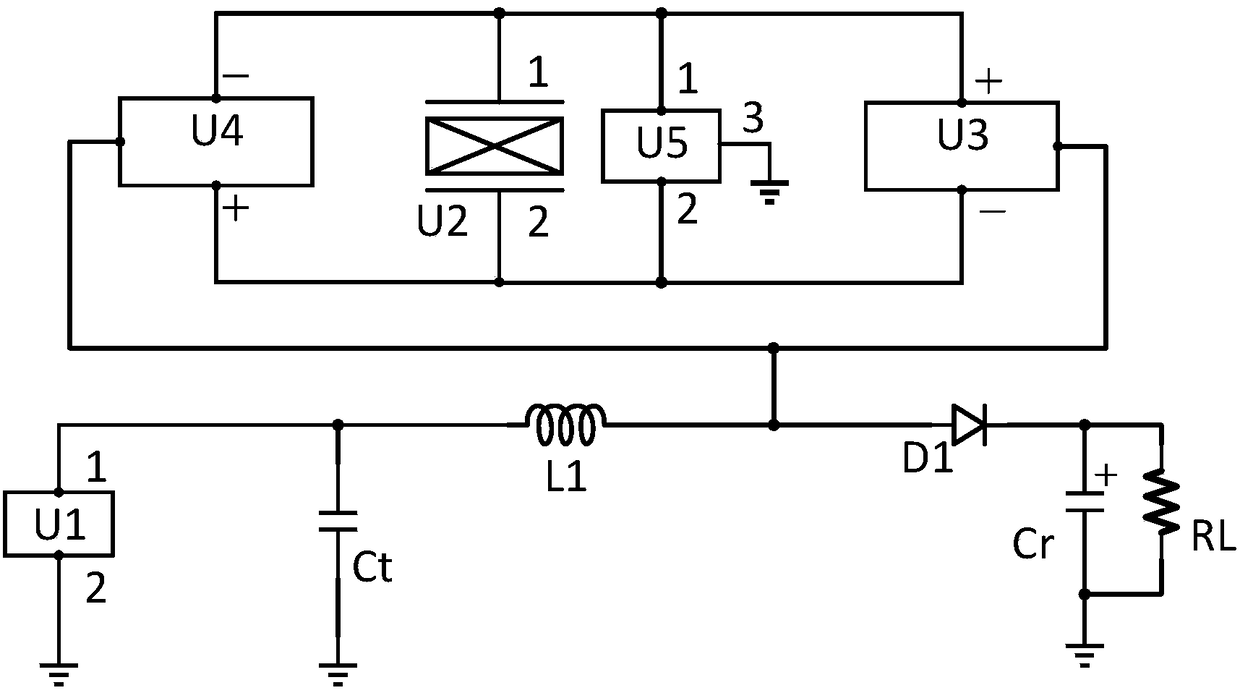

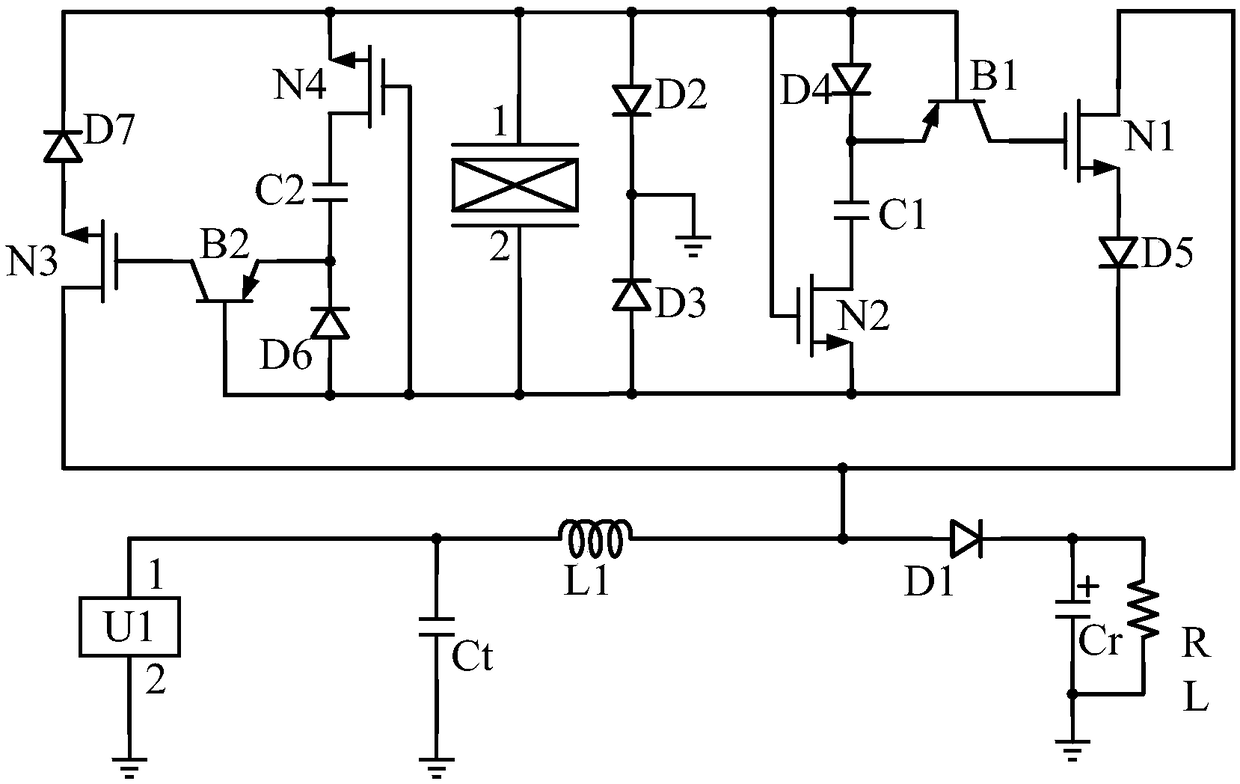

Compound energy collecting circuit

A technology for collecting circuits and composite energy, which is applied in the direction of current collectors, circuit devices, battery circuit devices, etc., can solve the problems of affecting collection efficiency, collection efficiency load impact, and low circuit collection efficiency, so as to reduce the cost of use and improve energy collection efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0012] A composite energy collection circuit, comprising a thermoelectric power generation sheet U1, a piezoelectric sheet U2, a positive peak detection module U3, a negative peak detection module U4, a zero potential switching module U5, a first inductor L1, a first diode D1, a first The energy storage capacitor Ct, the second energy storage capacitor Cr and the load RL are connected to the first pin of the thermoelectric generator U1, one end of the first energy storage capacitor Ct and one end of the first inductance L1, and the other end of the first inductance L1, The input terminal of the positive peak detection module U3, the input terminal of the negative peak detection module U4 and the anode of the first diode D1 are connected, the negative pole of the first diode D1, the positive pole of the second energy storage capacitor Cr and one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com