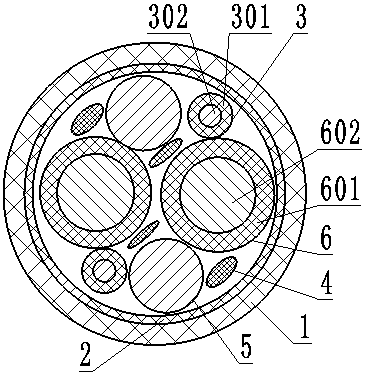

Mooring optical cable capable of keeping power on under condition of drawing

A power-cutting and tethering technology, applied in the direction of extensible conductor cables, communication cables, cables, etc., can solve the problems of small cross-sectional area of electrical units, large outer diameter of composite cables, and power limitations, and achieve functional satisfaction and anti-corrosion The effect of high tensile strength and small outer diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The composition of the nanofluid is: 50 parts by weight of nano-carbon powder, 50 parts by weight of nano-copper powder, 70 parts by weight of flake graphite powder, 30 parts by weight of nano-bismuth alloy, and the powder particle size of nano-carbon powder is 120 nm to 300 nm. The particle size of the nano copper powder is 20 to 100 nanometers, and the particle size of the nano bismuth alloy powder is 100 to 300 nanometers.

Embodiment 2

[0020] The composition of the nanofluid is: 30 parts by weight of nano-carbon powder, 60 parts by weight of nano-copper powder, 60 parts by weight of flake graphite powder, 30 parts by weight of nano-bismuth alloy, and the powder particle size of nano-carbon powder is 120 nm to 300 nm. The particle size of the nano copper powder is 20 to 100 nanometers, and the particle size of the nano bismuth alloy powder is 100 to 300 nanometers.

Embodiment 3

[0022] The composition of the nanofluid is: 30 parts by weight of nano-carbon powder, 60 parts by weight of nano-copper powder, 60 parts by weight of flake graphite powder, and 10 parts by weight of nano-bismuth alloy. The powder particle size of nano-carbon powder is 120 nm to 300 nm. The particle size of the nano copper powder is 20 to 100 nanometers, and the particle size of the nano bismuth alloy powder is 100 to 300 nanometers.

[0023] The principle and advantages of the present invention: The difference from the previous photoelectric composite cable is that the power supply of the photoelectric composite cable used before is limited, the cross-sectional area of the electrical unit is small, and the outer diameter is relatively large. The previous photoelectric composite cable laying method is overhead, through pipe Fixed places such as ground, buried, etc., are commonly used optical cable laying and installation methods. In devices and equipment that can be used, these t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com