Mobile Facade Hard Rock Grooving Machine and Its Construction Technology

A grooving machine and vertical facade technology, which is applied in the direction of stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of increasing the amount of concrete poured on ribbed walls and ribbed columns, large crushing vibration, and excessive consumption. Achieve the effects of reducing the amount of muck transported abroad and subsequent concrete pouring, shortening the preparation time, and avoiding safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1 is a mobile facade hard rock grooving machine without a safety limiting device

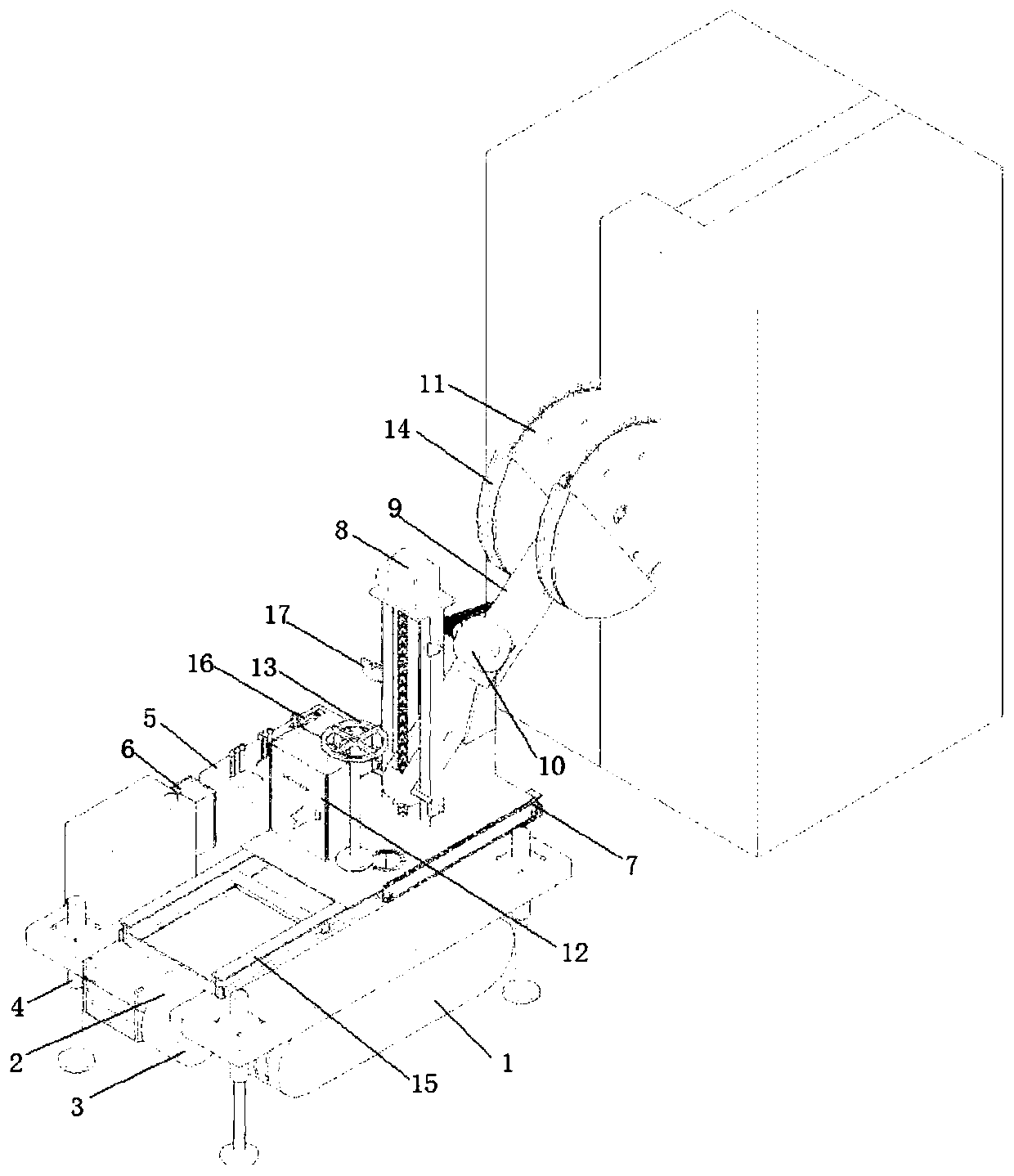

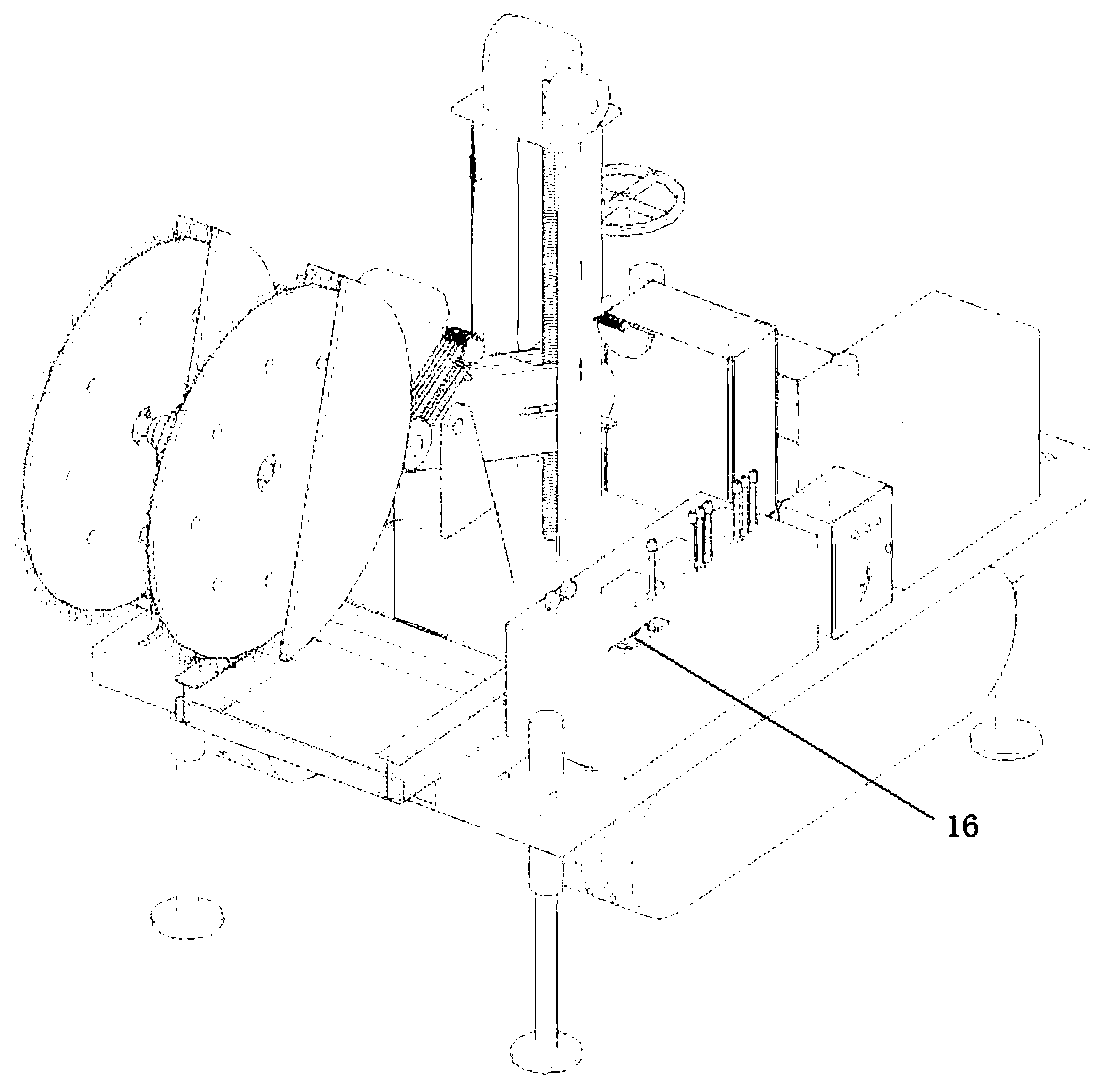

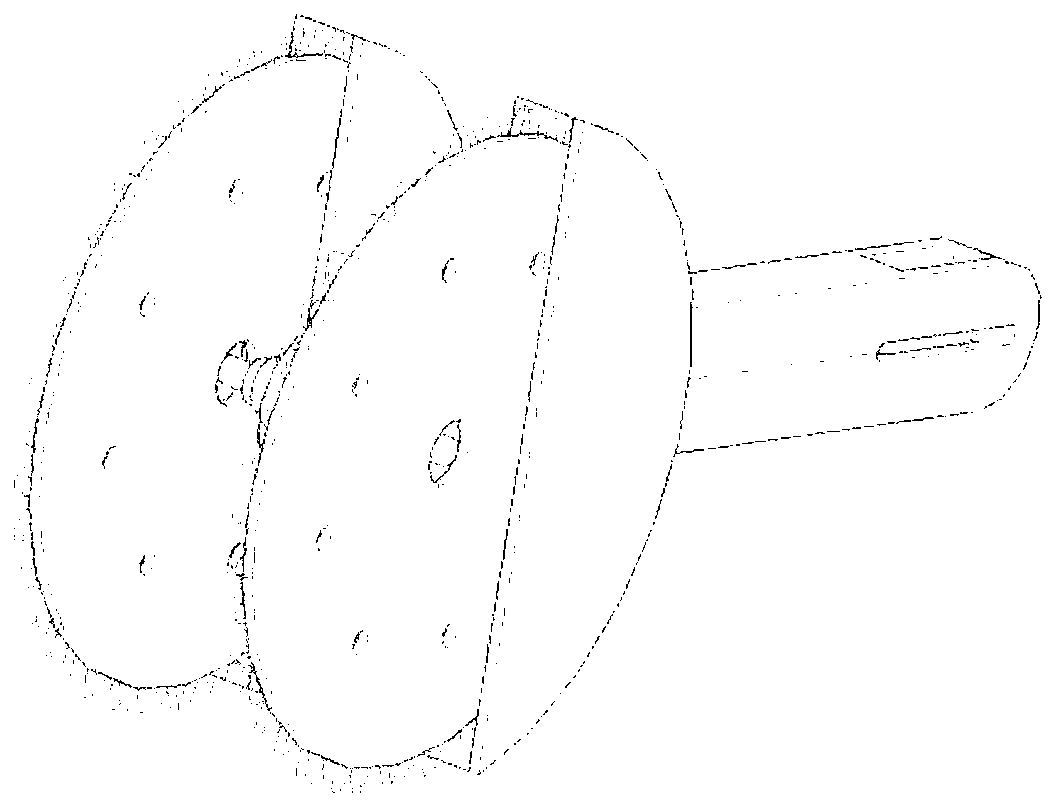

[0047] like Figure 1-3 As shown, the mobile façade hard rock grooving machine includes a crawler mechanism 1 that provides the movement of the grooving machine, a working platform 2 that provides the staff to stand while operating, and an electric hydraulic pump 3 that controls the circulation of hydraulic oil to support the grooving The leveling outrigger oil cylinder 4 that ensures the overall levelness of the grooving machine and the verticality of the cutting piece is used to operate the crawler traveling mechanism 1 and adjust the operating mechanism 5, and the traveling electric control cabinet 6 that supplies power to the traveling and adjusting operating mechanism 5 , the cutting machine moving rail frame 7 for installing the cutting saw blade, the cutting blade up and down moving mechanism 8 for adjusting the up and down displacement of the cutting saw blade, and the adjus...

Embodiment 2

[0053] Embodiment 2 is a mobile facade hard rock grooving machine that is not equipped with a liquid level measuring instrument and a verticality visual observer

[0054] Mobile facade hard rock grooving machine, including the crawler walking mechanism 1 that provides the movement of the grooving machine, the working platform 2 that provides the staff to stand when operating, and the electric hydraulic pump 3 that controls the circulation of hydraulic oil, used to support the grooving machine to ensure cutting Outrigger oil cylinder 4 for leveling the overall levelness of the slot machine and the verticality of the cutting piece, used to operate the walking and adjusting the operating mechanism 5 of the crawler traveling mechanism 1, and the traveling electric control cabinet 6 for power supply to the traveling and adjusting operating mechanism 5, for installing and cutting The cutting machine moving rail frame 7 of the saw blade, the cutting blade up and down moving mechanism ...

Embodiment 3

[0060] Embodiment 3 is a mobile facade hard rock grooving machine equipped with a liquid level measuring instrument, a verticality visual observer and a safety limit device

[0061] Mobile facade hard rock grooving machine, including the crawler walking mechanism 1 that provides the movement of the grooving machine, the working platform 2 that provides the staff to stand when operating, and the electric hydraulic pump 3 that controls the circulation of hydraulic oil, used to support the grooving machine to ensure cutting Outrigger oil cylinder 4 for leveling the overall levelness of the slot machine and the verticality of the cutting piece, used to operate the walking and adjusting the operating mechanism 5 of the crawler traveling mechanism 1, and the traveling electric control cabinet 6 for power supply to the traveling and adjusting operating mechanism 5, for installing and cutting The cutting machine moving rail frame 7 of the saw blade, the cutting blade up and down moving...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com