Single-stage LED driving circuit integrated with Cuk and LLC voltage reduction circuits

A LED drive and circuit technology, applied in the direction of high-efficiency power electronic conversion, electric light source, electrical components, etc., can solve the problems of high cost and poor reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

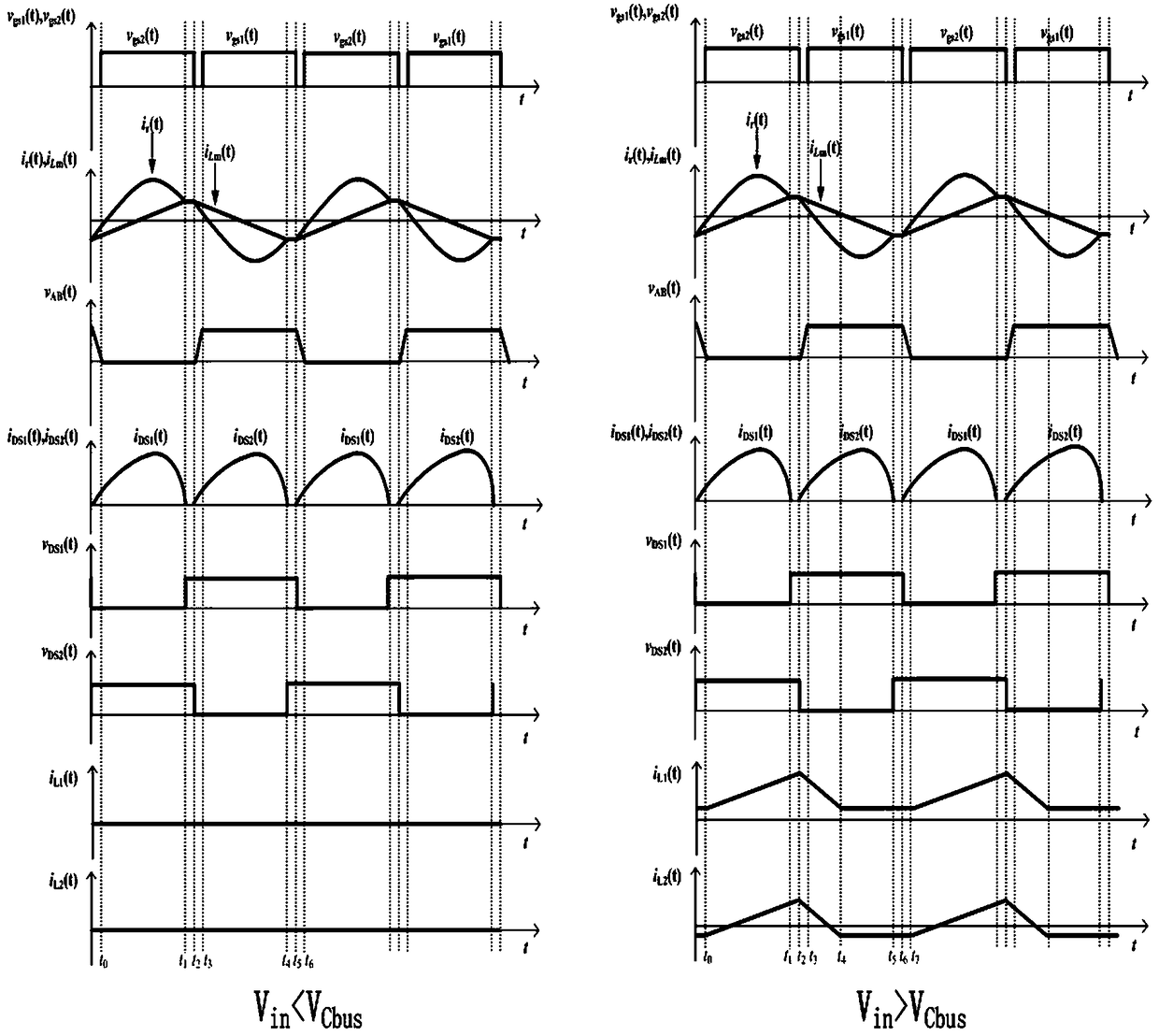

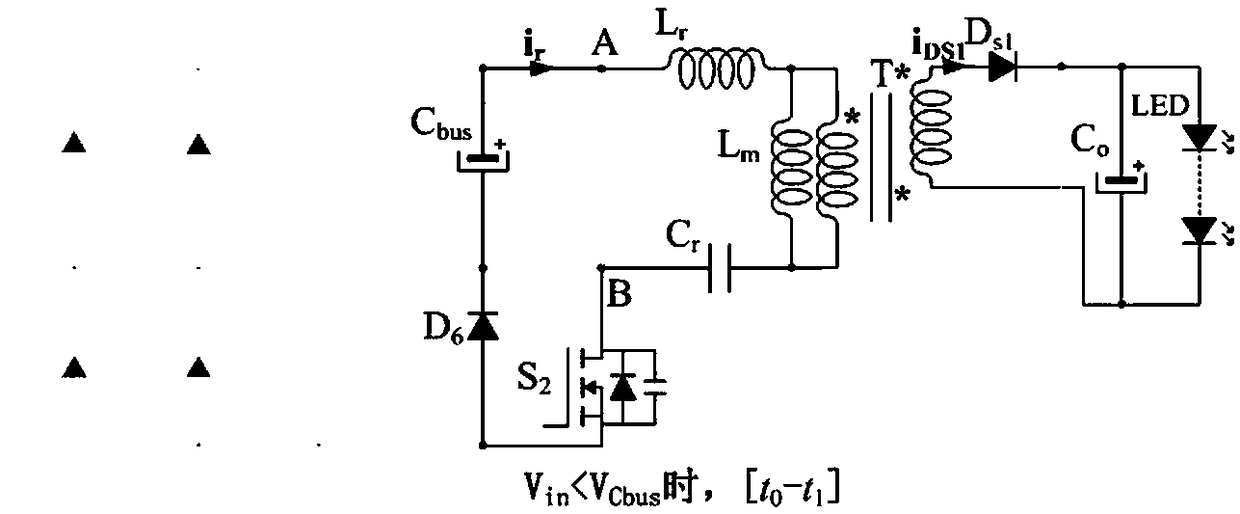

[0050] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

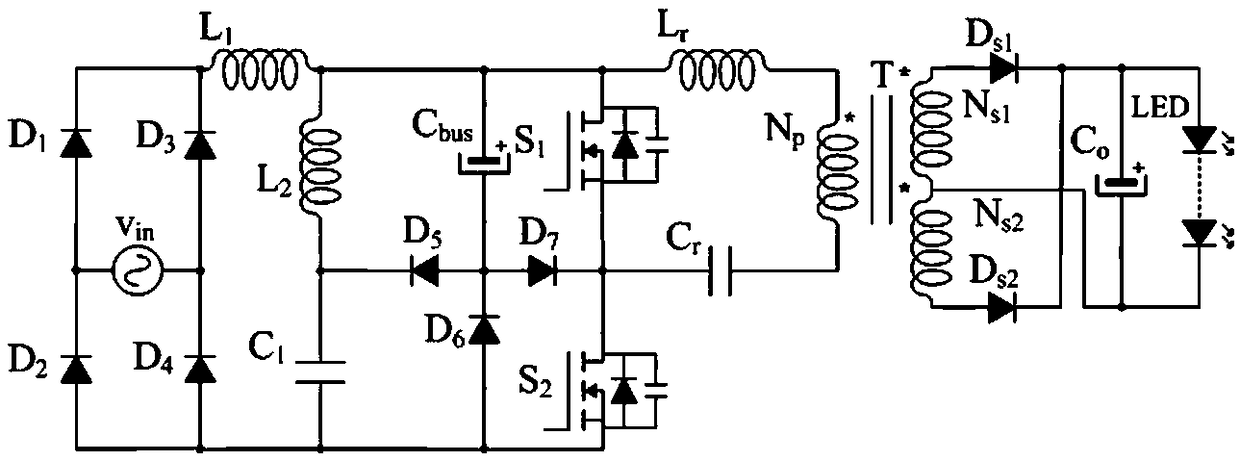

[0051] Such as figure 1 As shown, this embodiment provides a single-stage LED drive circuit integrating step-down Cuk and LLC converter, including a single-phase AC input power supply v in , the first power diode D 1 , the second power diode D 2 , the third power diode D 3 , the fourth power diode D 4 , the fifth power diode D 5 , the sixth power diode D 6 , the seventh power diode D 7 , the eighth power diode D s1 , the ninth power diode D s2 , the first power switch tube S 1 , the second power switch tube S 2 , High frequency capacitor C 1 , Bus capacitance C bus , output capacitance C o , Resonant capacitance C r , Cuk inductance L 1 , Cuk inductance L 2 , Resonant inductance L r , High frequency transformer T, LED light load.

[0052] The first power diode D 1 The cathode of the third power diode D 3 The cathode an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com