Method for synthesizing bisindole derivative

A technology of bis-indole derivatives and indole derivatives, applied in organic chemistry and other fields, can solve the problems of harsh reaction conditions and high toxicity of aldehyde compounds, and achieve the effect of simple steps, low toxicity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

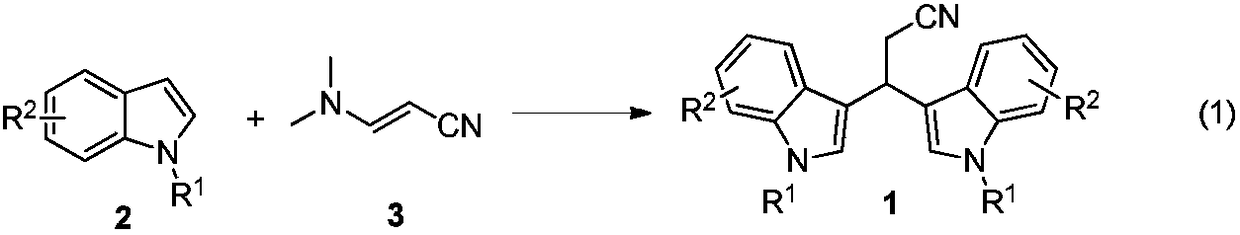

Method used

Image

Examples

Embodiment 1

[0031]

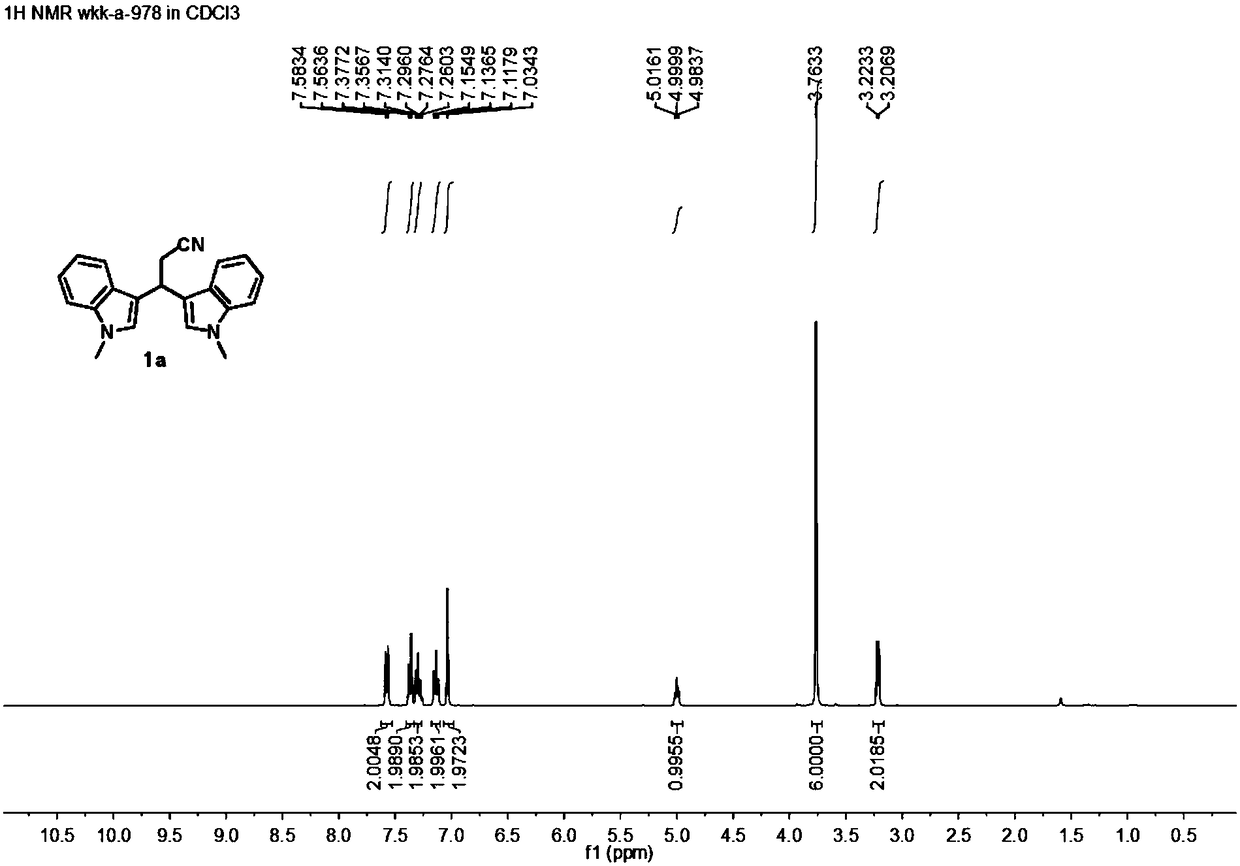

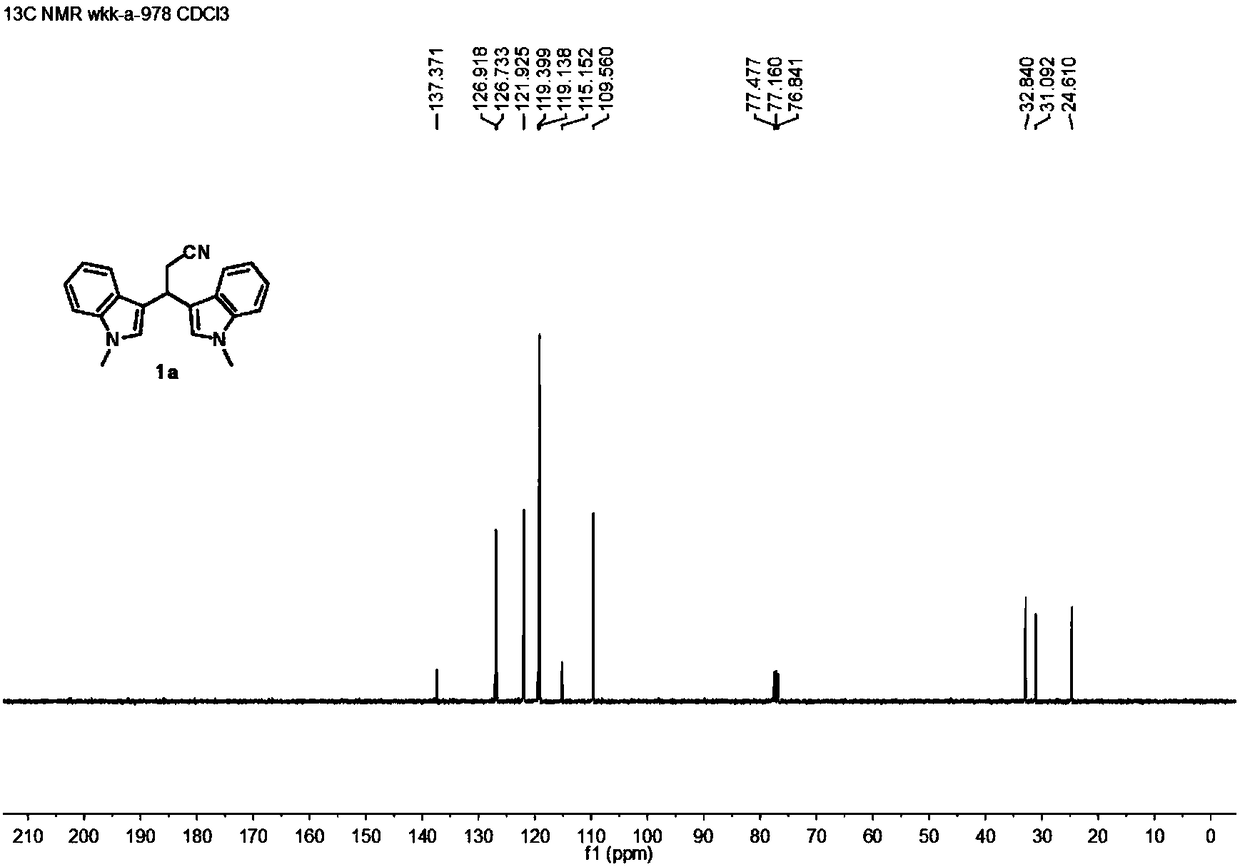

[0032] In a 10mL reaction flask, add N-methylindole (2a) (66mg, 0.5mmol), 3-dimethylaminoacrylonitrile (3) (48mg, 0.5mmol), dichloroacetic acid (645mg, 5.0mmol) in sequence ) and 2mL solvent dichloroethane, stirred at 50°C for 4h. After the reaction is completed, the reaction solution is poured into a separatory funnel, and 10 mL of saturated aqueous sodium bicarbonate solution is added thereto, shaken, left to stand, and the oil-water phase is separated, and the water phase is extracted with dichloromethane (2 × 5 mL), and the organic Mutually. The organic phases were mixed, dried over anhydrous sodium sulfate, and filtered. The volatile components were removed under reduced pressure, and then separated by silica gel column chromatography (dichloromethane as the eluent) to obtain the target product (1a) (128 mg, yield 82%) as a white solid. The target product was confirmed by NMR and high-resolution mass spectrometry. (Reaction 2)

Embodiment 2

[0034] The reaction steps and operations are the same as in Example 1, except that the reaction time is 12 hours. The reaction was stopped, and the target product 1a (127 mg, yield 81%) was obtained after post-treatment.

Embodiment 3

[0036] The reaction steps and operations are the same as in Example 1, except that the reaction time is 1 h. The reaction was stopped, and the target product 1a (47 mg, yield 30%) was obtained after post-treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com