Fuel cell prepared based on methanol and water renormalization

A fuel cell, high temperature fuel cell technology, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve problems such as hindering the progress and development of hydrogen fuel cells, uneven fluid distribution, and low methanol conversion rate, etc. Achieve high energy conversion efficiency, improve hydrogen production efficiency, and high hydrogen production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

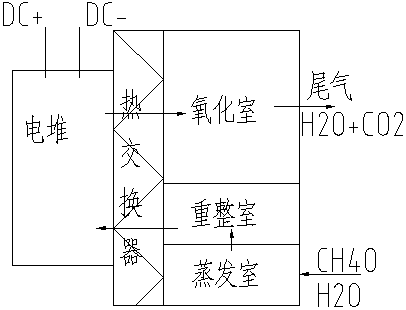

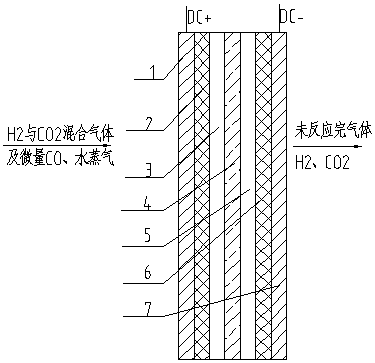

[0030] Such as figure 1 As shown, a fuel cell prepared based on reforming methanol and water includes an evaporation chamber, and an evaporator is arranged in the evaporation chamber, and the evaporation chamber is connected with the reforming chamber, and the reforming chamber is connected to the high temperature through the microchannel of the electrode plate. The fuel cell stacks are connected, the high-temperature fuel cell stack is provided with an anode and a cathode, a proton membrane is provided between the anode and the cathode, and a catalyst is provided at the anode;

[0031] The catalysts include copper-zinc catalysts for methanol reforming, platinum catalysts for high-temperature fuel stacks, and platinum-rhodium-palladium three-way catalysts for oxidation in oxidation chambers.

[0032] The ratio of methanol and water is 3:2 by volume.

[0033] The evaporation chamber evaporates a mixture of methanol and water in a certain ratio, and then the vapor of methanol a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com