Domestic wastewater recovery and treatment method

A domestic sewage, recycling and treatment technology, applied in the direction of biological water/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of difficulty in meeting the discharge standard of suspended solids, high investment cost of waste water treatment, and large footprint To improve the efficiency of sewage treatment, ensure full contact, and save land resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

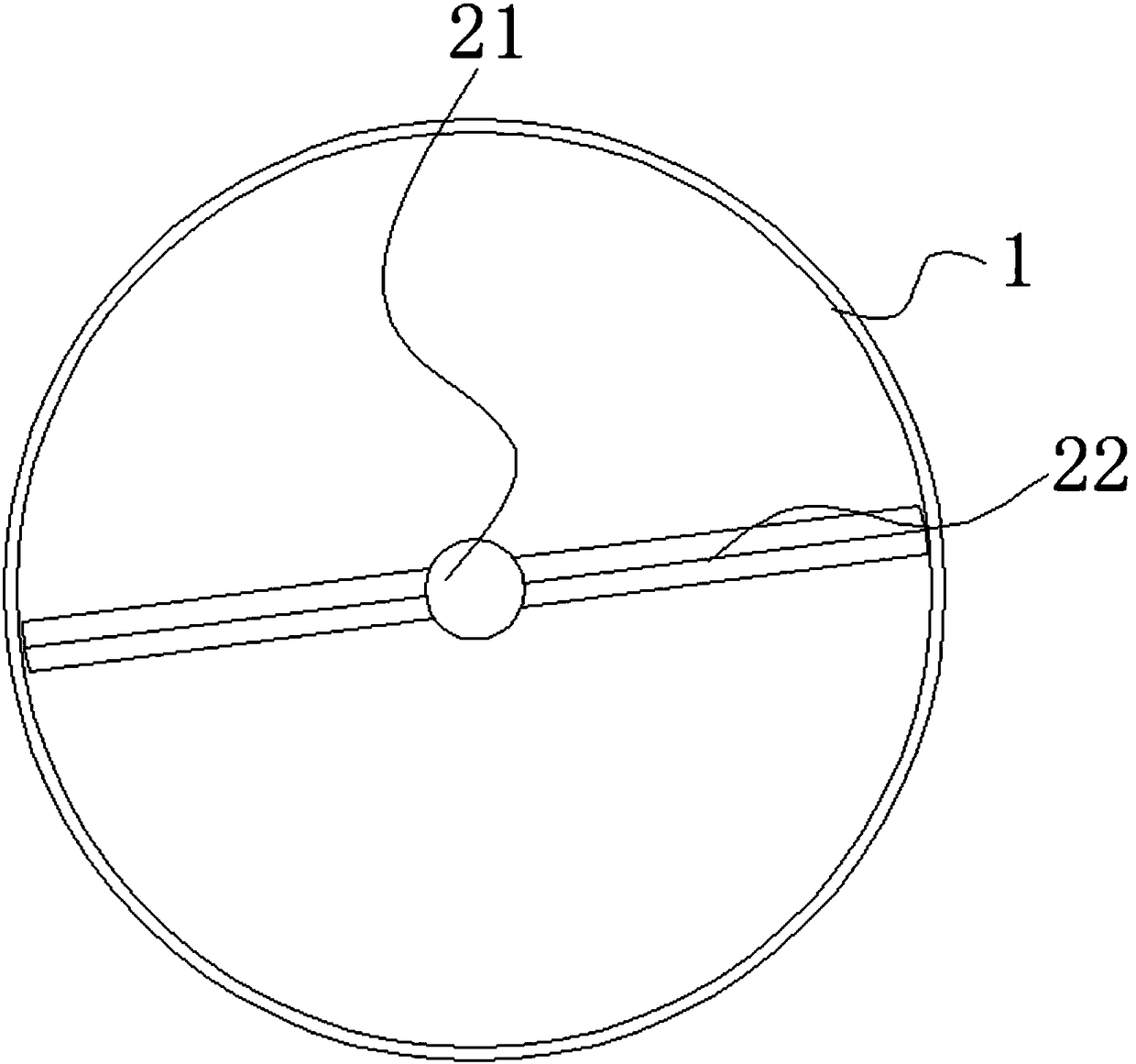

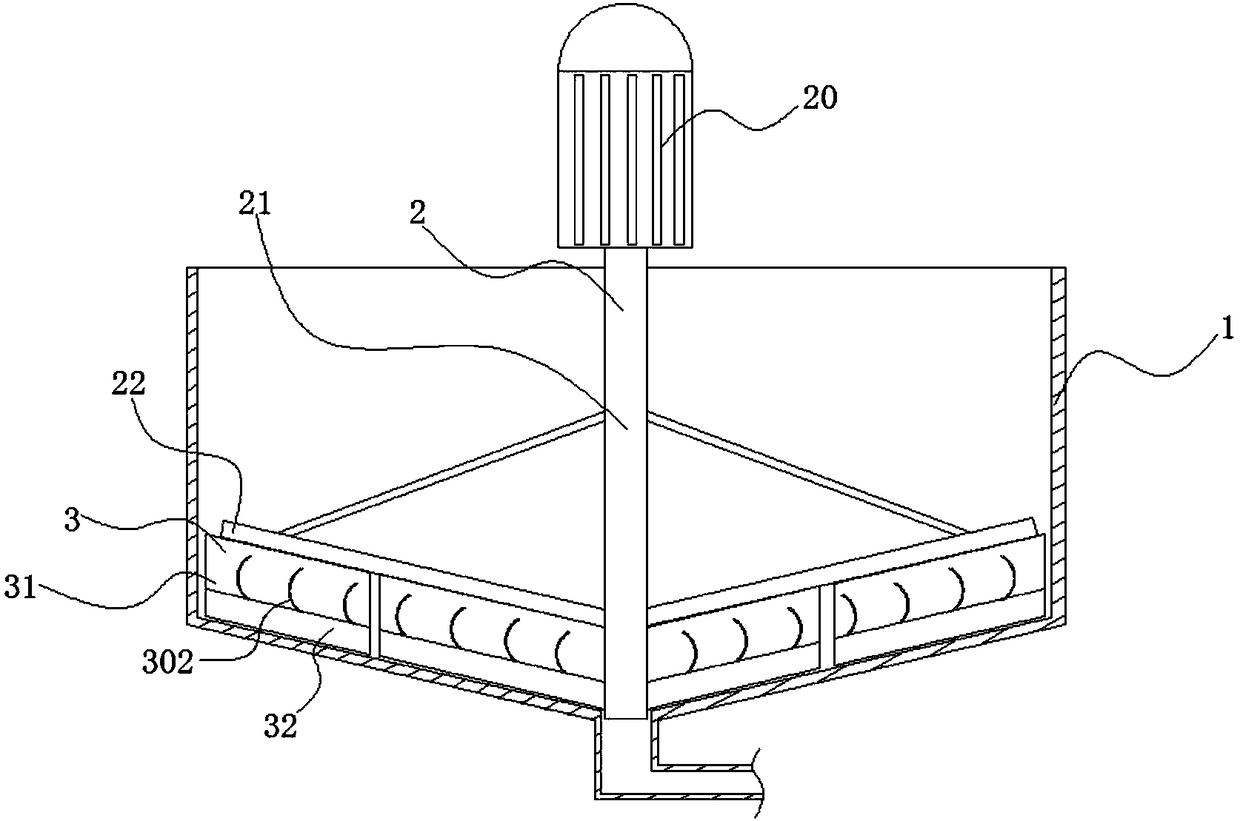

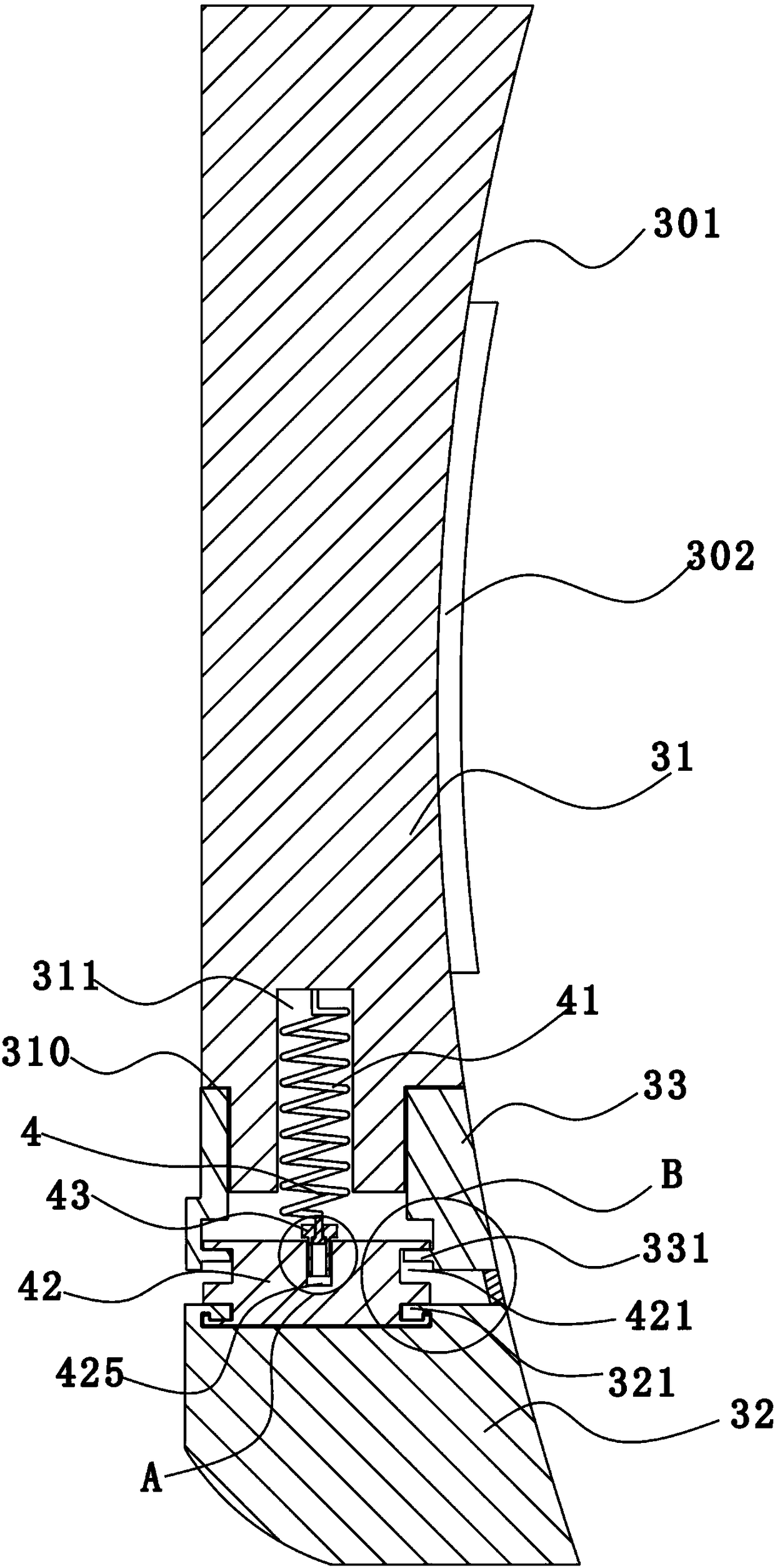

[0024] A method for recycling and treating domestic sewage, including the following steps: (1) After the sewage passes through the flocculation tank and the sedimentation tank, the clean water is raised to the biochemical tank; during the reaction in the flocculation tank, a flocculant needs to be added to the flocculation tank, specifically, the The flocculant is polyaluminum chloride; a mud scraping device 2 is provided in the sedimentation tank, and the sludge deposited on the bottom of the tank is scraped by the mud scraping device; (2) The biochemical tank is continuously aerated and reacted for 1 hour The aeration operation is specifically to pass gas into the biochemical tank through the aerator, and the gas can be called air or oxygen; specifically, the aeration time is 1.2h, and the aeration rate is 10L / h; the biochemical tank is filled with fillers, The filler is made of activated carbon fiber and polyethylene fiber, specifically, the weight ratio of activated carbon ...

Embodiment 2

[0032] A method for recycling and treating domestic sewage, including the following steps: (1) After the sewage passes through the flocculation tank and the sedimentation tank, the clean water is raised to the biochemical tank; during the reaction in the flocculation tank, a flocculant needs to be added to the flocculation tank, specifically, the The flocculant is polyaluminum chloride; the sedimentation tank is provided with a mud scraping device 2, through which the sludge deposited on the bottom of the tank is scraped off; (2) The biochemical tank is continuously aerated and reacted for 2 hours The aeration operation is specifically to pass gas into the biochemical tank through the aerator, and the gas can be called air or oxygen; specifically, the aeration time is 1.8h, and the aeration rate is 20L / h; the biochemical tank is filled with fillers, The filler is made of activated carbon fiber and polyethylene fiber, specifically, the weight ratio of activated carbon fiber and ...

Embodiment 3

[0035] A method for recycling and treating domestic sewage, including the following steps: (1) After the sewage passes through the flocculation tank and the sedimentation tank, the clean water is raised to the biochemical tank; during the reaction in the flocculation tank, a flocculant needs to be added to the flocculation tank, specifically, the The flocculant is polyaluminum chloride; the sedimentation tank is provided with a mud scraping device 2, through which the sludge deposited on the bottom of the tank is scraped off; (2) The biochemical tank is continuously aerated and reacted for 2 hours The aeration operation is specifically to pass gas into the biochemical tank through the aerator, and the gas can be called air or oxygen; specifically, the aeration time is 1.8h, and the aeration rate is 18L / h; the biochemical tank is filled with fillers, The filler is made of activated carbon fiber and polyethylene fiber, specifically, the weight ratio of activated carbon fiber and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com