Electrolyte and secondary battery

A technology of electrolyte and electrolyte salt, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of secondary battery cycle performance, high temperature storage performance, safety performance, and poor rate performance, and achieve the effect of improving rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] (4) Preparation of separator

[0064] A 16 μm thick polypropylene isolation film (model C210, provided by Celgard) was selected.

[0065] (5) Preparation of lithium-ion secondary battery

[0066] Stack the positive electrode, separator, and negative electrode in order, so that the separator is between the positive and negative electrodes to play a role of isolation, and then wind up to get the bare cell; put the bare cell in the outer packaging foil, and the battery After the core was left standing at a high temperature of 75°C for 24 hours, after the water content met the specifications, the above-mentioned prepared electrolyte was injected into the dried bare cell, and after vacuum packaging, standing, chemical formation, shaping and other processes, the lithium-ion secondary cell was obtained. secondary battery.

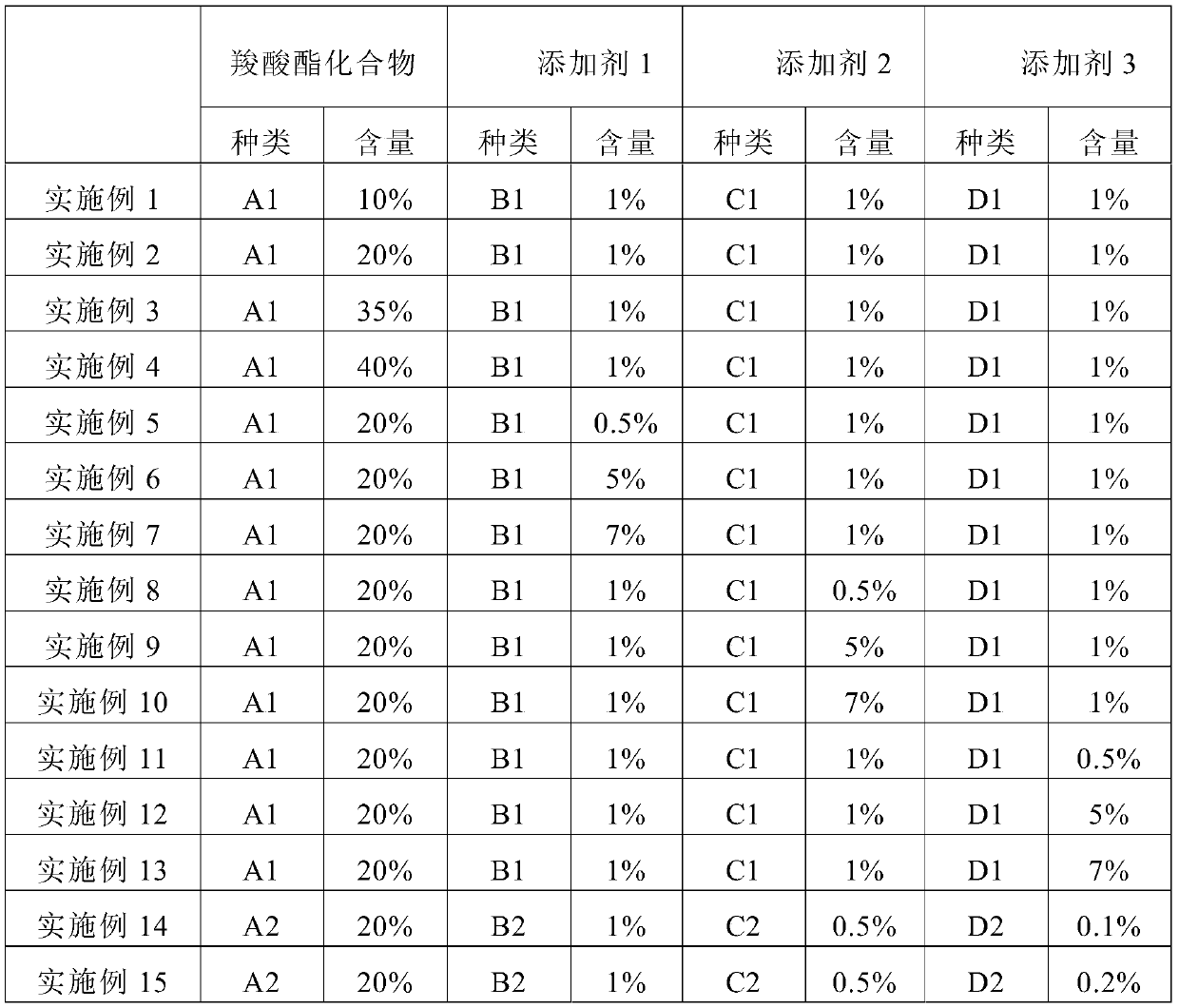

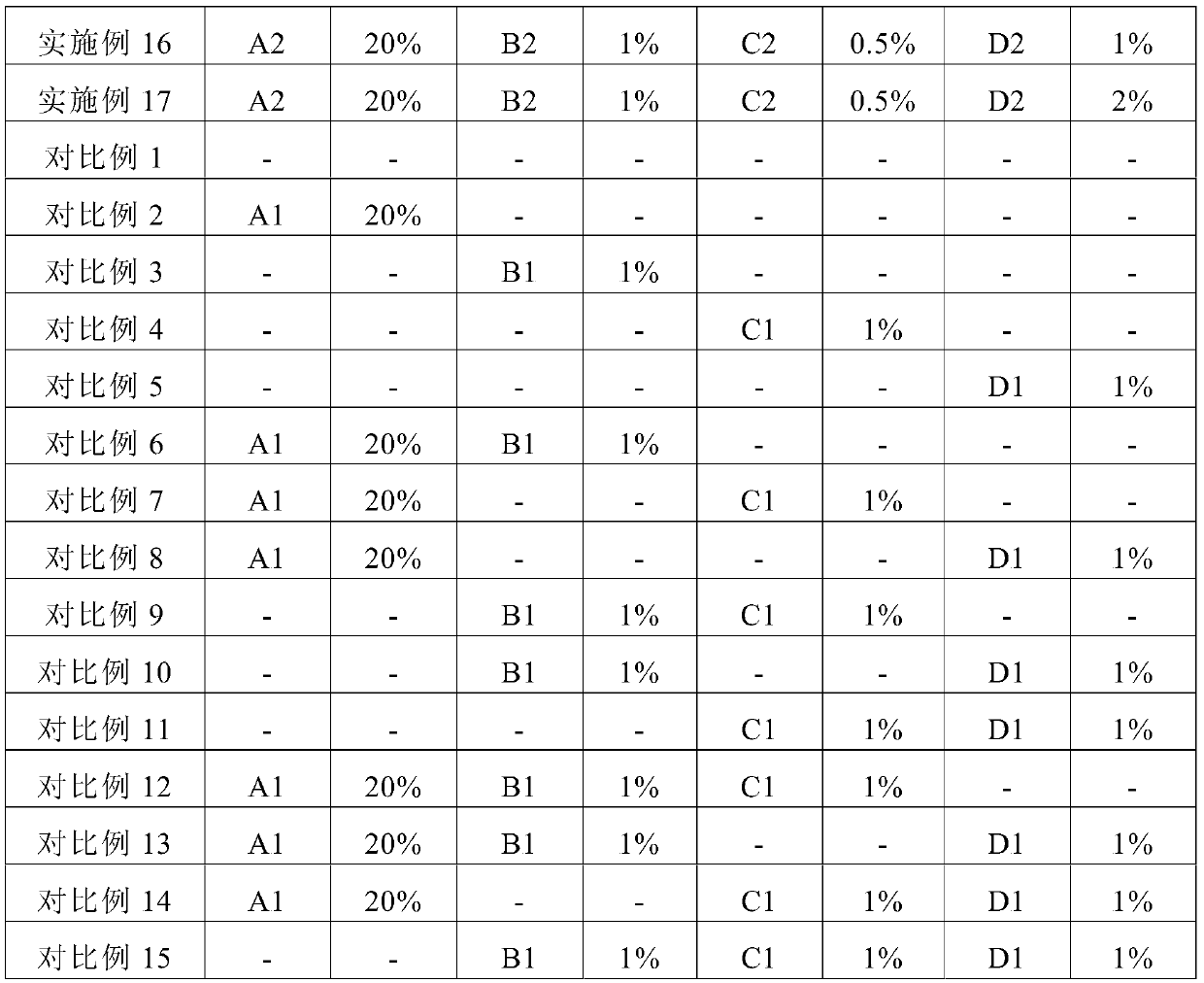

[0067] Table 1 The parameters of Examples 1-17 and Comparative Examples 1-15

[0068]

[0069]

[0070] Note: "-" means not included.

[0071] Ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com