From-top-to-bottom liquid metal 3D printing forming equipment

A liquid metal, 3D printing technology, applied in the direction of additive processing, can solve problems such as high cost, achieve the effect of long service life, improved mechanical properties, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

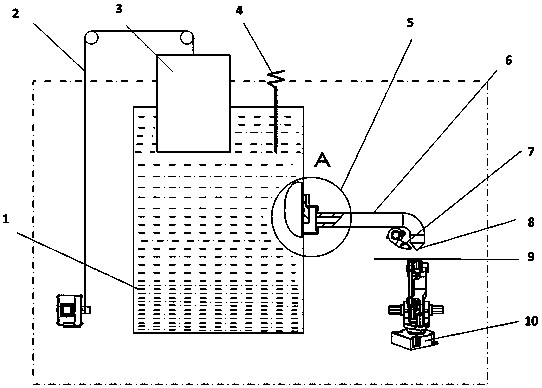

[0022] A top-down liquid metal 3D printing and forming equipment. According to the printing path controlled by the layered data of the product's 3D model, the manipulator controls the product forming platform to complete the three-dimensional movement of the X, Y, and Z axes under the drive of the printing software and the control system. Realize the 3D production of metal parts, and can produce small and medium-sized metal parts with arbitrary three-dimensional shapes.

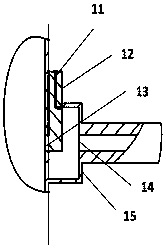

[0023] The present invention is a liquid metal 3D forming equipment. The structure mainly includes a melting furnace 1, a pulley block 2, a high temperature resistant rod 3, a high temperature liquid level probe 4, a regulating valve 5, a liquid metal conduit 6, a cooling gas nozzle 7, a nozzle 8, and a molding machine. Platform 9 and manipulator 10; high temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com