Pump pushing device used for ship

A technology for ships and hulls, which is applied in the field of pump propulsion devices for ships. It can solve the problems that the propeller speed should not be too high, the radius of gyration is not flexible enough, and the navigation area of ships is limited, so as to improve flexibility and maneuverability, sensitive steering, The effect of expanding the driving area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

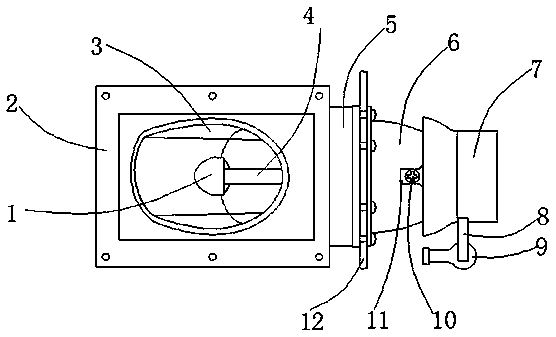

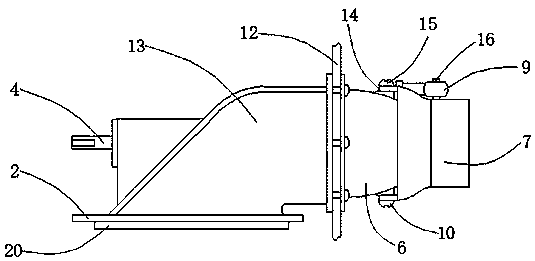

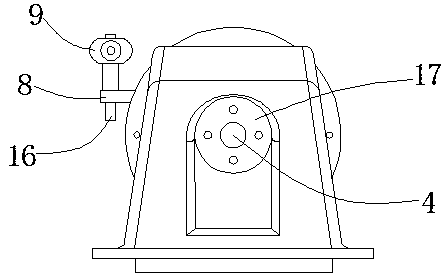

[0021] The present invention will be further described below in conjunction with accompanying drawing:

[0022] Such as Figure 1-Figure 5 As shown, a pumping device for a ship includes a bottom plate 2, a hull 12, a rectifying body 6, and a steering conduit 7. A gasket 20 is provided on the lower surface of the bottom plate 2, a water suction port 3 is provided in the middle of the bottom plate 2, and a water inlet 3 is provided on the upper surface of the bottom plate 2. There is a housing 13, a shaft sleeve 1 is arranged on one side of the housing 13, a rotating shaft 4 is arranged inside the shaft sleeve 1, an impeller 18 is arranged at one end of the rotating shaft 4, and a shaft is arranged on the side of the shaft sleeve 1 away from the housing 13. Sealing 17, the casing 13 is provided with a water inlet pipe 5 on the side away from the shaft casing 1, the side of the water inlet pipe 5 away from the casing 13 is provided with a hull 12, and the side of the hull 12 away...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com