Halogen-free flame-retardant TPO elastomer material and preparation method thereof

A technology of elastomer materials and raw materials, applied in the field of halogen-free flame-retardant TPO elastomer materials and its preparation, can solve problems such as limiting the use range of TPO, achieve significant economic benefits, improve processability, and facilitate processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

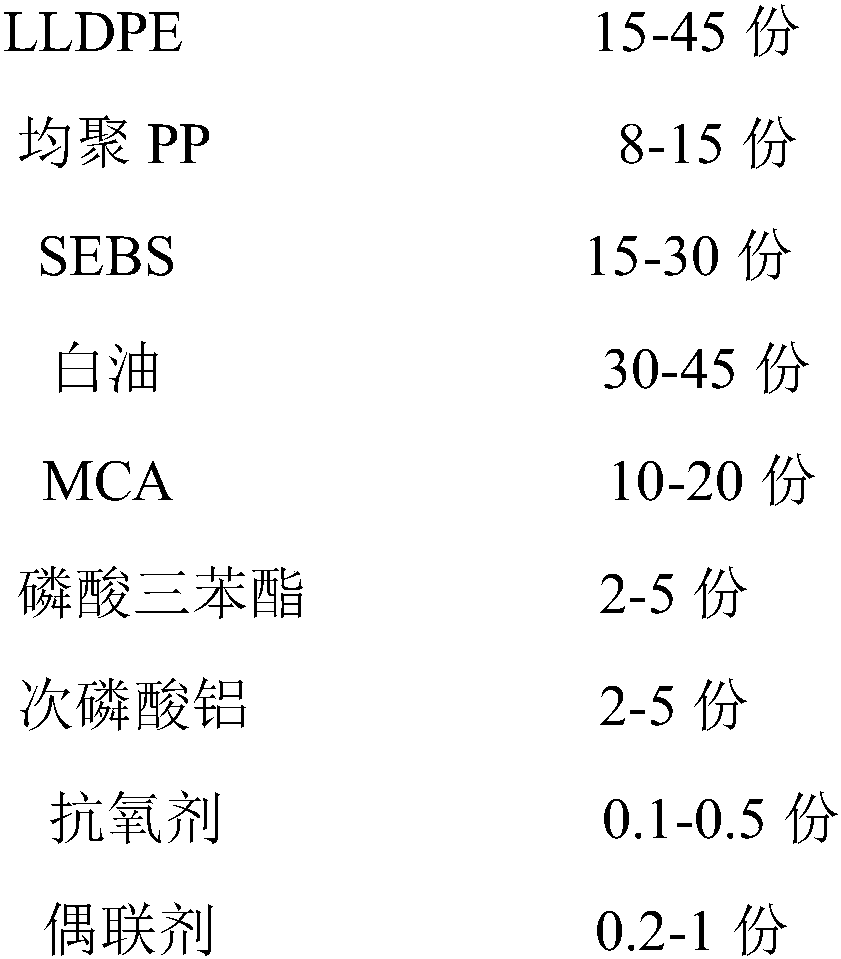

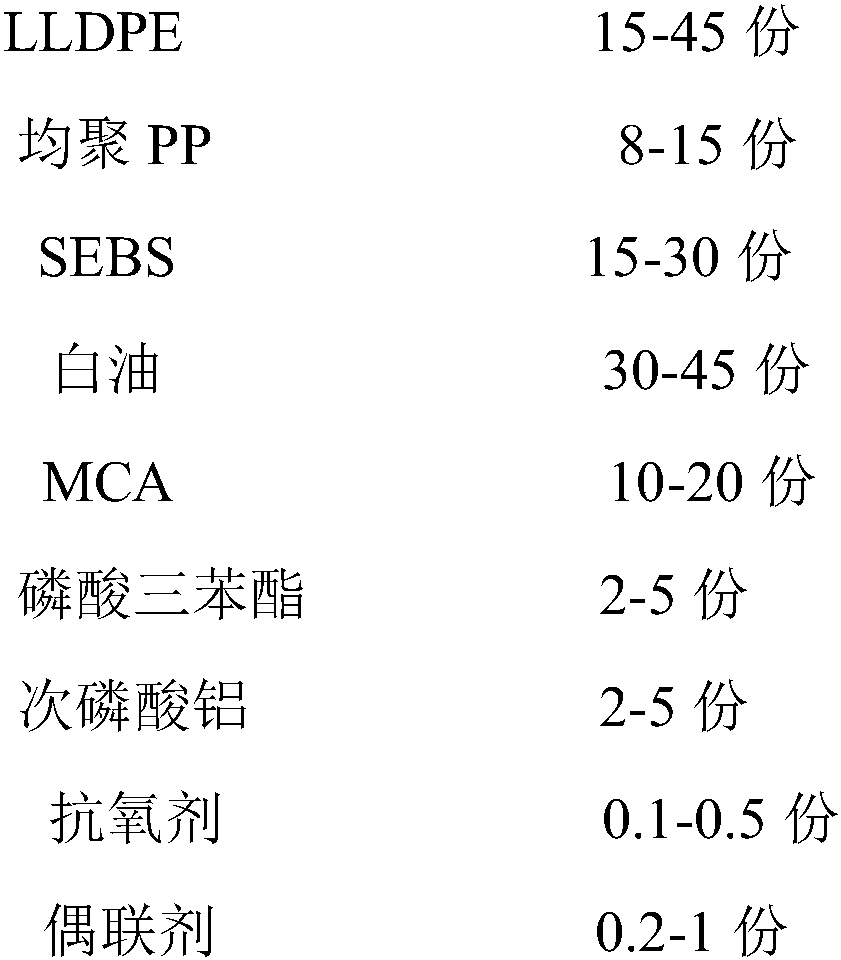

Method used

Image

Examples

preparation example Construction

[0038] The present invention also discloses a preparation method of the above-mentioned halogen-free flame-retardant TPO elastomer material, comprising the following steps:

[0039] (1) Take the parts by weight of the above-mentioned raw materials respectively, and set them aside for use; first divide the white oil into several equal parts, and add them to the SEBS in portions, after adding the white oil each time, Mix evenly in a high-mixer; after all the white oil is added, let stand to obtain a mixture;

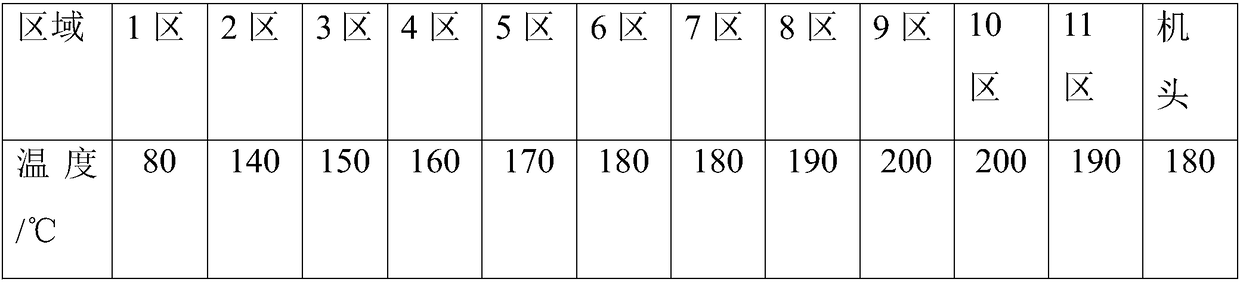

[0040] (2) In the mixture, add the described LLDPE, the described homopolymer PP, the described MCA, the described triphenyl phosphate, the described aluminum hypophosphite, the described antioxidant and The coupling agent is mixed in a high-speed mixer; then extruded and granulated by a twin-screw extruder to obtain the halogen-free flame-retardant TPO elastomer material.

Embodiment 1

[0050] (1) Take by weighing 20 parts of SEBS and 30 parts of paraffin-based white oil, then divide the weighed white oil into three equal parts and add in SEBS gradually, add the mixture of SEBS and white oil at high temperature after each addition of white oil Mix in the mixer for 5 minutes, and finally let the mixed mixture stand for 24 hours;

[0051] (2) Weigh 35 parts of LLDPE with a melt index of 5g / 10min, 15 parts of homopolymerized PP with a melt index of 10g / 10min, 15 parts of MCA, 4 parts of triphenyl phosphate, 4 parts of aluminum hypophosphite, and 0.3 parts of antioxidant agent (the composite system of antioxidant 1010 and antioxidant 168, the mass ratio is 2: 1), 0.5 parts of KH550, mix it with the SEBS mixture in step (1) in a high mixer for 5 minutes;

[0052] (3) Extrude and granulate the mixture in step (2) with a twin-screw extruder to obtain a halogen-free flame-retardant TPO elastomer.

Embodiment 2

[0054] (1) take by weighing 15 parts of SEBS and 30 parts of naphthenic white oils, then divide the weighed white oils into three equal parts and add in SEBS gradually, add the mixture of SEBS and white oils at every turn after adding white oils Mix in a high mixer for 5 minutes, and finally let the mixed mixture stand for 24 hours;

[0055] (2) Weigh 35 parts of LLDPE with a melt index of 2g / 10min, 15 parts of homopolymerized PP with a melt index of 5g / 10min, 10 parts of MCA, 2 parts of triphenyl phosphate, 2 parts of aluminum hypophosphite, 0.1 part of antioxidant agent (the composite system of antioxidant 1010 and antioxidant 168, the mass ratio is 2:1), 0.2 parts of KH560, mix it with the SEBS mixture in step (1) in a high mixer for 5 minutes;

[0056] (3) Extrude and granulate the mixture in step (2) with a twin-screw extruder to obtain a halogen-free flame-retardant TPO elastomer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com