Preparation method and application of packaging material for preventing fried chips from being softened and mildewed

A technology of french fries and composite packaging, applied in household packaging, chemical instruments and methods, applications, etc., can solve problems such as inability to keep fresh, lose flavor, and easy mold in fried french fries, so as to protect the taste and quality and prolong the shelf life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

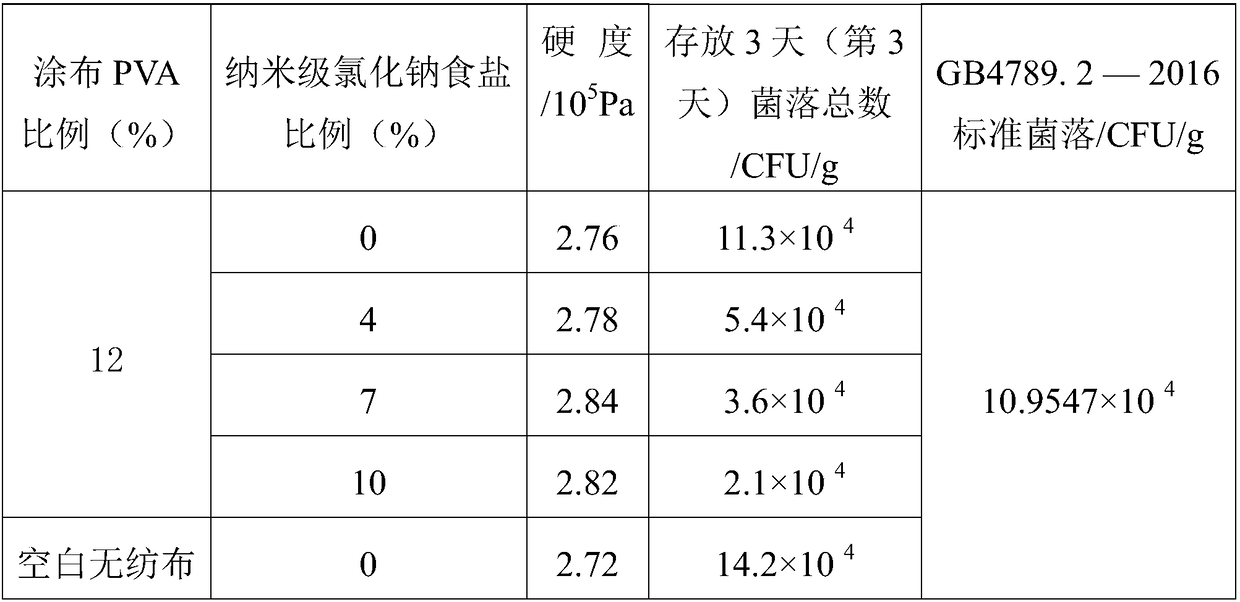

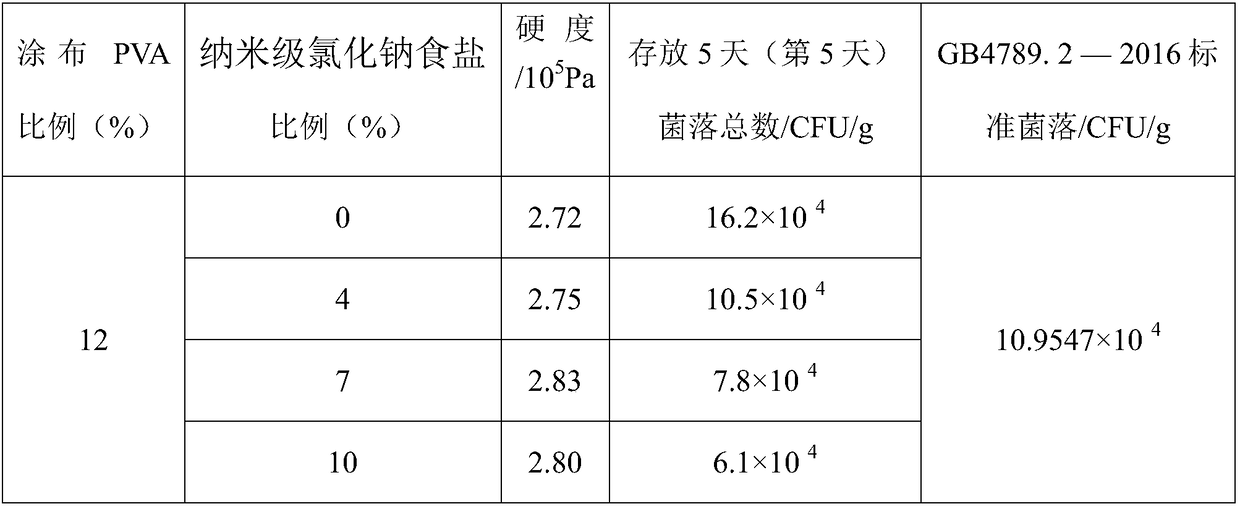

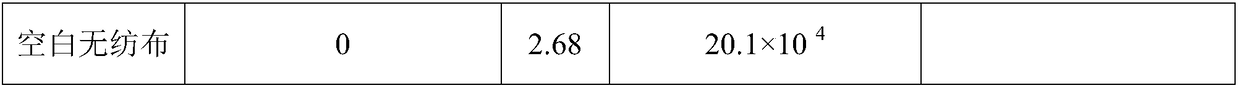

Embodiment 1

[0024] A method for preparing a composite packaging modified non-woven fabric to prevent fried French fries from softening and moldy, which is completed by the following steps:

[0025] The first step is to prepare materials: select 1799 type PVA resin, food-grade non-woven fabric, select nano-scale sodium chloride salt, and select purified water at room temperature for backup;

[0026] The second step, dissolving: take 60~75kg of purified water at room temperature 20°C for the first step and add it to the reactor, add nano-scale sodium chloride salt into the reactor and stir to fully dissolve, nano-scale sodium chloride salt Prepare with 4% by weight percentage of pure water, get the spare PVA resin in the first step, add PVA resin to the above-mentioned reaction kettle, prepare PVA resin with 6% by weight percentage of pure water, then heat to 90°C and stir for 4 Hours, make the PVA resin fully dissolved in the reaction kettle, make the PVA resin and nano-scale sodium chlori...

Embodiment 2

[0030] A method for preparing a composite packaging modified non-woven fabric to prevent fried French fries from softening and moldy, which is completed by the following steps:

[0031] The first step is to prepare materials: select 1788 type PVA resin, food-grade non-woven fabric, select nano-scale sodium chloride salt, and select purified water at room temperature for backup;

[0032] The second step, dissolving: take 60~75kg of purified water at room temperature 20°C for the first step and add it to the reactor, add nano-scale sodium chloride salt into the reactor and stir to fully dissolve, nano-scale sodium chloride salt Prepare with 7% by weight percentage of pure water, take the spare PVA resin in the first step, add PVA resin to the above-mentioned reaction kettle, prepare PVA resin with 9% by weight percentage of pure water, then heat to 90°C and stir for 5 Hours, make the PVA resin fully dissolved in the reaction kettle, make the PVA resin and nano-scale sodium chlor...

Embodiment 3

[0036] A method for preparing a composite packaging modified non-woven fabric to prevent fried French fries from softening and moldy, which is completed by the following steps:

[0037] The first step is to prepare materials: select 1799 type PVA water-absorbing resin, food-grade non-woven fabric, select nano-scale sodium chloride salt, and select purified water at room temperature for standby;

[0038] The second step, dissolving: take 60~75kg of purified water at room temperature 20°C for the first step and add it to the reactor, add nano-scale sodium chloride salt into the reactor and stir to fully dissolve, nano-scale sodium chloride salt Prepare with 10% by weight percentage of pure water, take the spare PVA resin in the first step, add PVA resin to the above-mentioned reaction kettle, prepare PVA resin with 12% by weight percentage of pure water, then heat to 90°C and stir for 6 Hours, make the PVA resin fully dissolved in the reaction kettle, make the PVA resin and nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com