Bus-based direct-current motor and control method thereof

A technology of DC motor and control method, which is applied in the direction of DC motor speed/torque control, computer control, program control, etc., can solve the problems of complicated motor wiring, complicated wiring and high cost, and achieves a high degree of integration, simple control, and high cost. Set up convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make it easy to understand the technical means, creative features, achieved goals and effects of the present invention, the present invention is further described below.

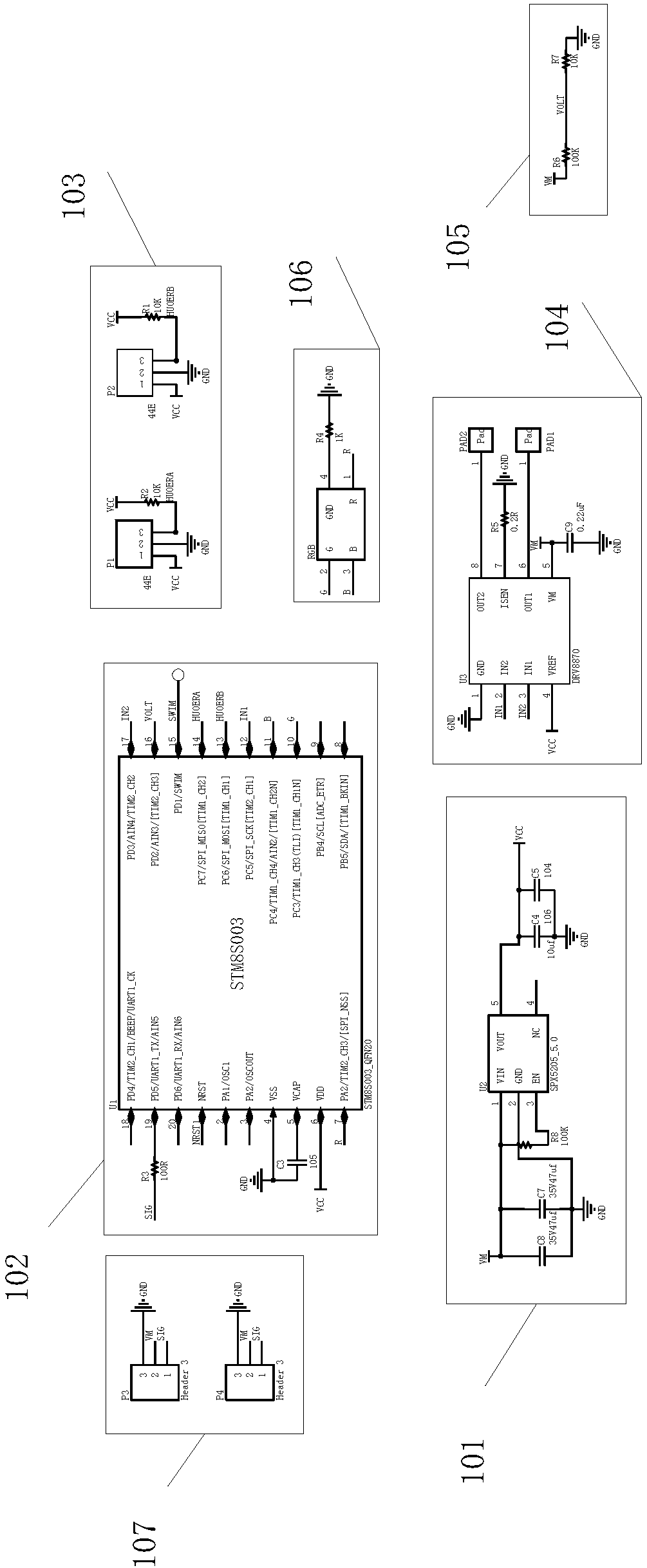

[0044] like figure 1 System schematic shown:

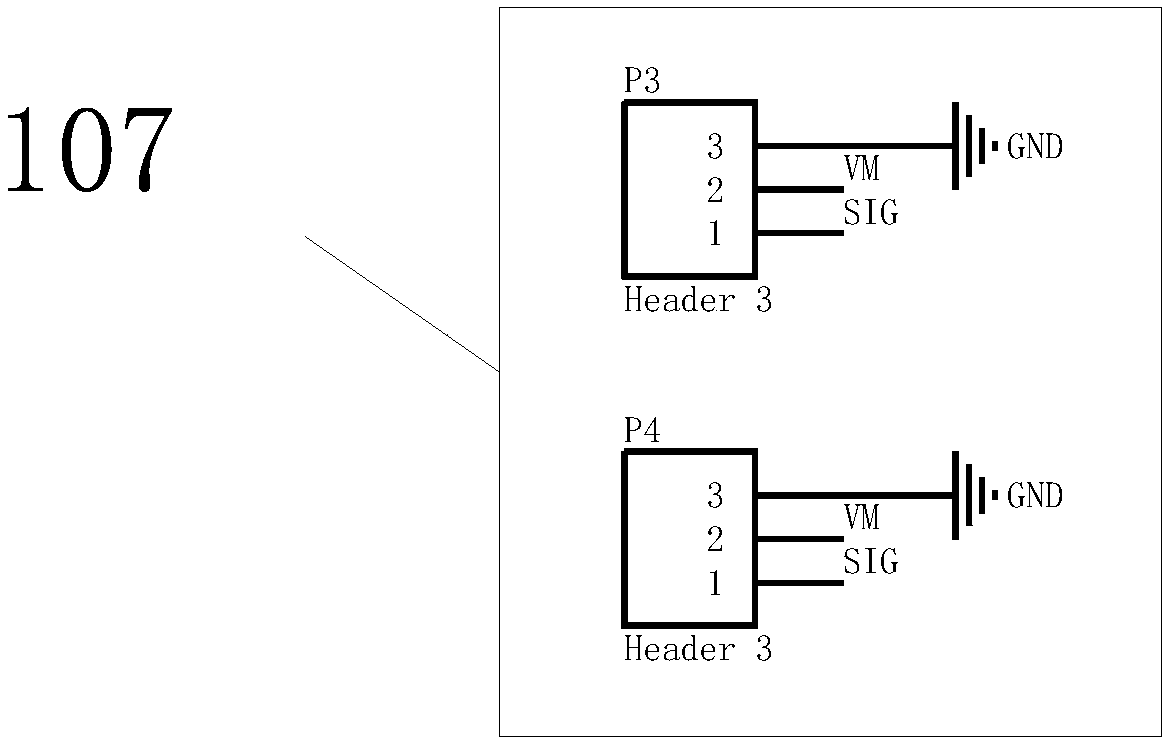

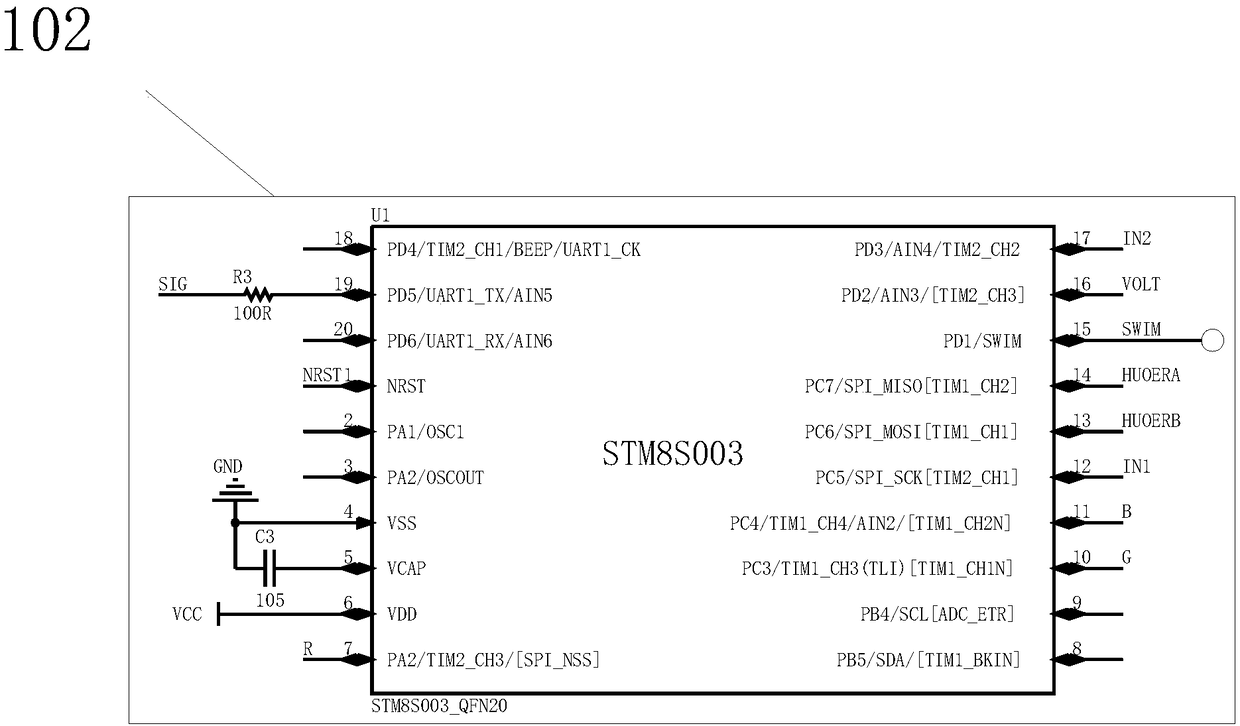

[0045] A bus-type DC motor, including a power supply module 101 for power supply, the power supply module 101 is connected with a main control module 102, an encoder module 103, and a motor drive module 104 to supply logic power and power power, wherein the logic power is an input voltage The 3.3V or 5V power supply obtained after voltage reduction, the power supply is used to input power to the motor chip of the motor drive module 104, and the main control module 102 is connected to the motor drive module 104 for controlling the motor. The module 102 is connected with the encoder module 103 for measuring speed and position, the main control module 102 is connected with a voltage detection module 105 for voltage detection, and the main contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com