Cold chain container capable of automatically unloading and monitoring system

A monitoring system and automatic unloading technology, applied in the direction of transmission system, packaging, measuring devices, etc., to achieve the effect of improving the effect of air-conditioning circulation, reducing the temperature, and increasing the distance between containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

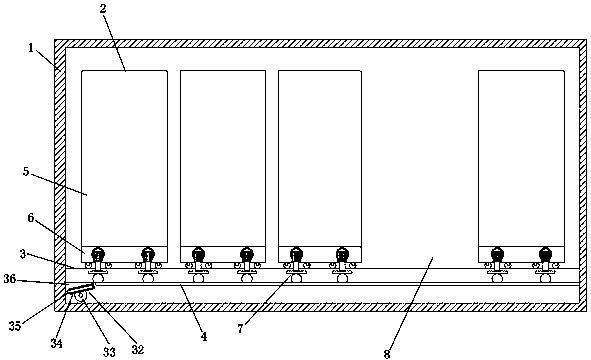

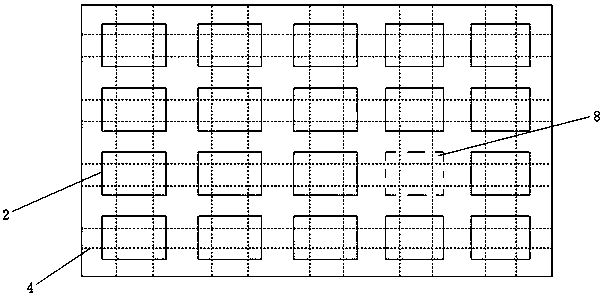

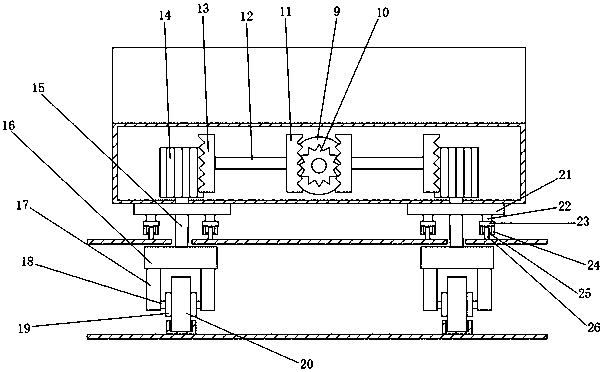

[0030] A cold chain container capable of automatic unloading and a monitoring system, characterized in that it includes a cold chain container 1, a container 2, a cold chain container monitoring system 28, a remote monitoring system 29, a cloud database 30, and a third-party query system 31; The cold chain container 1 is a general refrigerated container structure, and is provided with a refrigeration compressor system; a bottom plate 3 is provided inside the cold chain container 1; a track 4 is provided below the bottom plate 3; Telescopic unloading rack 32; the containers 2 are arranged in a regular matrix on the base plate 3; a space 8 is arbitrarily vacated in the matrix formed by the containers 2; the space of the space 8 is slightly larger than that of a container 2; The direction of the track 4 is divided into longitudinal and transverse; the longitudinal track 4 and the transverse track 4 intersect each other and correspond to the matrix formed by the container 2; the co...

Embodiment 2

[0041] The structure and principle of this embodiment 2 are basically the same as that of embodiment 1, the difference is that the moving device 7 also includes a bump 21; the bump 21 is arranged at the bottom of the container 2; the connecting rod 2 15 passes through the bump 21, but not in contact with the bump 21; the second wheel seat 23 is arranged on the bump 21. The bump 21 plays the role of raising, connecting and supporting the second wheel base 23 and the support wheel 26 .

Embodiment 3

[0043] The structure and principle of this embodiment 3 are basically the same as that of embodiment 1, except that the moving device 7 also includes a connecting rod three 22; the connecting rod three 22 is fixed on the bottom of the container 2; the wheel base two 23 is arranged on On the connecting rod three 22. The third connecting rod 22 plays a role of connecting and supporting the second wheel seat 23 and the supporting wheel 26 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com