Production method for antibacterial agent potassium hexadienoic acid

A kind of technology of potassium hexadienoate and production method, which is applied in the production field of antibacterial agent potassium hexadienoate, and can solve problems such as complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0005] The production method of the antibacterial agent potassium hexadienoate, the main steps are: add sorbic acid in the reaction kettle, then add water that is 75% of the weight of sorbic acid, and dropwise add a potassium hydroxide solution with a mass fraction of 30% at 55°C until the reaction Solution pH=8.3, react for 70min. Add a certain amount of activated carbon, vacuum filter, and distill the filtrate under reduced pressure at 50°C for 1h, then raise the temperature to 60°C and discharge. Crystallization was obtained by centrifugal dehydration, the mother liquor was recovered, and finally dried at 115°C for 2 hours to obtain the product.

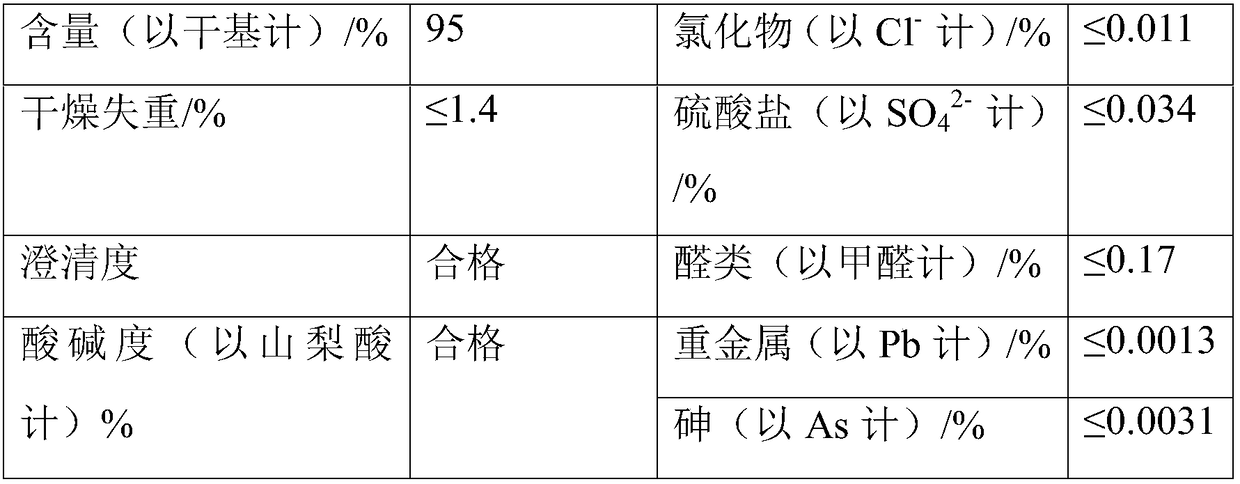

[0006] product quality

[0007]

example 2

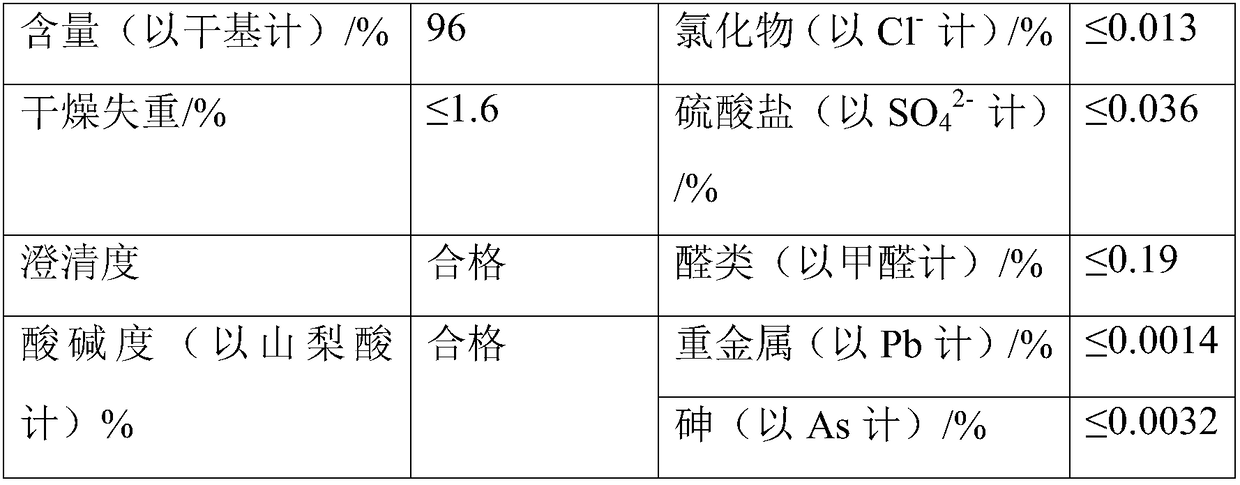

[0009] The production method of the antibacterial agent potassium hexadienoate, the main steps are: add sorbic acid in the reaction kettle, then add water that is 80% of the weight of sorbic acid, and add dropwise a potassium hydroxide solution with a mass fraction of 36% at 60°C until the reaction Solution pH=8.6, react for 90min. Add a certain amount of activated carbon, vacuum filter, and distill the filtrate under reduced pressure at 56°C for 2h, then raise the temperature to 64°C and discharge. Crystallization was obtained by centrifugal dehydration, the mother liquor was recovered, and finally dried at 120°C for 3 hours to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com