A method for smelting ultra-low carbon steel and a method for continuously casting ultra-low carbon steel

A technology of ultra-low carbon steel and molten steel, applied in the field of smelting ultra-low carbon steel, can solve the problems of restricting the production of ultra-low carbon steel and the development of varieties, low comprehensive pass rate, unfavorable mass production of ultra-low carbon steel, etc., to achieve The effect of reducing the consumption of deoxidizer aluminum, improving the quality of molten steel, and improving the cleanliness of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment is used to illustrate the production method of the low carbon steel provided by the present invention.

[0047] The molten iron with a sulfur content of less than 0.015% by weight is initially smelted using a converter. During compound blowing, the top-blown pure oxygen is 28,000 standard cubic meters per hour, and the bottom-blown pure argon has an intensity of 0.035Nm. 3 / ton of molten steel min, blowing argon gas at the bottom for 6 minutes after tapping, and the strength is 0.2Nm 3 / ton of molten steel min, to carry out intensive stirring before tapping; the carbon content at the blowing end point is 0.06% by weight, the oxygen activity content of molten steel is 400ppm, and the temperature of tapping molten steel is 1670°C;

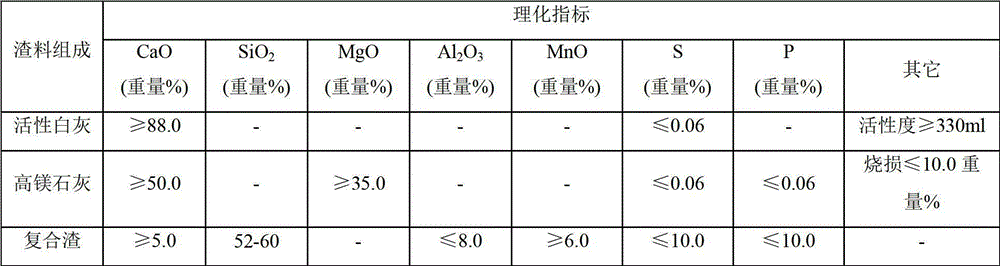

[0048] After the steel converter is smelted, the alkalinity (CaO / SiO 2 The molten steel slag material (refining slag adjusting agent) with a weight ratio) of 4-5 is mixed with molten steel, and the addition amount is 1.5 kg / ...

Embodiment 2

[0061] This embodiment is used to illustrate the production method of the low carbon steel provided by the present invention.

[0062] The molten iron with a sulfur content of less than 0.015% by weight is initially smelted using a converter. During compound blowing, the top-blown pure oxygen is 28,000 standard cubic meters per hour, and the bottom-blown pure argon has an intensity of 0.035Nm. 3 / ton of molten steel min, blowing argon gas at the bottom for 6 minutes after tapping, and the strength is 0.2Nm 3 / ton of molten steel min, to carry out intensive stirring before tapping; the carbon content at the blowing end point is 0.05% by weight, the oxygen activity content of molten steel is 450ppm, and the temperature of tapping molten steel is 1670°C;

[0063] After the steel converter is smelted, the alkalinity (CaO / SiO 2 Weight ratio) of 4-5 slag (molten steel refining slag adjustment agent), mixed with molten steel, the addition amount is 1.5 kg / ton molten steel, the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com