A UHV double-shielded composite bushing

A composite sleeve and double-shielding technology, applied in the direction of magnetic/electric field shielding, modification through conduction heat transfer, insulators, etc., can solve the problems of uneven internal electric field distribution, poor local heat dissipation performance, and reduced equipment reliability, etc., to achieve Avoid partial discharge, enhance heat dissipation, and reduce radio interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

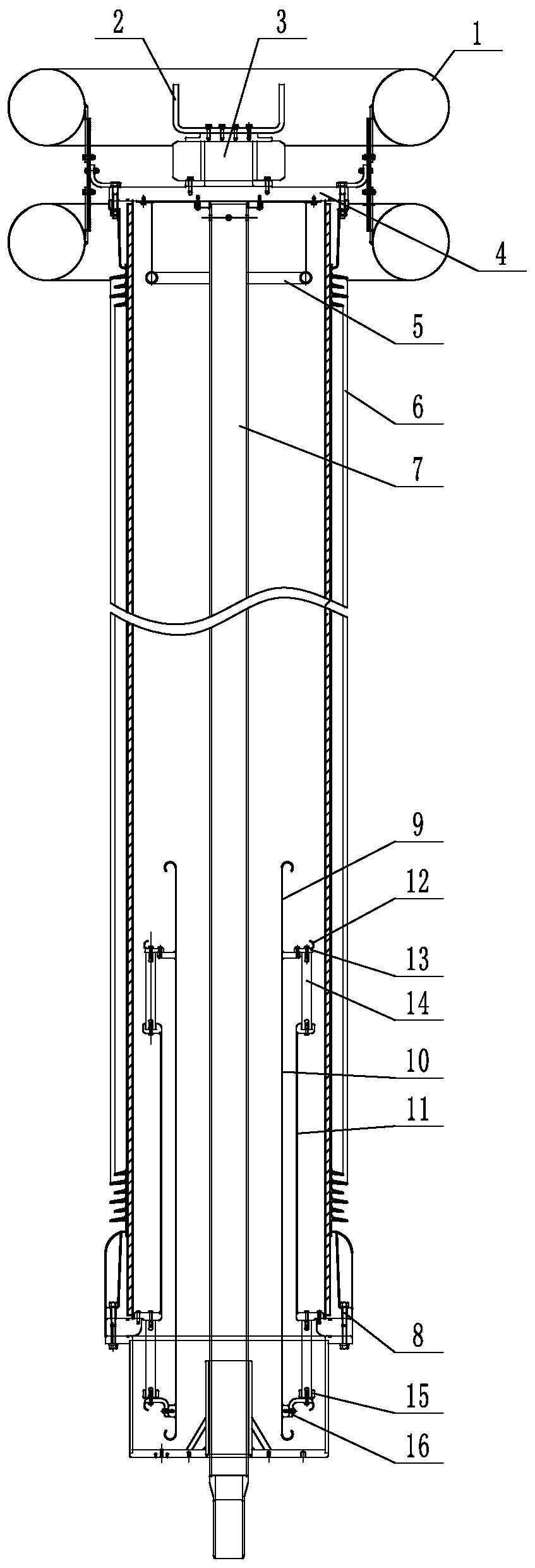

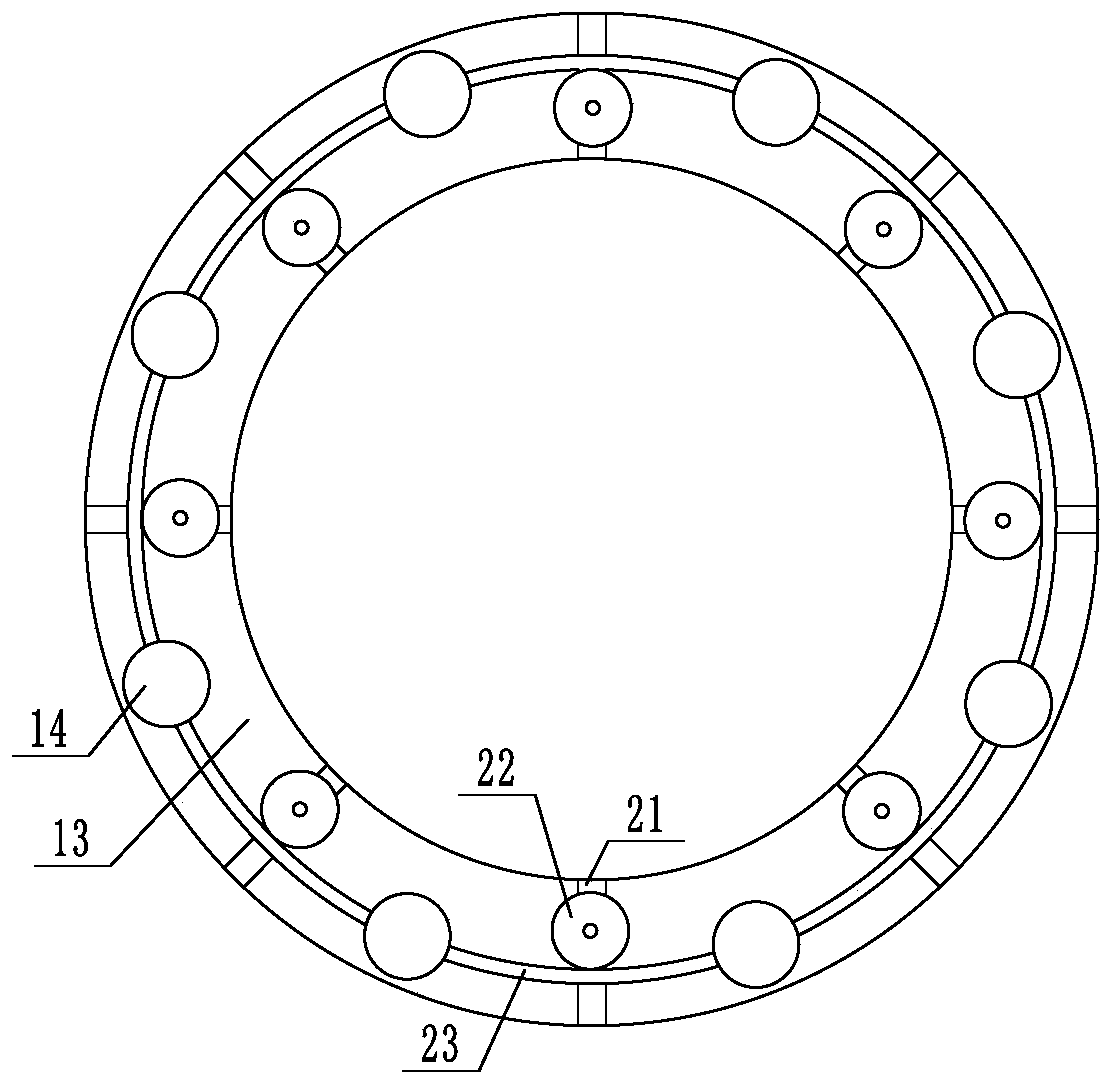

[0027] Such as Figure 1 to Figure 3 As shown, a UHV double-shielded composite bushing includes an intermediate conductor 7, an insulating sleeve 6 is sleeved on the outside of the intermediate conductor, and the insulating sleeve 6 and the end cover 4 are connected by bolts. The intermediate conductor 7 and the The end caps 4 are connected by bolts. The insulating sleeve 6 is connected with the transition flange 8 by bolts. An upper shield 5 is also provided on one side of the intermediate conductor 7, and the upper shield 5 is fixedly connected to the end cover 4 by bolts.

[0028] The end cover 4 and the double shielding ring 1 are connected by bolts, and the terminal 2 is provided on the end cover 4, in order to avoid the high local temperature caused by the poor heat dissipation at the terminal, which will lead to changes in the electric field and cause safety hazards.

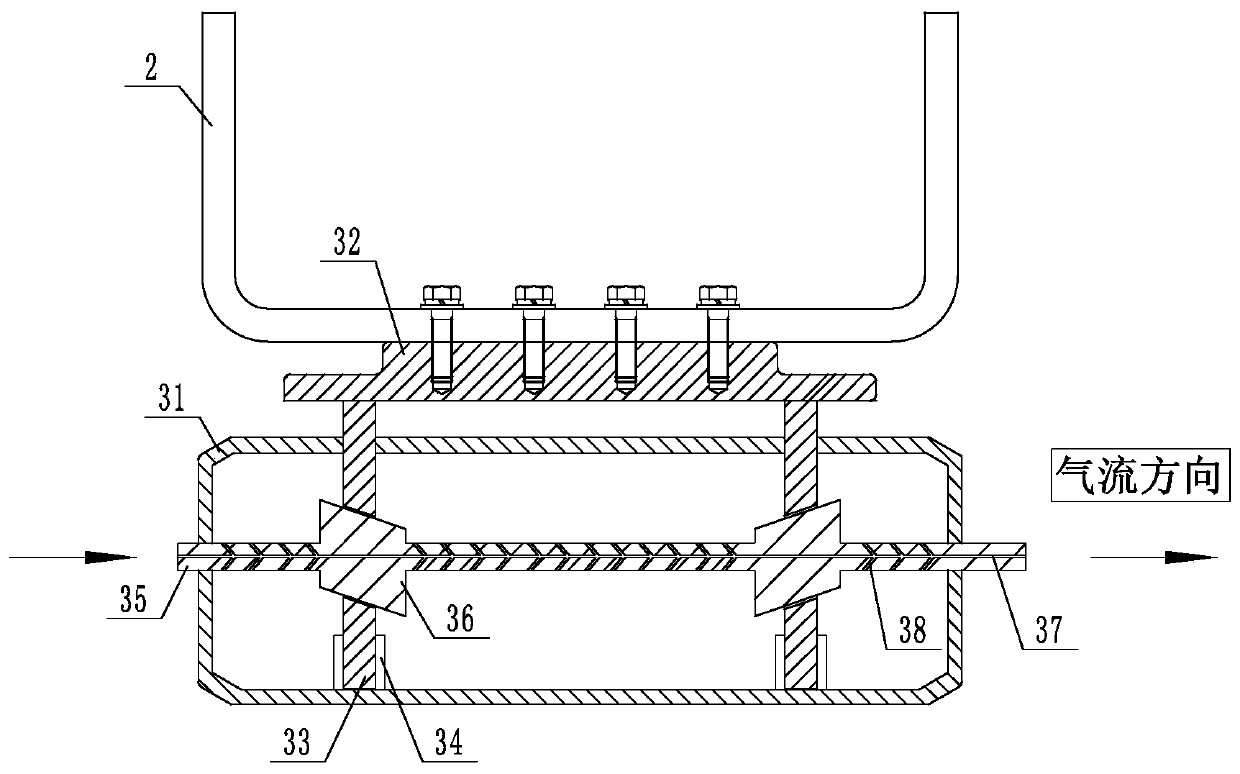

[0029] A heat dissipation adjustment mechanism 3 is provided between the end cover and the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com