Filter unit capable of lowering air flow temperature and supplementing beneficial components

A filter unit, a beneficial technology, applied in the direction of e-liquid filter elements, applications, tobacco, etc., can solve the problems of reducing filter sticks, poor acceptance, and less release of beneficial components, and achieve the effect of enhancing usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Filter units are obtained by:

[0030] The first step: take continuous sheets of cellulose paper and polylactic acid film, the thicknesses are 30 μm and 20 μm respectively, and the width is 500 mm; take composite glue, polyethylene glycol 4000, nicotine, and mixed spices containing tobacco extract; appropriate amount .

[0031] Step 2: Dissolve polyethylene glycol 4000, nicotine and mixed spices in water as usual, dissolve and mix evenly to obtain a mixed solution. The mixed solution was applied to a continuous sheet of cellulose paper in a coating manner, and unnecessary moisture was removed.

[0032] The third step: the continuous sheet of cellulose paper obtained in the second step is bonded to the continuous sheet of polylactic acid film through composite glue to obtain a composite sheet formed by bonding the polymer film and the cellulose paper.

[0033] The fourth step: cutting the composite sheet obtained in the third step to a width of 230 mm.

[0034] It was...

Embodiment 2

[0044] Filter units are obtained by:

[0045] Step 1: Take continuous sheets of cellulose paper and polylactic acid film, the thicknesses are 80 μm and 60 μm respectively, and the width is 330 mm; take composite glue, polyethylene glycol 4000; appropriate amount.

[0046] Step 2: Dissolve polyethylene glycol 4000 in water as usual, dissolve and mix evenly to obtain a mixed solution. The mixed liquor is applied to a continuous sheet of cellulose paper in a coating manner, and unnecessary moisture is removed.

[0047] The third step: the continuous sheet of cellulose paper obtained in the second step is bonded to the continuous sheet of polylactic acid film through composite glue to obtain a composite sheet formed by bonding polymer film and cellulose paper.

[0048] The fourth step: cutting the composite sheet obtained in the third step to a width of 150mm.

[0049] It was determined that the thickness of the obtained composite sheet was 140 μm, and the amount of polyethylene...

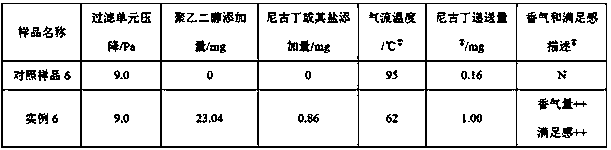

Embodiment 3

[0058] Filter units are obtained by:

[0059] The first step: take continuous sheets of cellulose paper and polypropylene film, the thicknesses are 120 μm and 20 μm respectively, and the width is 350 mm; take composite glue, polyethylene glycol 6000, nicotine, and mixed spices containing coffee extract; appropriate amount .

[0060] Step 2: Dissolve polyethylene glycol 6000, nicotine and mixed spices in water according to conventional proportions, dissolve and mix evenly to obtain a mixed solution. The mixed solution was applied to a continuous sheet of cellulose paper in a coating manner, and unnecessary moisture was removed.

[0061] The third step: the continuous sheet of cellulose paper obtained in the second step is bonded to the continuous sheet of polypropylene film through composite glue to obtain a composite sheet formed by bonding polymer film and cellulose paper.

[0062] The fourth step: cutting the composite sheet obtained in the third step to a width of 160 mm....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com