Twin-axial cable with novel structure and method for testing intra-pair transmission skew

A technology of parallel double conductors and a new structure, applied in the direction of applying a stable bending force to test the strength of the material, applying a repetitive force/pulse force to test the strength of the material, waveguide, etc. Line pair differential impedance deviation, dielectric constant difference and other issues, to achieve the effect of simplifying the on-site installation process, small delay difference between pairs, and low impedance attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

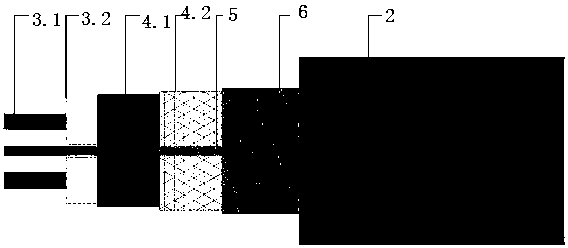

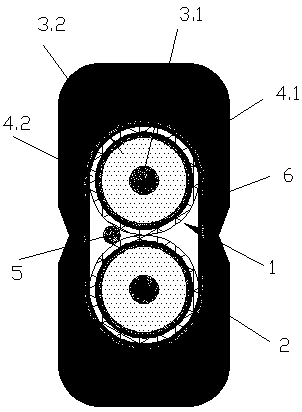

[0033] Embodiment 1: as figure 1 , figure 2 Shown: a parallel twin-conductor cable with a new structure, including a wire pair 1 and a sheath layer 2. The wire pair 1 includes two conductive core wires 3, and the conductive core wire 3 includes an inner conductor 3.1 and an insulating layer outside the inner conductor 3.1 3.2, each conductor core wire 3 is provided with a shielding layer outside the insulating layer 3.2. The shielding layer includes inner and outer shielding layers (4.1, 4.2). The inner shielding layer 4.1 is a metal composite tape composed of polyester (PET) inside and metal copper foil outside. The outer shielding layer 4.2 is a wire braided layer. The metal composite tape of the inner shielding layer 4.1 is spirally wrapped or longitudinally wrapped on a single conductive core wire, the overlapping rate of the metal composite tape wrapping is not less than 40% or the overlapping rate of the longitudinal wrapping is not less than 15%, and the outer shield...

Embodiment 2

[0034] Embodiment 2: Referring to Embodiment 1, a drain line 5 is provided in the gap between the wire pairs 1, and a wire pair shield 6 is provided outside the wires, and the setting is cancelled.

[0035] The wire is longitudinally wrapped with a layer of single-sided metal composite tape, with the metal facing inward, and the overlap rate of the longitudinal wrap is not less than 25%; The composite foil metal faces outward, and the outer metal composite foil metal faces inward. The overlapping rate of each layer of wrapping is not less than 20%, which can be completed on one piece of equipment.

[0036] The so-called longitudinal wrapping or lapping ratio here refers to the ratio of the overlapping width of the metal composite tape to its total width, and its definition is the test method, and the definition of the weaving density is the test method are well known in the industry.

[0037] Two insulated core wires with separate shielding can be directly extruded with a figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com