Steel ladle bottom argon blowing gas flow control device and control method

A technology of argon flow and bottom blowing argon, which is applied in the direction of flow control, flow control using electrical devices, non-electric variable control, etc., can solve the problem that the flow rate of argon gas flow at the bottom of the ladle cannot be automatically and accurately controlled, and reduce manual labor. Strength, improved molten steel quality, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

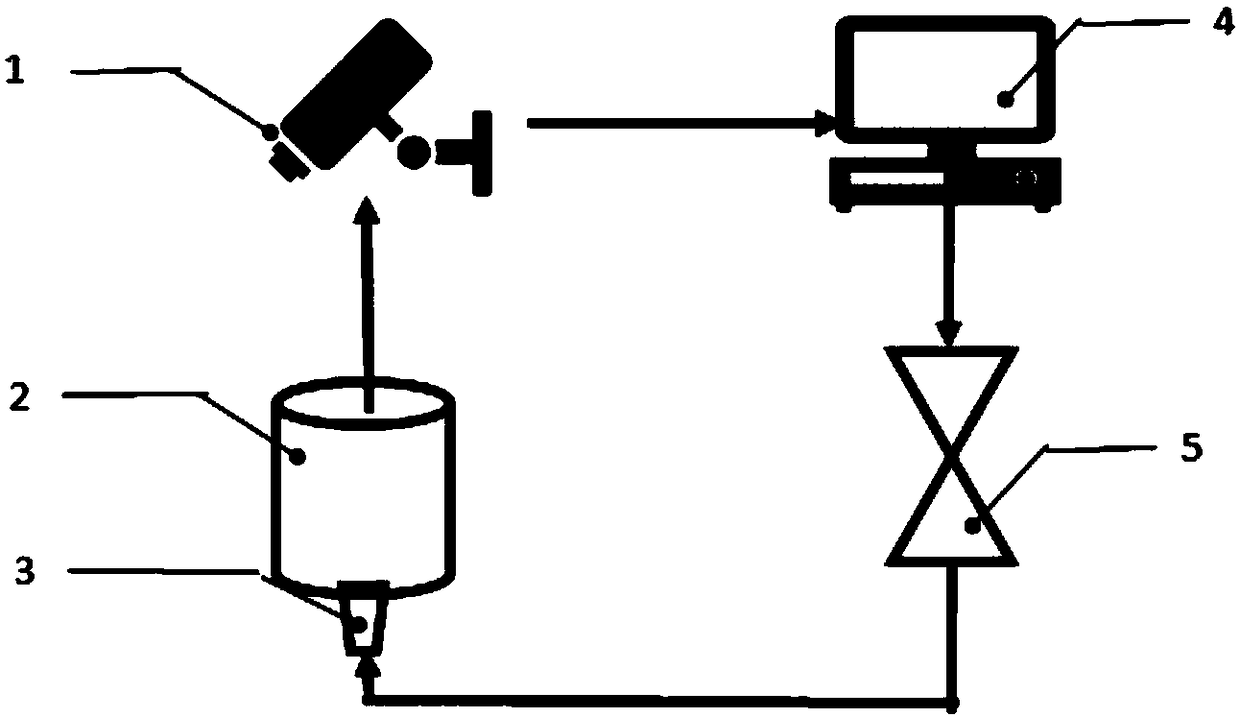

[0020] Embodiment 1, the method for controlling the flow rate of argon blowing at the bottom of the ladle with the above-mentioned device comprises the following steps:

[0021] 1) The image processing and control center server 4 has a database including argon gas flow valve opening, argon gas flow range, ladle bottom argon blowing intensity and molten steel exposure ratio corresponding table, and the image processing and control center server has a ladle Argon blowing strong stirring or weak stirring corresponds to the ratio standard of the exposed surface of molten steel to the molten steel surface: strong stirring means that the exposed area of molten steel accounts for 26-75% of the molten steel surface; weak stirring refers to the ratio of the exposed area of molten steel to the liquid surface of molten steel. 5-25%; violent blowing means that the exposed area of molten steel accounts for more than 75% of the molten steel surface, and violent blowing is not allowed d...

Embodiment 2

[0027] Embodiment 2, the method for controlling the flow rate of argon blowing at the bottom of the ladle with the above-mentioned device, comprising the following steps:

[0028]1) The image processing and control center server 4 has a database including argon gas flow valve opening, argon gas flow range, ladle bottom argon blowing intensity and molten steel exposure ratio corresponding table, and the image processing and control center server has a ladle Argon blowing strong stirring or weak stirring corresponds to the ratio of the exposed surface of molten steel to the molten steel surface: strong stirring means that the exposed area of molten steel accounts for 26-75% of the molten steel surface; weak stirring refers to the ratio of the exposed area of molten steel to the liquid surface of molten steel. 5-25%; violent blowing means that the exposed area of molten steel accounts for more than 75% of the molten steel surface, and violent blowing is not allowed during op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com