Working system and method of laser engraving machine based on cloud load balancing control

A laser engraving machine, load balancing technology, applied in general control systems, control/regulation systems, digital control and other directions, can solve the problems of limited computing, processing capacity, difficulty in large-scale application, failure of engraving tasks, etc., to reduce labor management, reducing potential threats, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

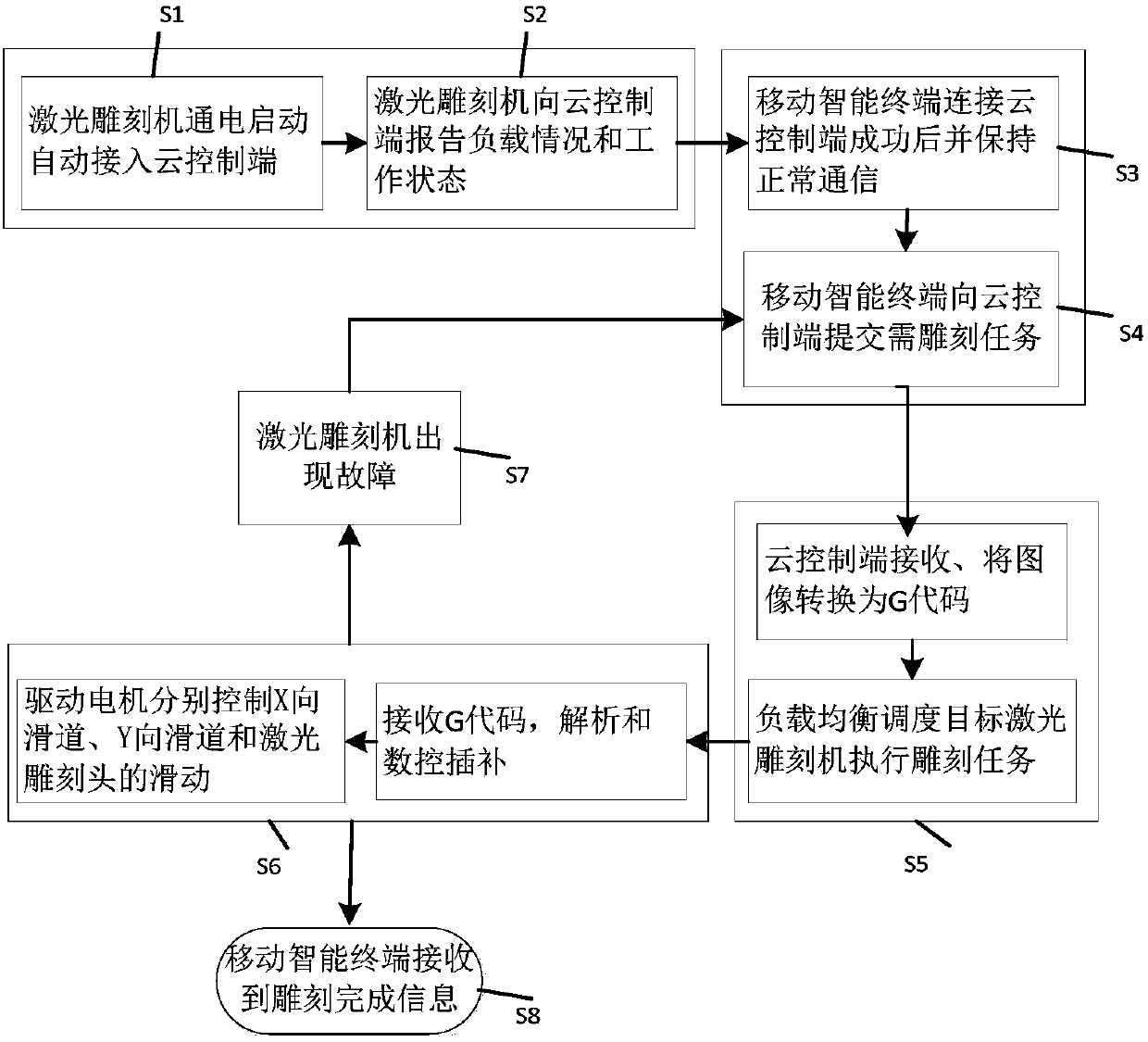

[0060] The technical solutions and beneficial effects of the present invention will be described in detail below in conjunction with the accompanying drawings.

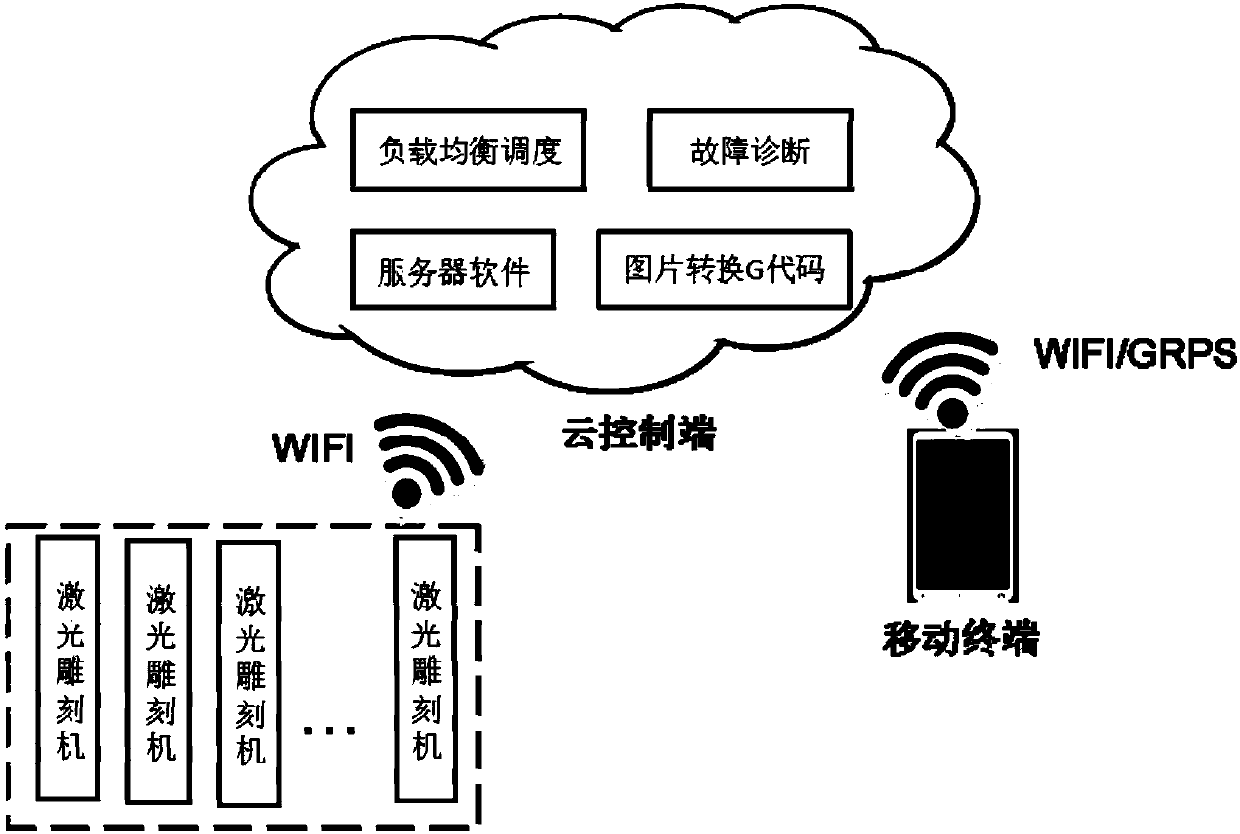

[0061] The present invention provides a laser engraving machine working system based on cloud load balancing control, which includes several laser engraving machines, a cloud control terminal and several mobile intelligent terminals, which will be introduced separately below.

[0062] The laser engraving machine has a built-in controller module, a laser control module, a motor drive module, a wireless transceiver module, a data acquisition module, a power supply module and an auxiliary module. The controller module is the core of the control and data processing of the laser engraving machine; the laser control module is responsible for protecting and driving the laser head; the motor drive module is responsible for driving the X-axis and Y-axis movement of the stepping motor; the wireless The transceiver module is res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com