Polyvinyl chloride environment-friendly color paste

A polyvinyl chloride, environmentally friendly technology, applied in the direction of pigment paste, coating, etc., can solve the problems of carcinogenicity, ecological environment and human health threats, and achieve uniform coloring, low manufacturing cost, and good economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

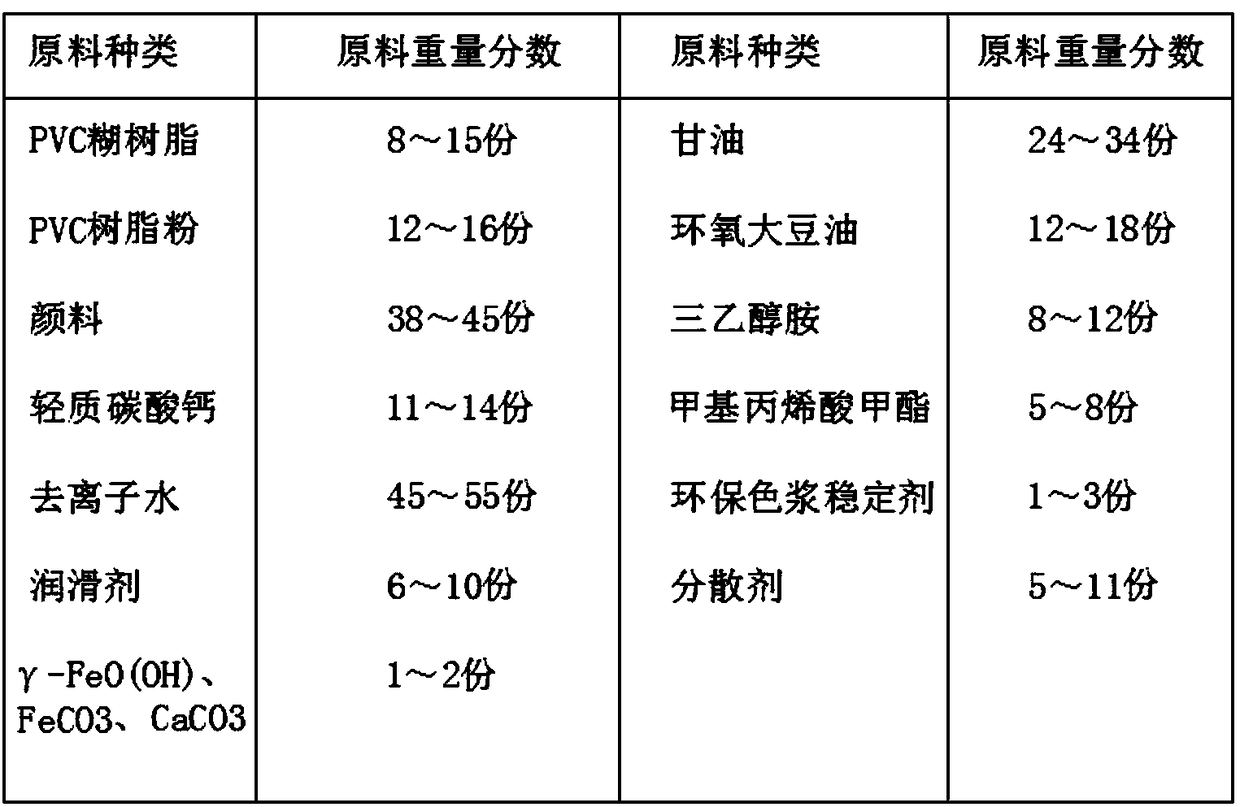

[0021] see figure 1 As shown, the technical solution adopted in the present invention is: a polyvinyl chloride environment-friendly color paste, which includes the following raw materials: 15 parts of PVC paste resin, 16 parts of PVC resin powder, 45 parts of pigment, light 14 parts of calcium carbonate, 55 parts of deionized water, 34 parts of glycerin, 18 parts of epoxidized soybean oil, 12 parts of triethanolamine and 8 parts of methyl methacrylate.

[0022] Wherein, the polyvinyl chloride environment-friendly color paste is also added with 3 parts of an environment-friendly color paste stabilizer.

[0023] Wherein, the environment-friendly color paste stabilizer includes 60% organotin stabilizer and 40% organozinc stabilizer.

[0024] Wherein, 10 parts of lubricants are also added in the polyvinyl chloride environment-friendly color paste, wherein the lubricant is a mixture of stearic acid, polyethylene glycol and glycerin and the ratio of stearic acid, polyethylene glyco...

Embodiment 2

[0028] see figure 1 As shown, the technical solution adopted in the present invention is: a polyvinyl chloride environment-friendly color paste, which includes the following raw materials: 8 parts of PVC paste resin, 12 parts of PVC resin powder, 38 parts of pigment, light 11 parts of calcium carbonate, 45 parts of deionized water, 24 parts of glycerin, 12 parts of epoxidized soybean oil, 8 parts of triethanolamine and 5 parts of methyl methacrylate.

[0029] Wherein, the polyvinyl chloride environment-friendly color paste is also added with 1 part of an environment-friendly color paste stabilizer.

[0030] Wherein, the environment-friendly color paste stabilizer includes 30% organotin stabilizer and 70% organozinc stabilizer.

[0031] Wherein, 6 parts of lubricants are also added in the polyvinyl chloride environment-friendly color paste, wherein the lubricant is a mixture of stearic acid, polyethylene glycol and glycerin and the ratio of stearic acid, polyethylene glycol an...

Embodiment 3

[0035] see figure 1 As shown, the technical solution adopted in the present invention is: a polyvinyl chloride environment-friendly color paste, which includes the following raw materials: 15 parts of PVC paste resin, 12 parts of PVC resin powder, 45 parts of pigment, light 11 parts of calcium carbonate, 55 parts of deionized water, 24 parts of glycerin, 18 parts of epoxidized soybean oil, 8 parts of triethanolamine and 8 parts of methyl methacrylate.

[0036] Wherein, the polyvinyl chloride environment-friendly color paste is also added with 1 part of an environment-friendly color paste stabilizer.

[0037] Wherein, the environment-friendly color paste stabilizer includes 60% organotin stabilizer and 40% organozinc stabilizer.

[0038] Wherein, 10 parts of lubricants are also added in the polyvinyl chloride environment-friendly color paste, wherein the lubricant is a mixture of stearic acid, polyethylene glycol and glycerin and the ratio of stearic acid, polyethylene glycol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com