Capacitance level sensor online measuring system and method thereof

A technology of liquid level sensor and measurement system, which is applied in the direction of liquid/fluid solid measurement, liquid level indicator and measuring device for physical variable measurement, which can solve the problems of weak anti-interference ability, poor precision, and large temperature influence, etc. Achieve the effect of good anti-stray capacitance performance, simple circuit and convenient calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

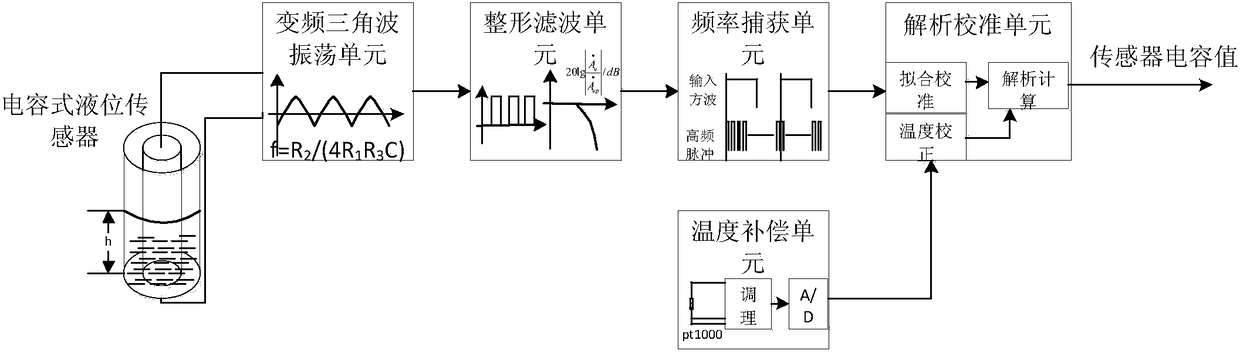

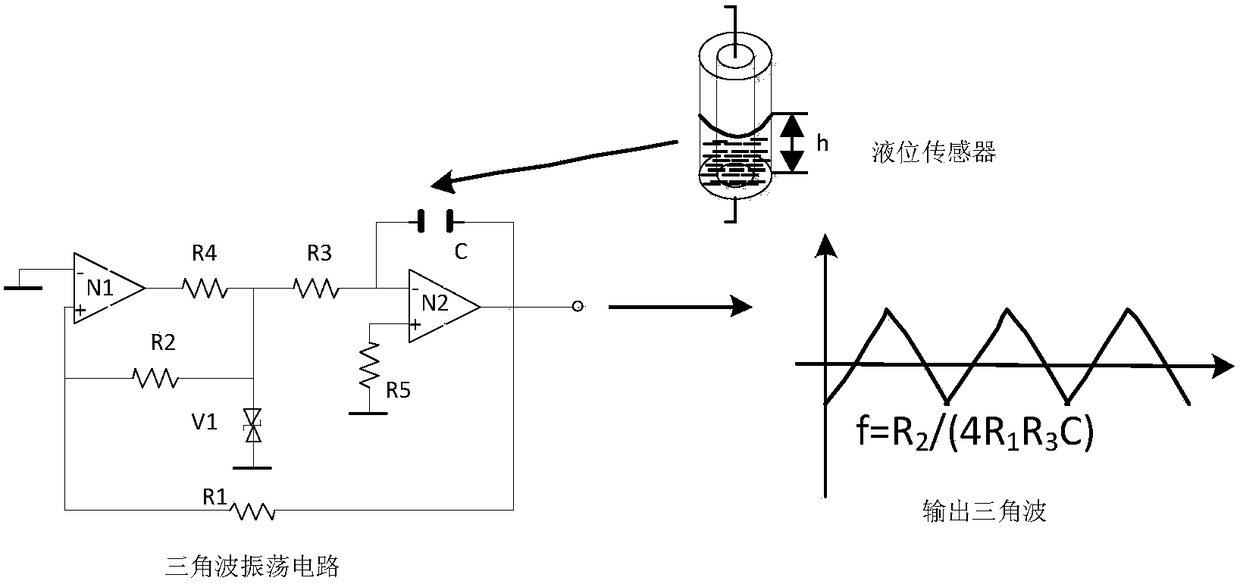

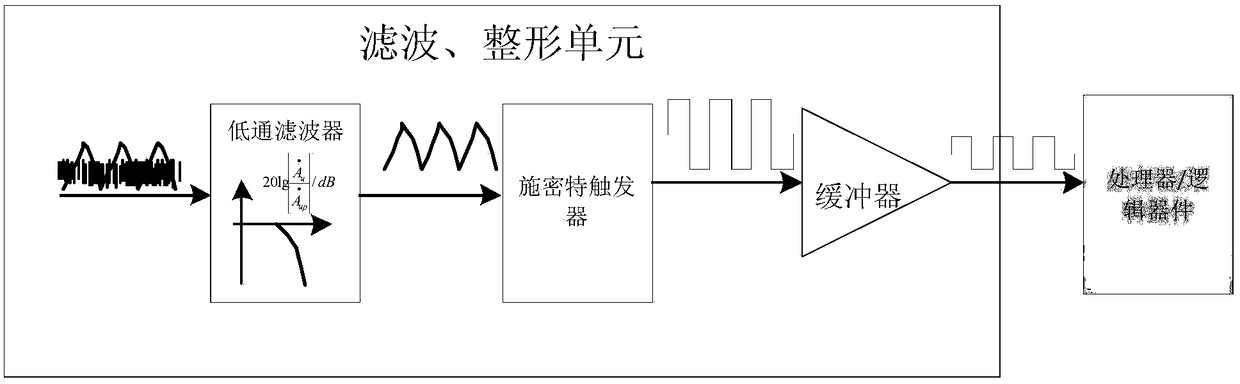

[0034] Please also see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 ,in, figure 1 It is a functional principle block diagram of the present invention, figure 2 It is a schematic diagram of frequency conversion triangular wave oscillation unit, image 3 is the schematic diagram of the shaping and filtering unit, Figure 4 is a schematic diagram of the frequency capture principle, Figure 5 is the schematic diagram of the temperature compensation unit, Figure 6 is a schematic diagram of the analytical calibration unit.

[0035] From figure 1 It can be seen that the online measurement method and system of the capacitive liquid level sensor are composed of a frequency conversion triangular wave oscillation unit, a filtering and shaping unit, a frequency acquisition unit, a temperature compensation unit, and an analysis and cali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com