Method for predicting thermal mechanical fatigue life of metal material based on low cycle fatigue

A thermo-mechanical fatigue and low-cycle fatigue technology, applied in computer-aided design, special data processing applications, instruments, etc., can solve the problems of large experimental volume, low accuracy, high time, labor, and money costs, and achieve a clear physical meaning. , good applicability, good universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

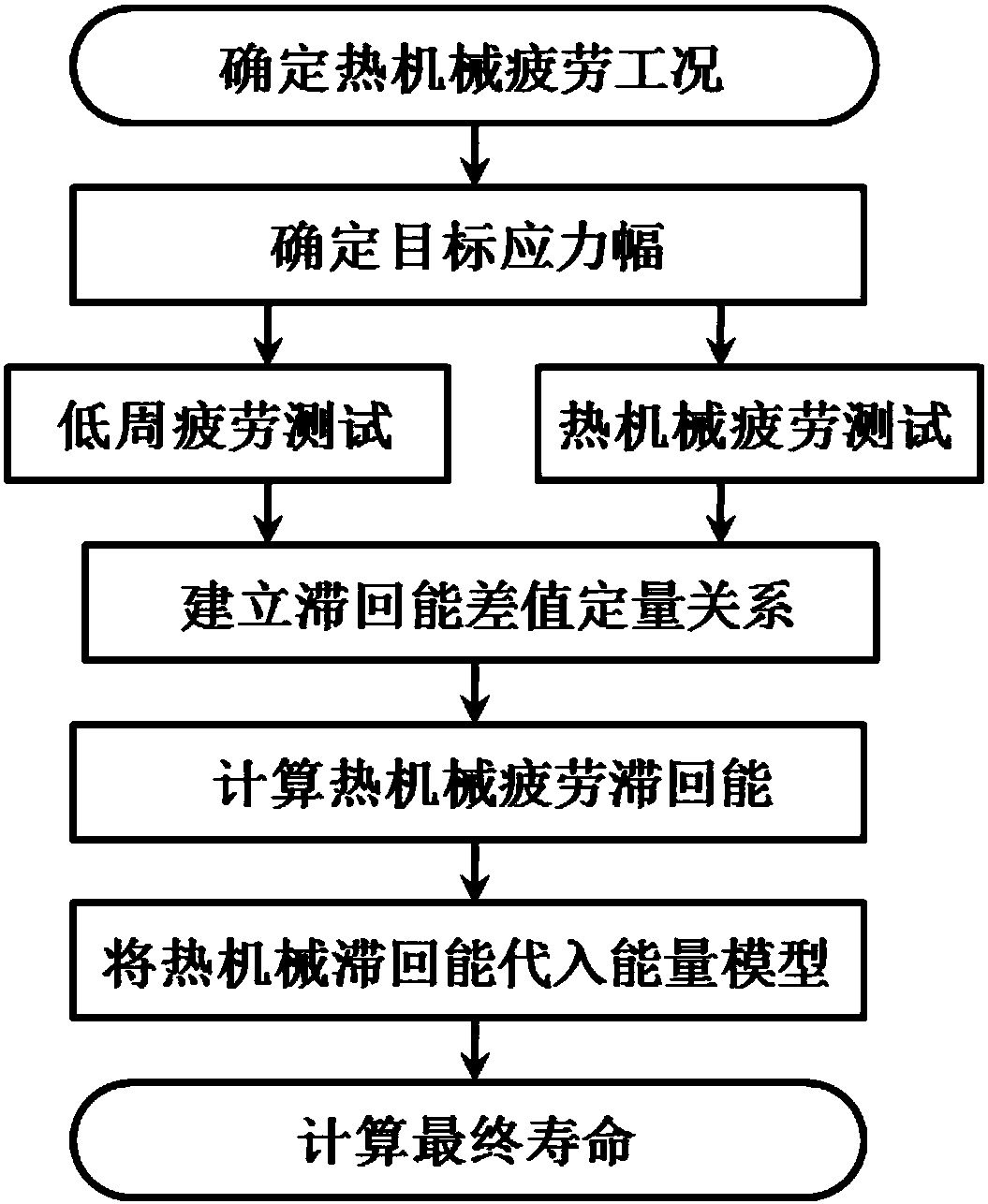

[0034] This embodiment is to predict the life of cast iron materials under the reverse potential thermomechanical fatigue condition. The prediction process is as follows figure 1 As shown, the specific process is as follows:

[0035] First, the cast iron material is taken from the diesel engine cylinder head. According to the working conditions, it is determined that the required predicted thermomechanical fatigue temperature load is 125-400°C and 125-500°C, and the mechanical strain condition is ±0.1%-±0.4%.

[0036] Second, in this embodiment, for the working condition of 125-400°C, the target strain amplitude is ±0.15%, ±0.2%, ±0.3%; for the working condition of 125-500°C, the target strain amplitude Values are ±0.15%, ±0.2%, ±0.3%. Here, multiple strain amplitudes are selected as the target strain amplitudes, the purpose of which is to compare with the experimental results.

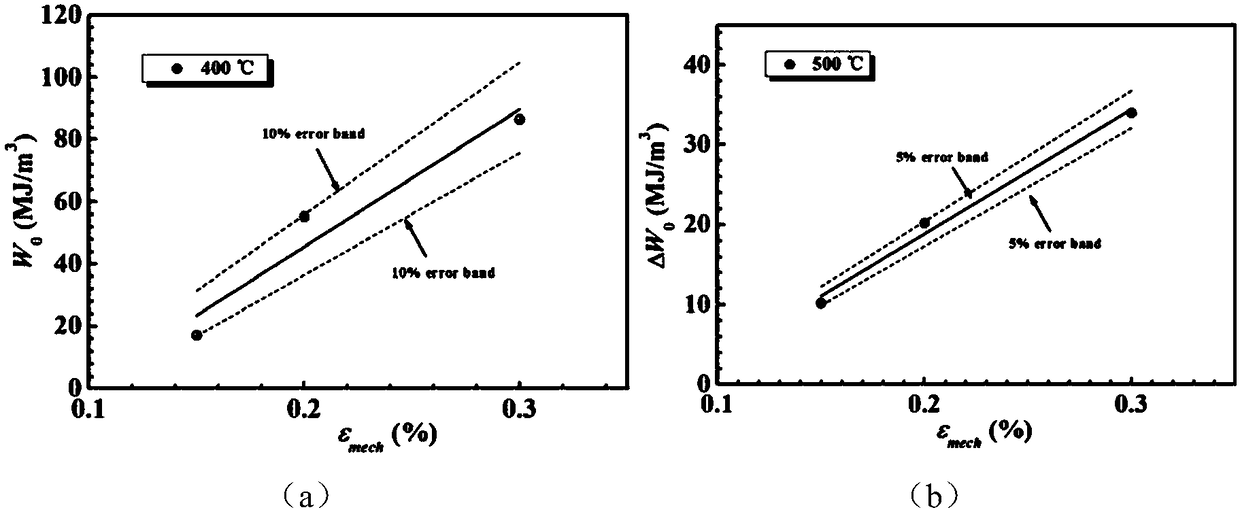

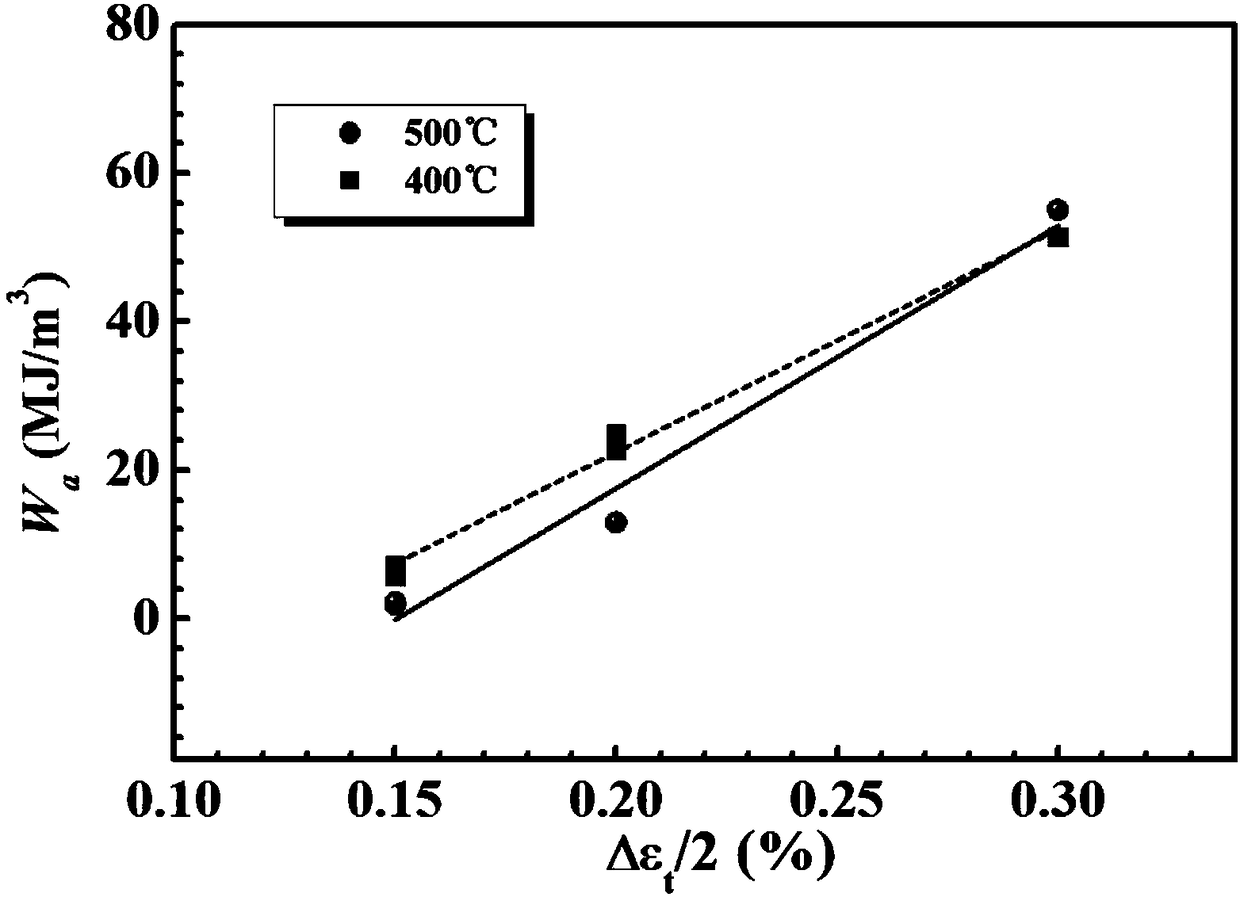

[0037]Third, the low cycle fatigue test, the test conditions are: three tests at 400°C, with m...

Embodiment 2

[0053] This embodiment is to predict the life of the cast aluminum material under the condition of thermomechanical fatigue in the same direction.

[0054] First, the cast aluminum material is taken from the diesel engine piston. According to the working conditions, it is determined that the required predicted thermomechanical fatigue temperature load is 125-350°C, and the mechanical strain condition is ±0.1%-±0.4%.

[0055] Second, in this embodiment, for the temperature load of 125 to 350°C working conditions, the target strain amplitudes are ±0.25%, ±0.35%, ±0.3%, ±0.45%; multiple strain amplitudes are selected here , as the target strain amplitude, the purpose of which is to compare with the experimental results.

[0056] Third, the low cycle fatigue test, the test conditions are: four tests at 350°C, the mechanical strains are ±0.25%, ±0.35%, ±0.3%, ±0.45% respectively; calculate the median life hysteresis loop area of each test data .

[0057] Fourth, thermomechanica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com