluminum cylindrical ingot and aluminum magnesium silicon alloy cylindrical ingot by vacuum smelting.

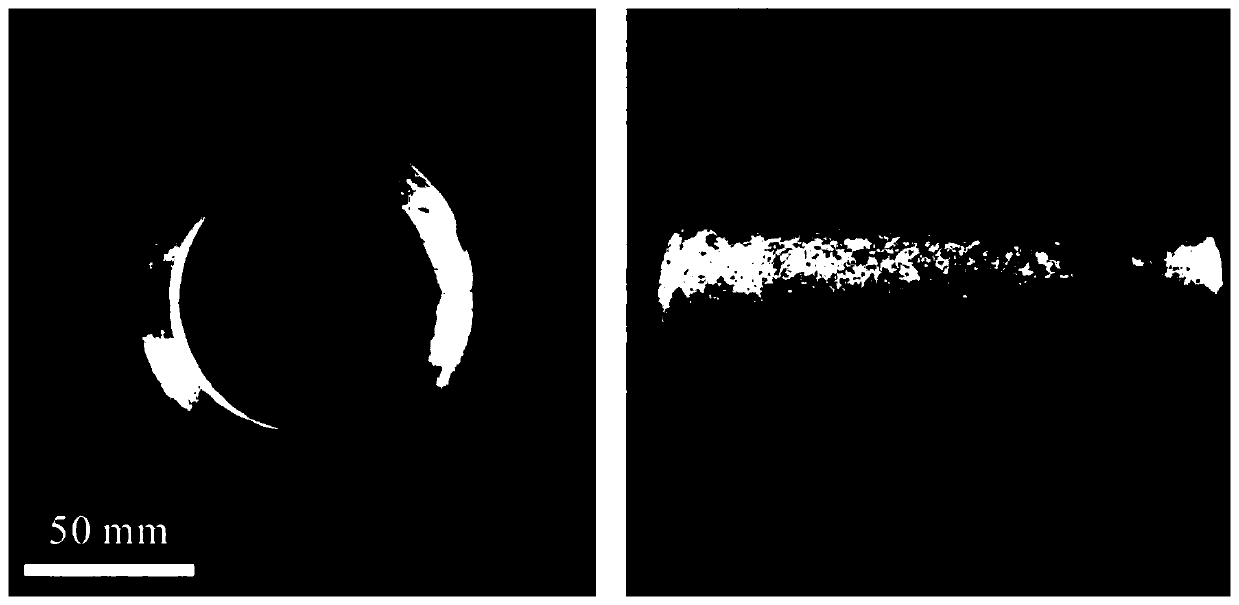

[0045] Step 2: Obtain a hollow pure aluminum cylinder with an inner diameter of 50.0mm ( image 3 ) and a solid aluminum alloy cylinder with a diameter of 50.5mm.

[0046] Step 3: Clean the inner wall of the hollow pure aluminum cylinder and the outer surface of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com