A method for forming a square, equal-section, and large-size composite material box

A composite material and molding method technology, which is applied in the field of composite material box molding to achieve the effects of low porosity, good box surface quality and controllable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

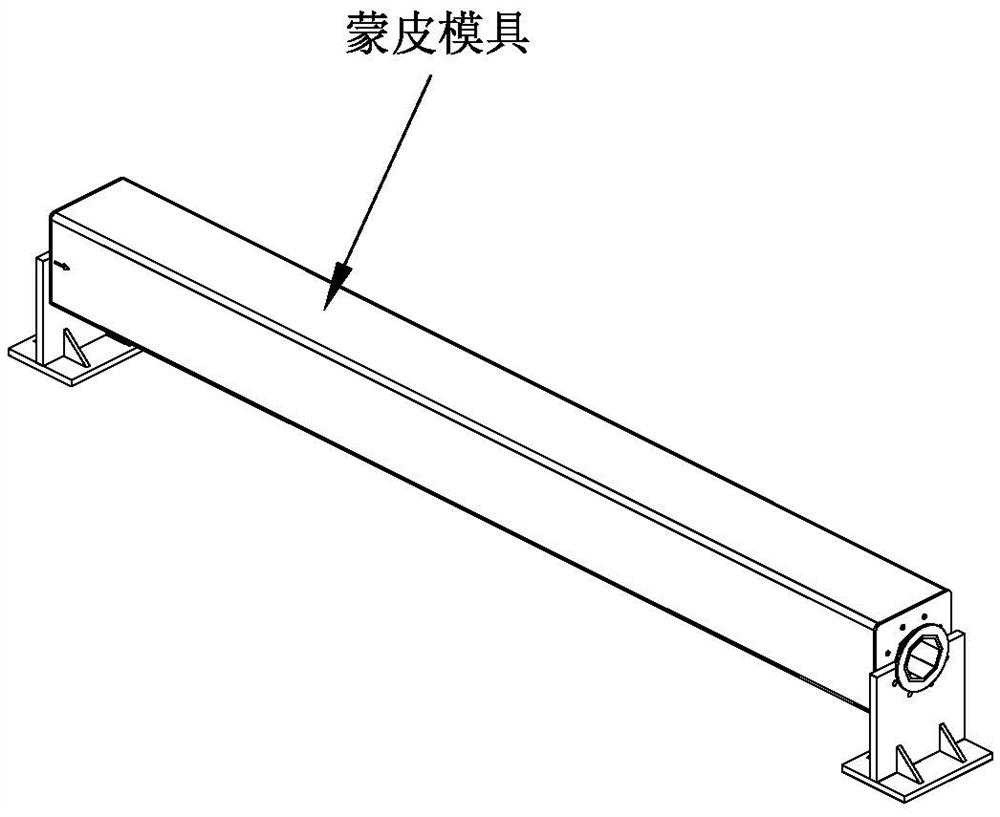

[0046] A box with a cross-sectional size of 430mm*430mm, a wall thickness of 5mm, and a length of 4500mm is made by prepreg laying and autoclave molding; the specific operation steps are as follows:

[0047] 1) According to the strength calculation result, use the automatic cutting machine to cut the plain weave prepreg and unidirectional prepreg required for the layup;

[0048] 2) Use a release agent to clean the surface of the metal mold;

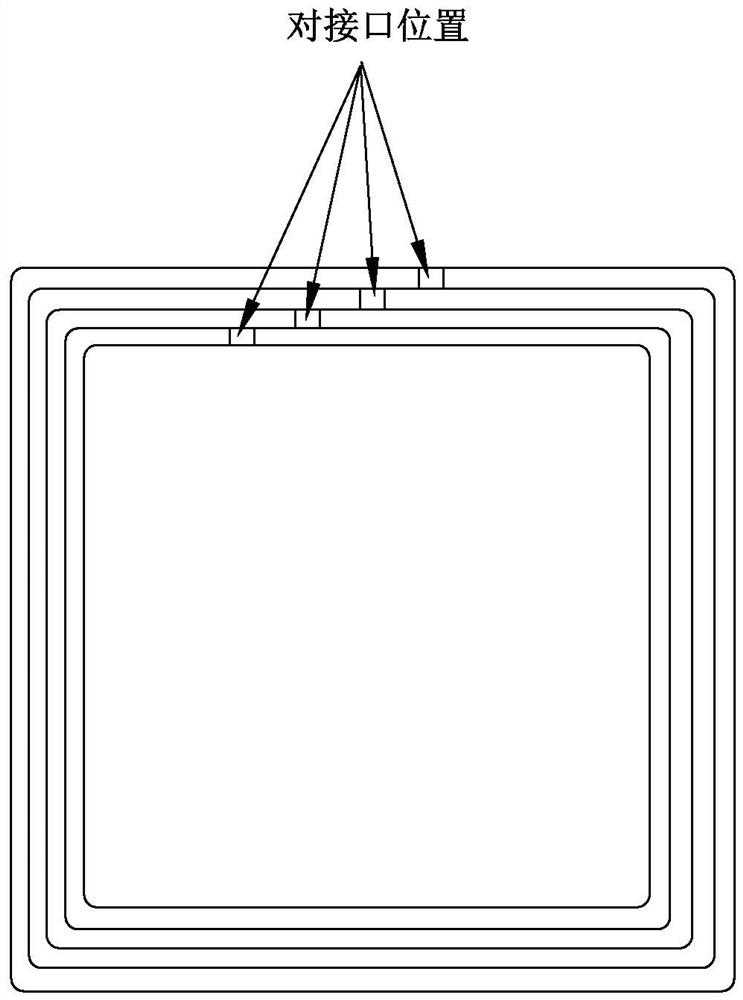

[0049] 3) Prepreg laying, after the first and third layers of prepreg laying are completed, lay the film;

[0050] 4) After the 20-layer prepreg is laid, put appropriate auxiliary materials on the surface of the prepreg and the L-shaped auxiliary die at the R angle;

[0051] 5) Winding of demoulding ring ribs to assist the demoulding of the composite material box, and use the winding process to form ring ribs with a height of about 50mm at both ends of the box mold;

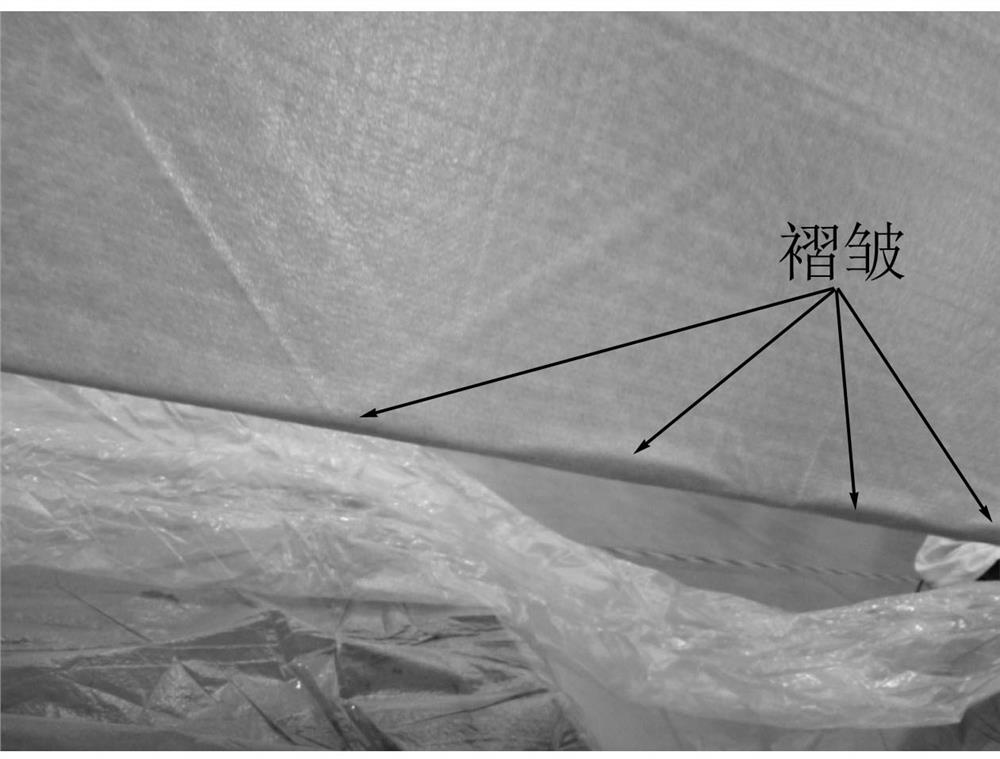

[0052]6) Put the vacuum bag into the tank for curing. Due to the larg...

Embodiment 2

[0057] A box with a cross-sectional size of 630mm*630mm, a wall thickness of 7mm, and a length of 6700mm is made by prepreg laying and autoclave molding. The specific operation steps are as follows:

[0058] 1) According to the strength calculation result, use the automatic cutting machine to cut the plain weave prepreg and unidirectional prepreg required for the layup;

[0059] 2) Use a release agent to clean the surface of the metal mold;

[0060] 3) Prepreg laying, after the first and third layers of prepreg laying are completed, lay the film;

[0061] 4) After the 28-layer prepreg is laid, put appropriate auxiliary materials and the L-shaped auxiliary die at the R angle on the surface of the prepreg;

[0062] 5) Winding of demoulding ring ribs to assist the demoulding of the composite material box, and use the winding process to form ring ribs with a height of about 50mm at both ends of the box mold;

[0063] 6) Put a vacuum bag into the tank for curing. Because the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com