Noodles and production method thereof

A production method and noodle technology, applied in food science, food preservation, application, etc., can solve the problems of adding food additives, color deterioration, poor taste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

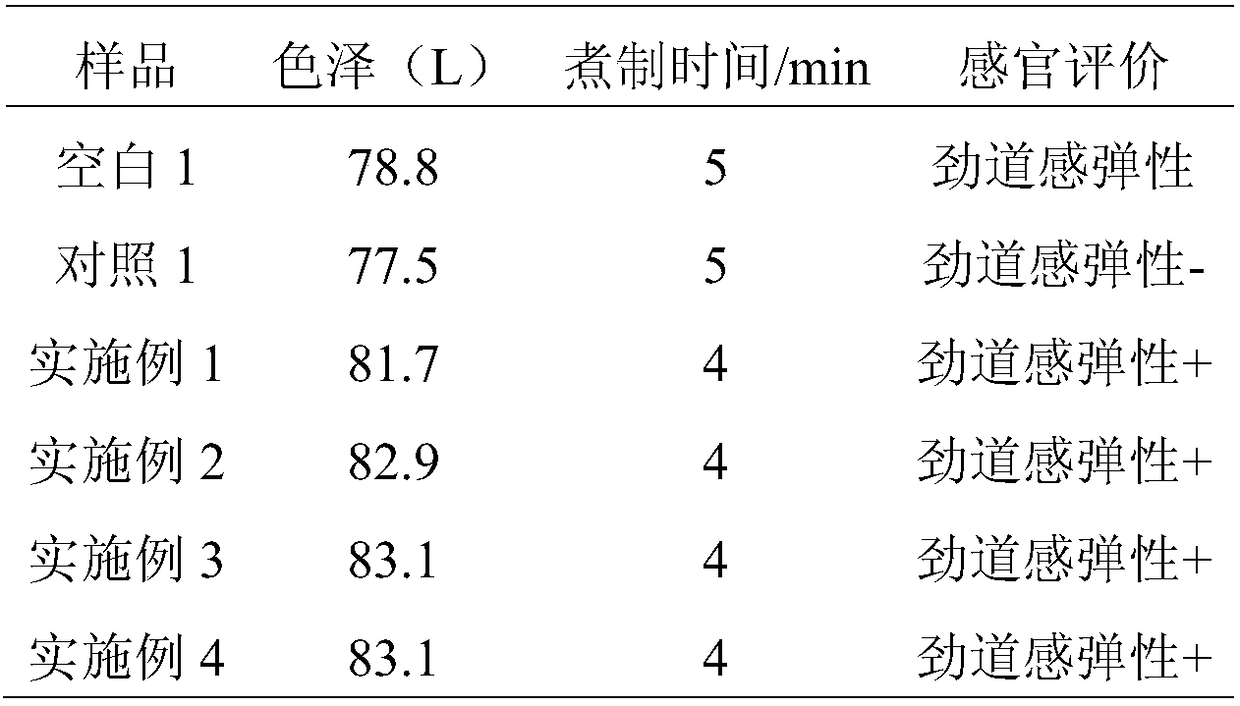

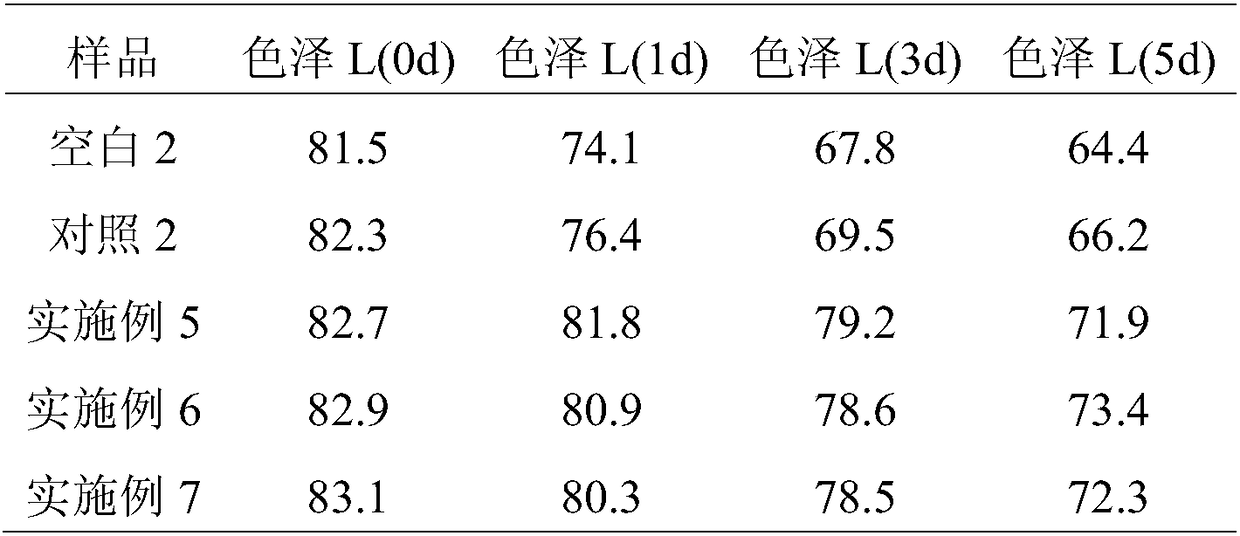

Examples

Embodiment 1

[0102] Weigh 100kg of flour, 0.2kg of yeast, and 31kg of water. First, dissolve the yeast in water at 40°C, activate it for 10 minutes, then mix the bacterial liquid with 10kg of flour, and ferment at 40°C for 1.5 hours; then fully mix the fermented dough with the remaining 90kg of flour, and knead the dough for 10 minutes; let stand After 10 minutes, press into sheets and cut into strips to make raw noodles; place the raw noodles in a drying room for secondary fermentation, and dry them to obtain finished dried noodles.

[0103] The secondary fermentation conditions are as follows: a temperature of 35°C, a humidity of 80%, and a time of 1 hour.

[0104]Drying conditions are: main drying section, temperature 36°C, humidity 75%, time 30min; equilibrium drying section: temperature 42°C, humidity 70%, time 160min; cooling slow crisp section: temperature 28°C, humidity 55%, time 40min.

Embodiment 2

[0106] Weigh 100kg of flour, 0.1kg of yeast, 0.2kg of lactic acid bacteria, and 31kg of water. First, dissolve the yeast and lactic acid bacteria in water at 40°C, activate for 10 minutes, then mix the bacterial liquid with 10kg of flour, and ferment at 40°C for 1.5h; then fully mix the fermented dough with the remaining 90kg of flour, and knead for 10 minutes; After standing still for 10 minutes, the raw noodles are made by pressing into sheets and cut into strips; the raw noodles are placed in a drying room for secondary fermentation, and the finished dried noodles are obtained after drying.

[0107] The secondary fermentation conditions are as follows: a temperature of 35°C, a humidity of 80%, and a time of 1 hour.

[0108] Drying conditions are: main drying section, temperature 36°C, humidity 75%, time 30min; equilibrium drying section: temperature 42°C, humidity 70%, time 160min; cooling slow crisp section: temperature 28°C, humidity 55%, time 40min.

Embodiment 3

[0110] Weigh 100kg of flour, 0.3kg of yeast, 0.1kg of lactic acid bacteria, and 31kg of water. First, dissolve the yeast and lactic acid bacteria in water at 40°C, activate for 10 minutes, then mix the bacterial liquid with 20kg of flour, and ferment at 40°C for 0.5h; then fully mix the fermented batter with the remaining 80kg of flour, and knead for 10 minutes; After standing still for 10 minutes, the raw noodles are made by pressing into sheets and cut into strips; the raw noodles are placed in a drying room for secondary fermentation, and the finished dried noodles are obtained after drying.

[0111] The secondary fermentation conditions are as follows: a temperature of 35°C, a humidity of 80%, and a time of 1 hour.

[0112] Drying conditions are: main drying section, temperature 36°C, humidity 75%, time 30min; equilibrium drying section: temperature 42°C, humidity 70%, time 160min; cooling slow crisp section: temperature 28°C, humidity 55%, time 40min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com