Numerically-controlled lathe

A technology for a CNC lathe and a bed, which is applied in the field of CNC lathes, can solve the problems of increased tailstock volume and weight, low work efficiency, and reduced reliability, and achieves the effects of simple structure, reduced labor costs, and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

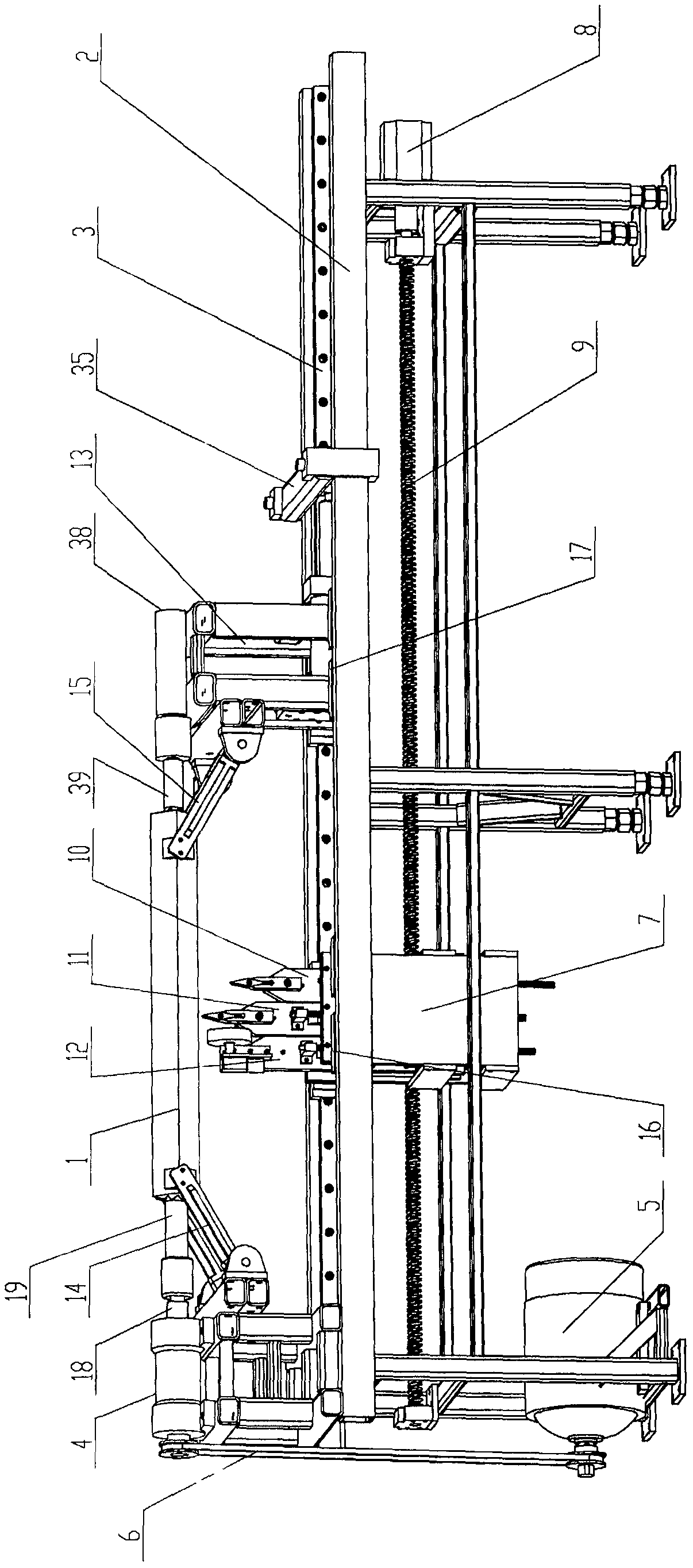

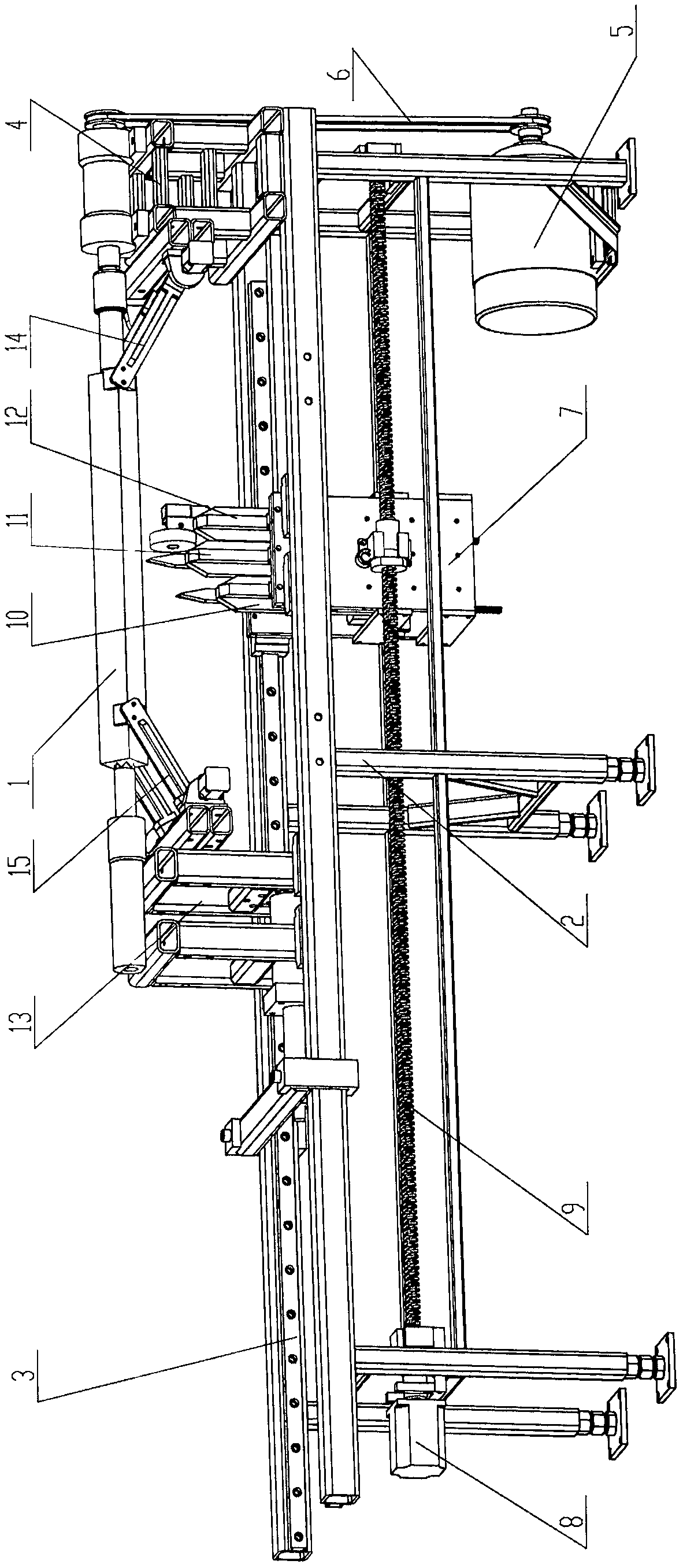

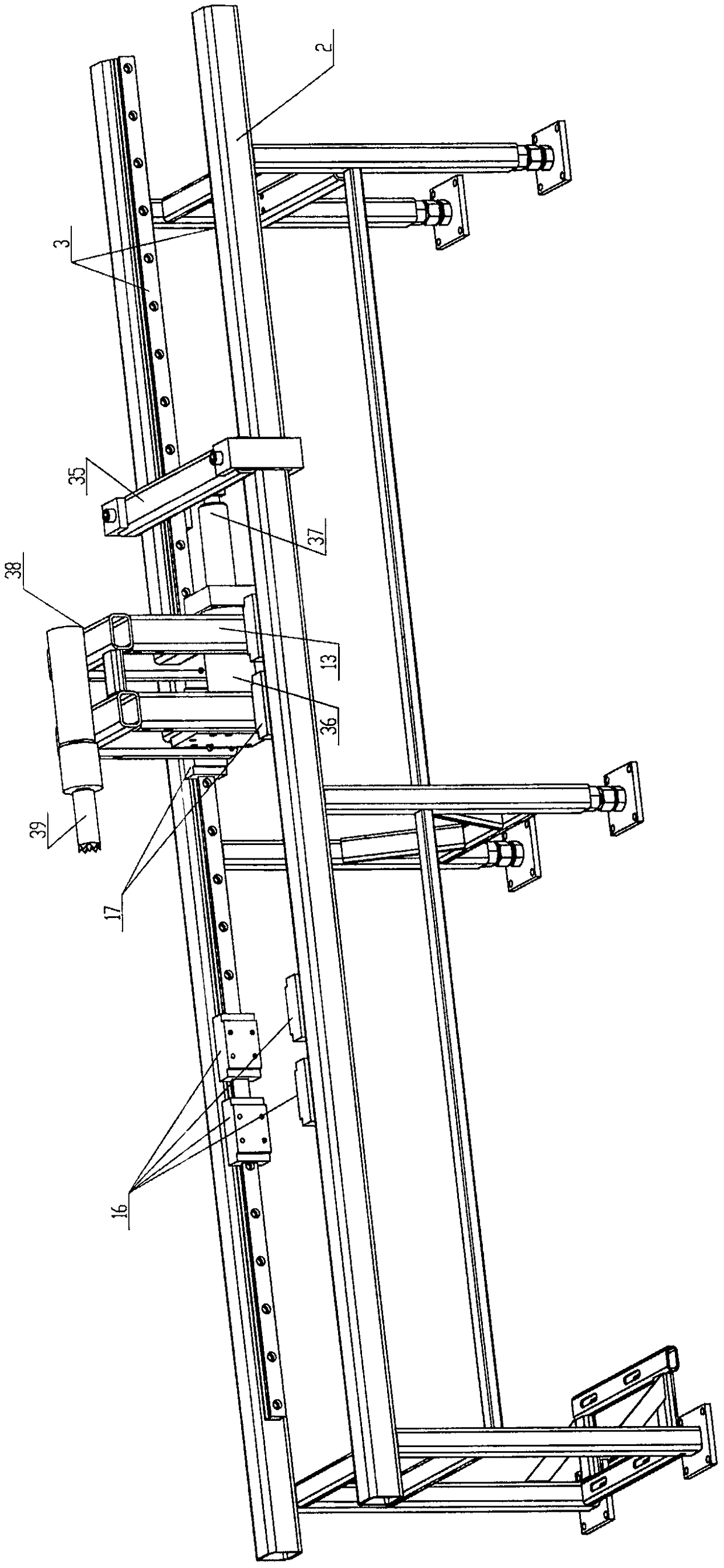

[0038] like figure 1 , 2As shown, the CNC lathe includes a bed 2, a bed guide rail 3, an axial clamping device composed of a main shaft fixed end 4 and a tail shaft moving end, and the main shaft end radially clamps the feeding device 14 and the tail shaft end The radial clamping and feeding device composed of the radial clamping and feeding device 15 is composed of the slide plate frame device 7 and three processing tool groups, and the slide plate frame drive screw rod 9 and the slide plate frame motor 8 Composed of the slide frame driving device. Wherein the fixed end 4 of the main shaft includes a main shaft 18 , a main shaft plum blossom thimble 19 , a pulley and a transmission belt 6 , and a main shaft motor 5 . The moving end of the tail shaft consists of a tail shaft fixing assembly including a tail shaft fixing bracket 35, a tail shaft moving assembly 38 including a tail shaft bracket 13, a tail shaft rotating plum blossom thimble 39, and a cylinder block 36, a cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com