A kind of preparation method of spandex for paper diapers

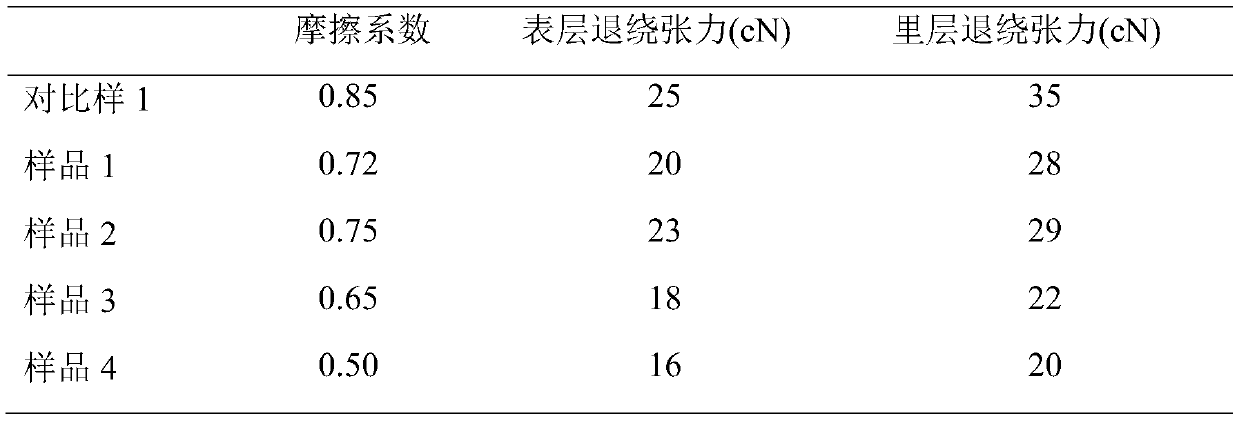

A technology of diapers and spandex, which is applied in the field of polyurethane elastic fiber preparation, can solve the problems of high fiber surface friction coefficient, easy adhesion between silk and silk, and large unwinding tension, so as to reduce adhesion between fibers, reduce surface static friction coefficient, Ensure the effect of unwinding tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

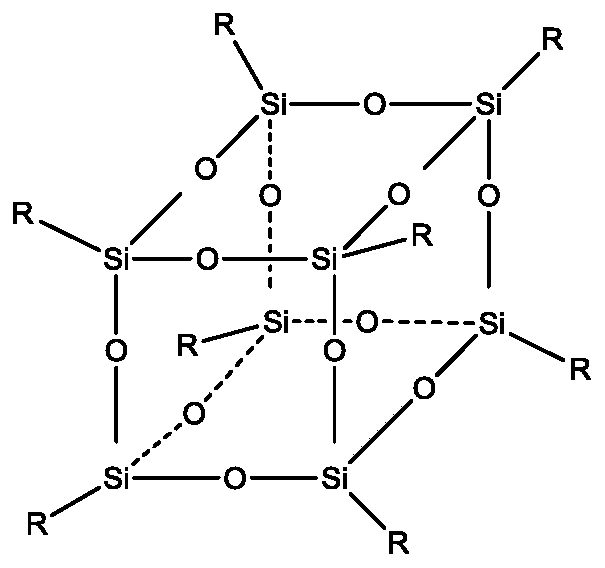

[0025] (1). Preparation of POSS solution. Add POSS and organic solvent together into a glass container, first use a mechanical stirrer to mix at a high speed for 0.5-2 hours, and then use an ultrasonic vibration disperser to conduct the mixed solution for 1-3 hours to obtain a uniformly dispersed POSS solution.

[0026] (2). Preparation of mixed spinning dope. The POSS solution is added to the polyurethane urea solution, and the solution is stirred and mixed for 24-48 hours under a constant temperature of 40-60 degrees to obtain a spandex spinning stock solution.

[0027] (3). Preparation of spandex for diapers. The spinning dope is transported to the spinneret assembly, and then passes through the fine holes of the spinneret to form a dope stream; the dope stream then evaporates the organic solvent through the spinning tunnel at 240-260 degrees to become primary fibers; The twister twists and hugs into a bundle, and is drawn by the wire guide roller, and is wound by the win...

Embodiment 1

[0040] With Band-CH 2 CH 2 CF 3 1.5kg of the POSS compound of the functional group and 5.0kg of dimethylacetamide were added to the reaction tank, firstly, a mechanical stirrer was used to stir and mix at a high speed for 2 hours, and then an ultrasonic vibration disperser was used to carry out ultrasonic treatment to the mixed solution for 1 hour to obtain a concentration of 20% POSS solution. The POSS solution was added to the polyurethaneurea solution with a concentration of 35%, and the mass ratio of POSS to polyurethaneurea was 1 / 99. and stirring and mixing for 28 hours at a constant temperature of 45 degrees, and obtaining a mixed spinning dope after the maturation is completed. The spinning dope is transported to the spinneret assembly, and then passes through the spinneret pores to form a dope stream; the dope stream passes through a 260-degree spinning tunnel to evaporate the solvent to become primary fibers; 48 primary fibers are rubbed through an air false twiste...

Embodiment 2

[0042] The same experimental method as in Example 1 is adopted, except that the functional group of POSS is -CH 2 CH 2 CH(CF 3 ) 2 , the obtained spandex for diapers is recorded as sample 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com