Tool equipment and method for hydraulic motor front end cover two-way lip seal assembly

A technology for sealing components and hydraulic motors, applied in mechanical equipment, engine sealing, manufacturing tools, etc., can solve the problems of demolition destructive, lip failure, O-ring crushing of sealing components, etc., and achieve fast and convenient installation and removal. , Improve the service life, the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0039] In the present invention, in the absence of description, the used orientation words such as "up and down" are respectively the directions indicated by the up and down arrows in the figure.

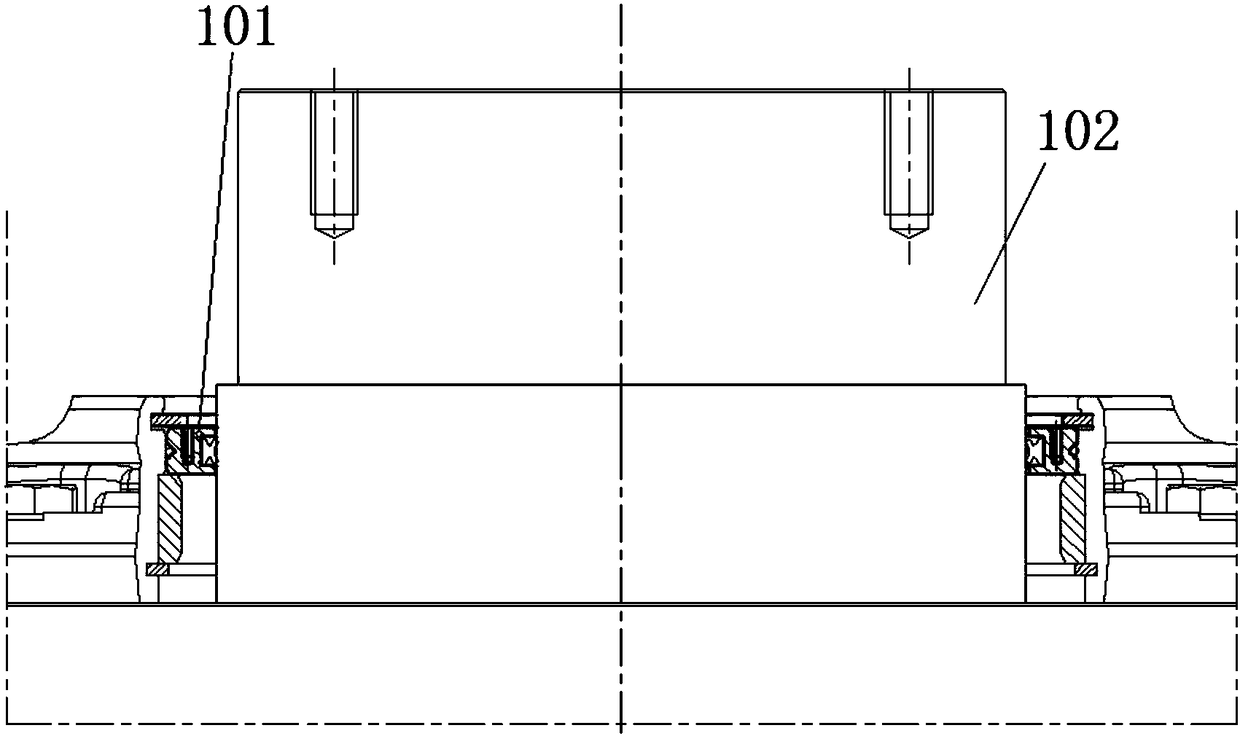

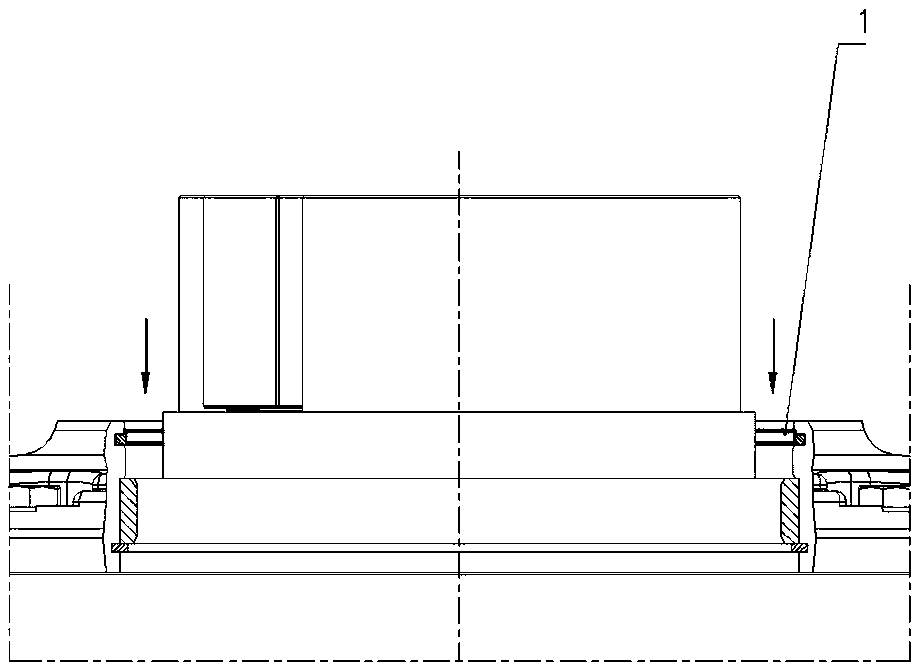

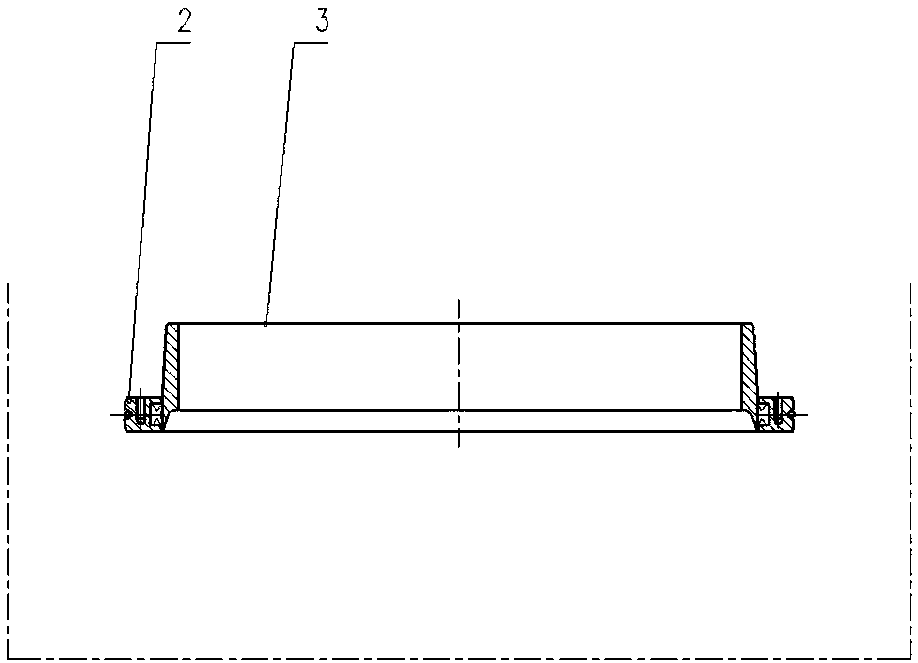

[0040] see Figure 2A -H and Figure 3A -C, shows the tooling equipment and method of the double-way lip seal assembly of the hydraulic motor front end cover of the present invention.

[0041]The tooling equipment of the two-way lip seal assembly of the front cover of the hydraulic motor may include an open plastic ring 1, a guide collar 3, a first flange 4, a mounting bolt 5, a long screw rod 6, a nut 7, a second flange 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com