Agitating type biological biogas fermentation tank

A biogas fermentation and biological technology is applied in the field of agitated biogas fermentation tanks, which can solve the problems that affect the continuous production and operation of fermentation tanks, cannot effectively solve the problems of material crusting, reduce biogas production, etc., so as to avoid crusting, reduce impurities, improve The effect of biogas volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

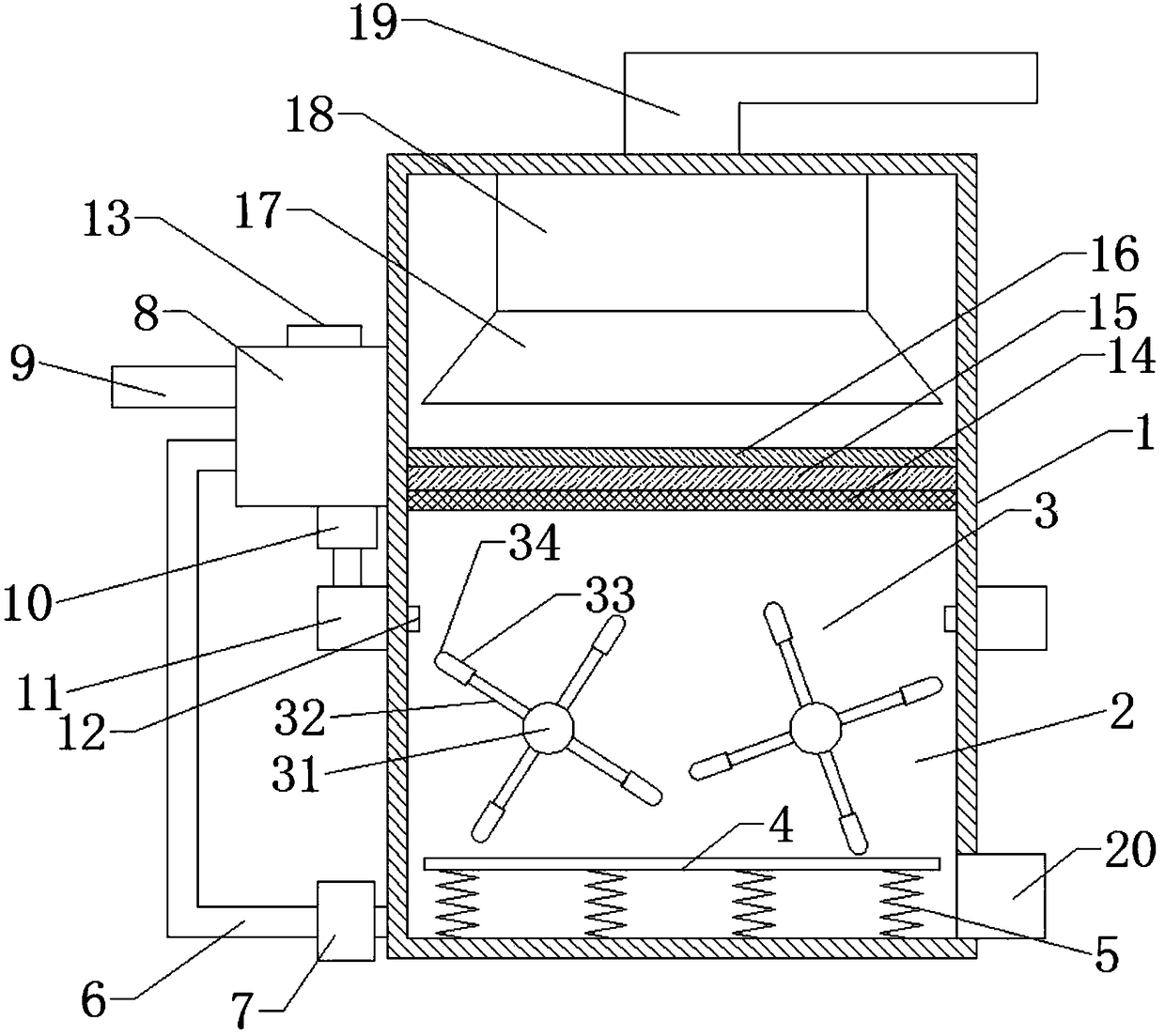

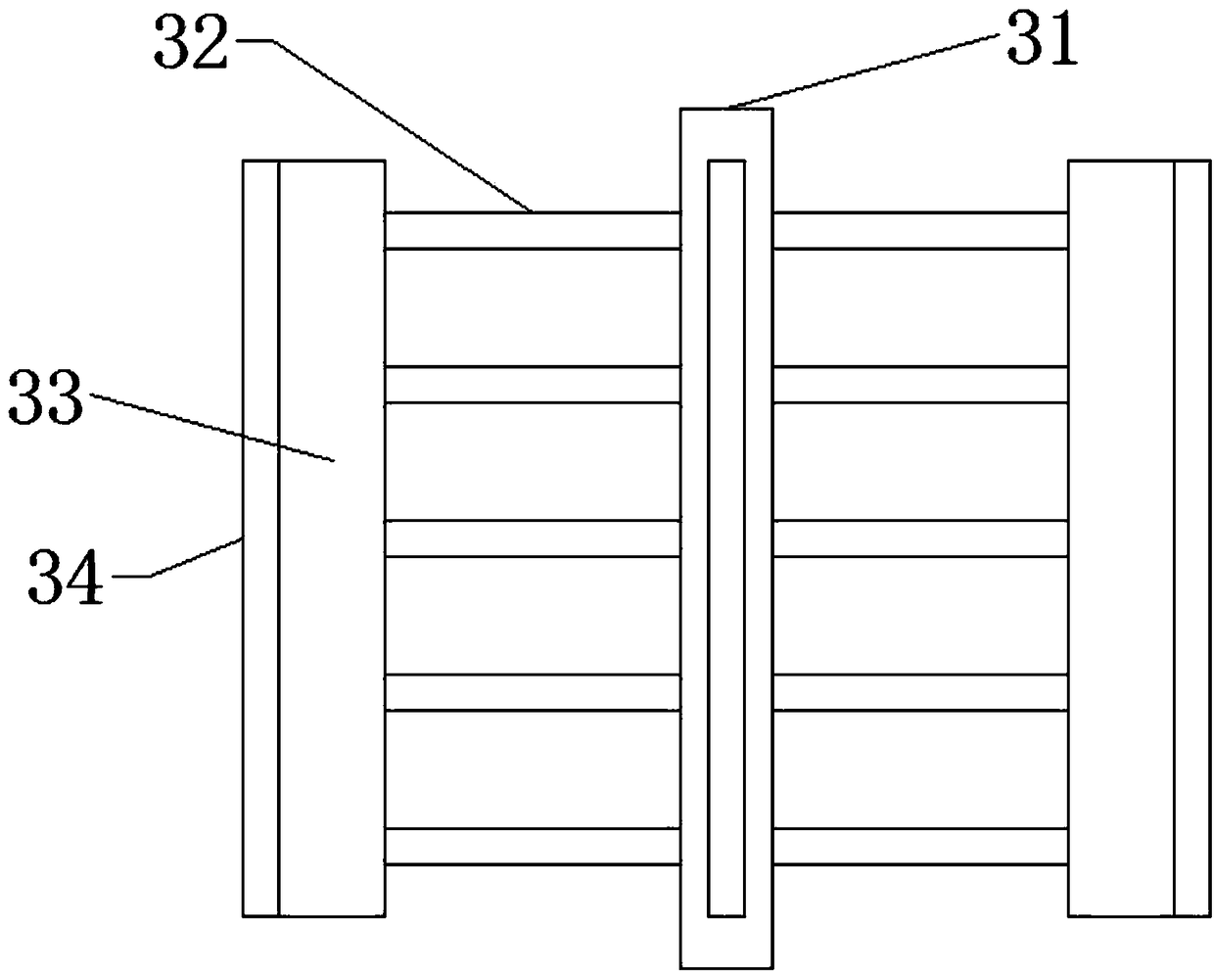

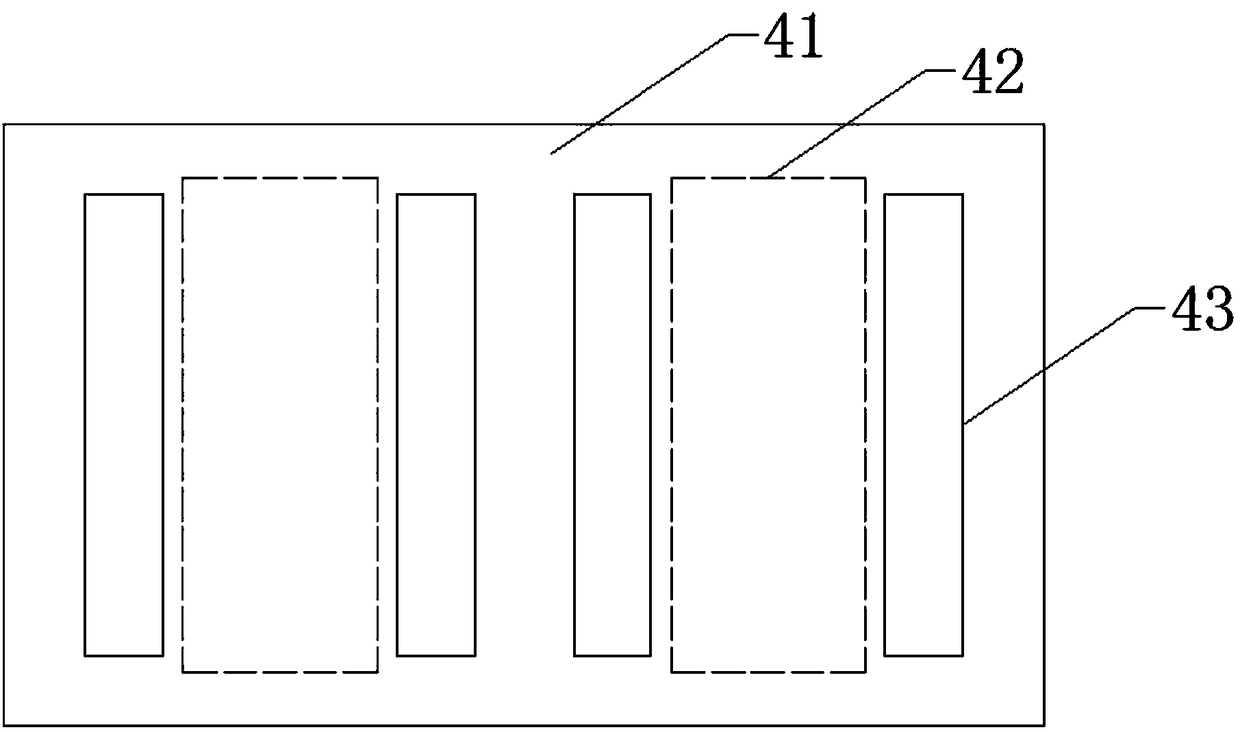

[0019] Please refer to the figure, in the embodiment of the present invention, an agitated biogas fermenter includes a tank body 1, a circulation pump 7, a feed pipe 9 and a discharge pipe 20; the bottom of the tank body 1 is set as a fermentation chamber 2, and the side wall is connected with a feed port with a sealed cover, the raw materials are loaded into the fermentation chamber 2, and the bottom of the tank body 1 is connected with a discharge pipe 20, which discharges the fermented raw materials for easy cleaning; Two groups of stirring mechanisms 3 are arranged in the stirring mechanism 3, and the outside of the stirring mechanism 3 is fixedly connected to the driving motor, and the stirring mechanism 3 is driven by the driving motor to stir the raw materials in the fermentation chamber 2; the stirring mechanism 3 includes a rotating shaft 31. Connecting rod 32, stirring plate 33 and arc-shaped end 34. Rotating shaft 31 is horizontally installed in tank body 1. Plate 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com