Environmentally-friendly silkete penetrating agent and production method thereof

A mercerizing penetrant, an environmentally friendly technology, used in textiles and papermaking, fiber processing, plant fibers, etc., can solve the problems of large foam, environmental damage, poor wetting and permeability, and achieve excellent alkali resistance, wetting and penetrating properties. The effect of good penetration, fast wetting and penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

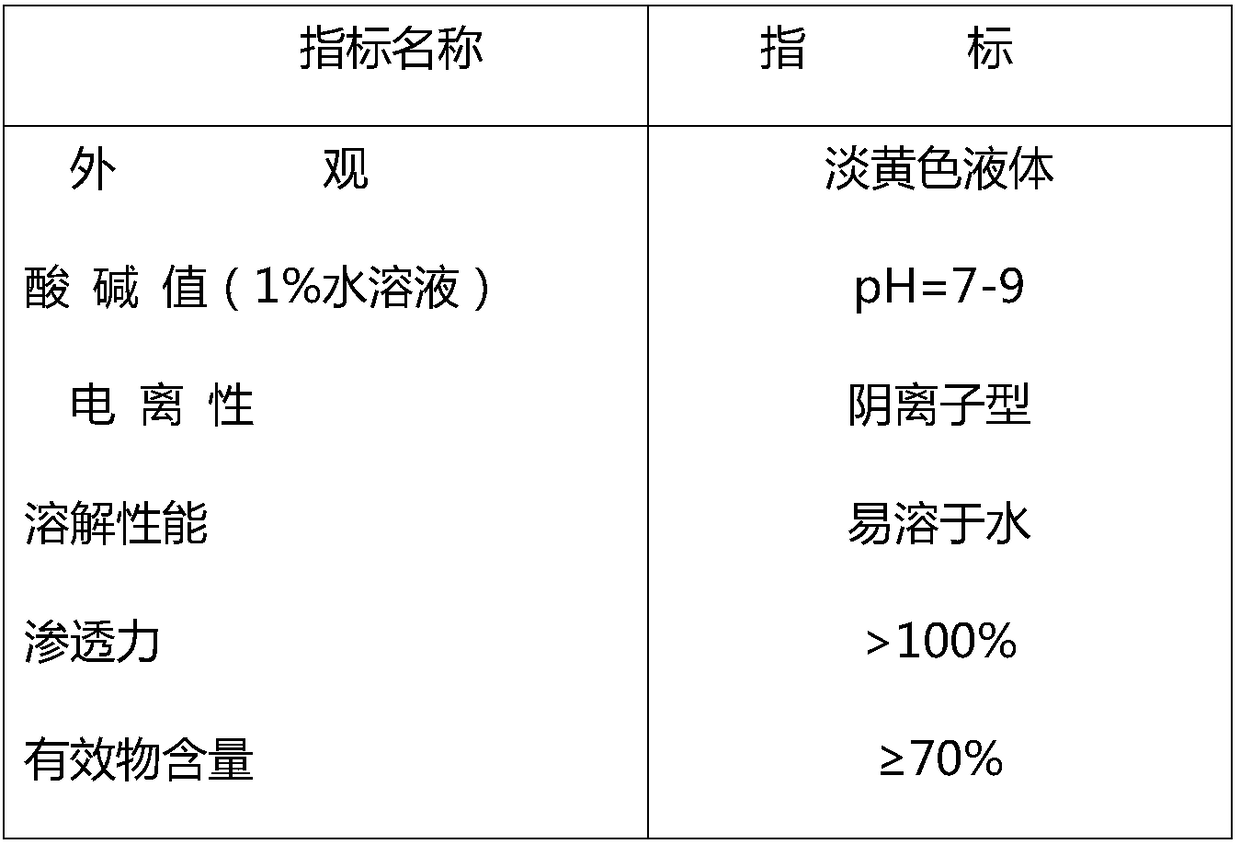

Image

Examples

Embodiment 1

[0028] The present invention is an environment-friendly mercerizing penetrant, which is compounded by three surfactants and water, and the components and mass percentages are as follows: 10% alkyl alcohol sulfate sodium salt, alkyl phosphate polyoxyethylene ether 50%, fatty alcohol polyoxyethylene ether 10%, water 30%.

[0029] Wherein, the alkyl alcohol is a natural alcohol of C10-12; the alkyl group in the alkyl phosphonate is C8; the fatty alcohol is a natural fatty alcohol of C8-10; the polymerization number of the alkyl phosphate polyoxyethylene ether is 3- 5; The polymerization number of fatty alcohol polyoxyethylene ether is 6-7.

[0030] The production method of above-mentioned environment-friendly mercerizing penetrating agent:

[0031] Add water to the reaction kettle first, then add alkyl alcohol sulfate sodium salt, alkyl phosphate polyoxyethylene ether, and fatty alcohol polyoxyethylene ether in turn under stirring, raise the temperature to about 55°C to dissolve...

Embodiment 2

[0033] The present invention is an environment-friendly mercerizing penetrant, which is compounded by three surfactants and water, and the components and mass percentages are as follows: 15% alkyl alcohol sulfate sodium salt, alkyl phosphate polyoxyethylene ether 40%, fatty alcohol polyoxyethylene ether 5%, water 40%.

[0034] Wherein, the alkyl alcohol is a natural alcohol of C10-12; the alkyl group in the alkyl phosphonate is C8; the fatty alcohol is a natural fatty alcohol of C8-10; the polymerization number of the alkyl phosphate polyoxyethylene ether is 3- 5; The polymerization number of fatty alcohol polyoxyethylene ether is 6-7.

[0035] The production method of above-mentioned environment-friendly mercerizing penetrating agent:

[0036] Add water to the reaction kettle first, then add alkyl alcohol sulfate sodium salt, alkyl phosphate polyoxyethylene ether, fatty alcohol polyoxyethylene ether in turn under stirring, raise the temperature to about 60°C to dissolve them...

Embodiment 3

[0038] The present invention is an environment-friendly mercerizing penetrant, which is compounded by three surfactants and water, and the components and mass percentages are as follows: 5% alkyl alcohol sulfate sodium salt, alkyl phosphate polyoxyethylene ether 60%, fatty alcohol polyoxyethylene ether 15%, water 20%.

[0039] Wherein, the alkyl alcohol is a natural alcohol of C10-12; the alkyl group in the alkyl phosphonate is C8; the fatty alcohol is a natural fatty alcohol of C8-10; the polymerization number of the alkyl phosphate polyoxyethylene ether is 3- 5; The polymerization number of fatty alcohol polyoxyethylene ether is 6-7.

[0040] The production method of above-mentioned environment-friendly mercerizing penetrating agent:

[0041] Add water to the reaction kettle first, then add alkyl alcohol sulfate sodium salt, alkyl phosphate polyoxyethylene ether, and fatty alcohol polyoxyethylene ether in turn under stirring, raise the temperature to about 50°C to dissolve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com