Device and method for preparing continuous fiber reinforced thermoplastic prepreg tape

A technology of reinforced thermoplastic and continuous fiber, applied in the direction of coating, etc., can solve the problems of unstable resin content of prepreg tape, impurity cannot be completely removed, and difficult to adjust in real time, so as to achieve stable and controllable resin content, shorten resin flow process, The effect of less fiber damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

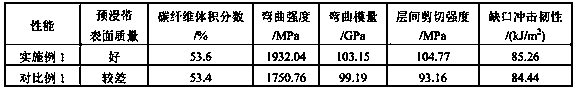

[0051] The equipment and method of the present invention are used to prepare continuous carbon fiber reinforced thermoplastic polyetheretherketone composite material prepreg tape, and the mechanical properties of the unidirectional laminate are investigated. The raw materials used are as follows:

[0052] Continuous carbon fiber (Toray T700SC, 12K continuous carbon fiber);

[0053] Polyetheretherketone (PEEK) resin powder (Victrex 450PF, melting point 343°C, powder particle size 50μm).

[0054] The preparation steps of the continuous carbon fiber reinforced thermoplastic polyether ether ketone composite prepreg tape are as follows:

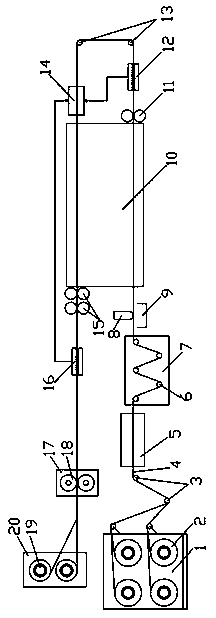

[0055] A roll of 12K T700 carbon fiber is placed on the spindle of the creel 1, and guided by the guide roller 3, the carbon fiber enters the spreading device 2. In this embodiment, a mechanical spreading rod is used to spread the carbon fiber to make it thin. After the carbon fiber is spread, it enters the impregnation tank 7 filled with PEEK r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Powder particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Powder particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com