An optimal design method for water-lubricated thrust bearings with tilting pads made of resin-based composite materials for nuclear main pumps

A technology of thrust bearings and composite materials, applied in computer-aided design, calculation, instruments, etc., can solve problems such as difficult to solve the simulation interface slip elastohydrodynamic lubrication model, two-dimensional elastohydrodynamic lubrication model calculation difficulty, large amount of calculation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings.

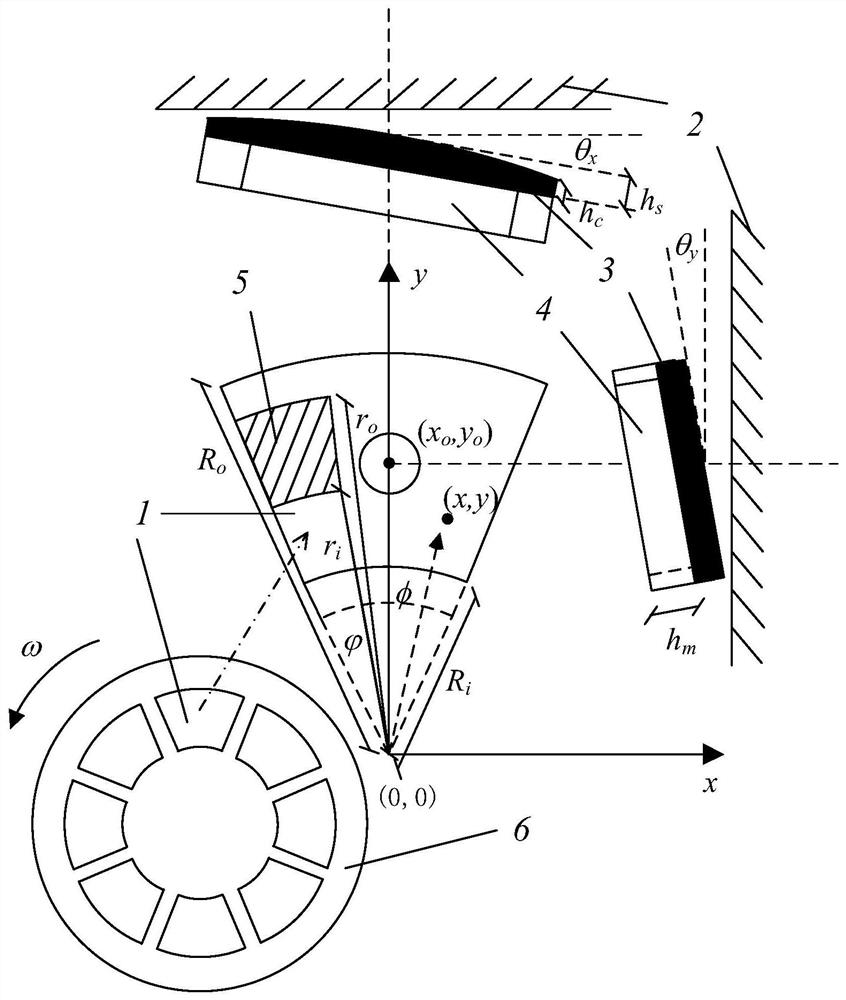

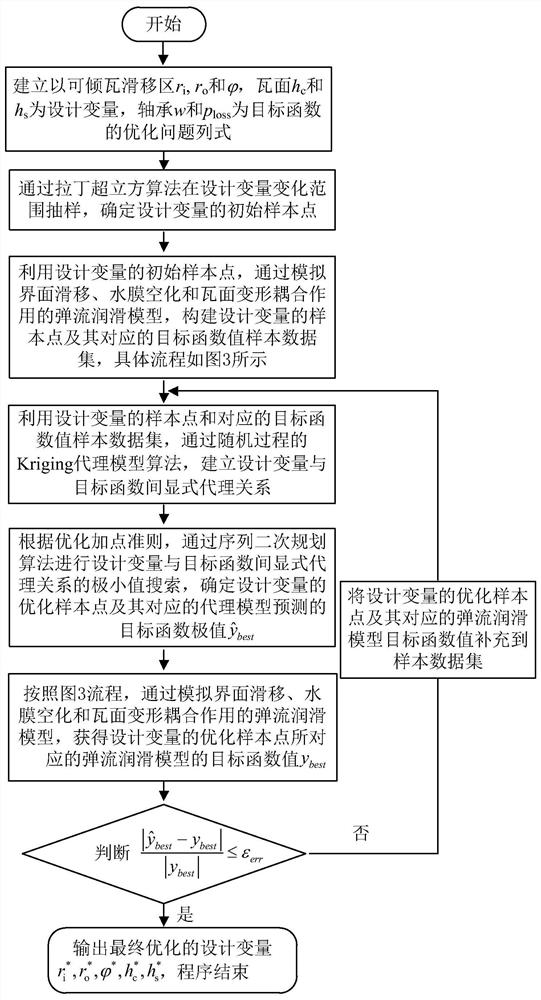

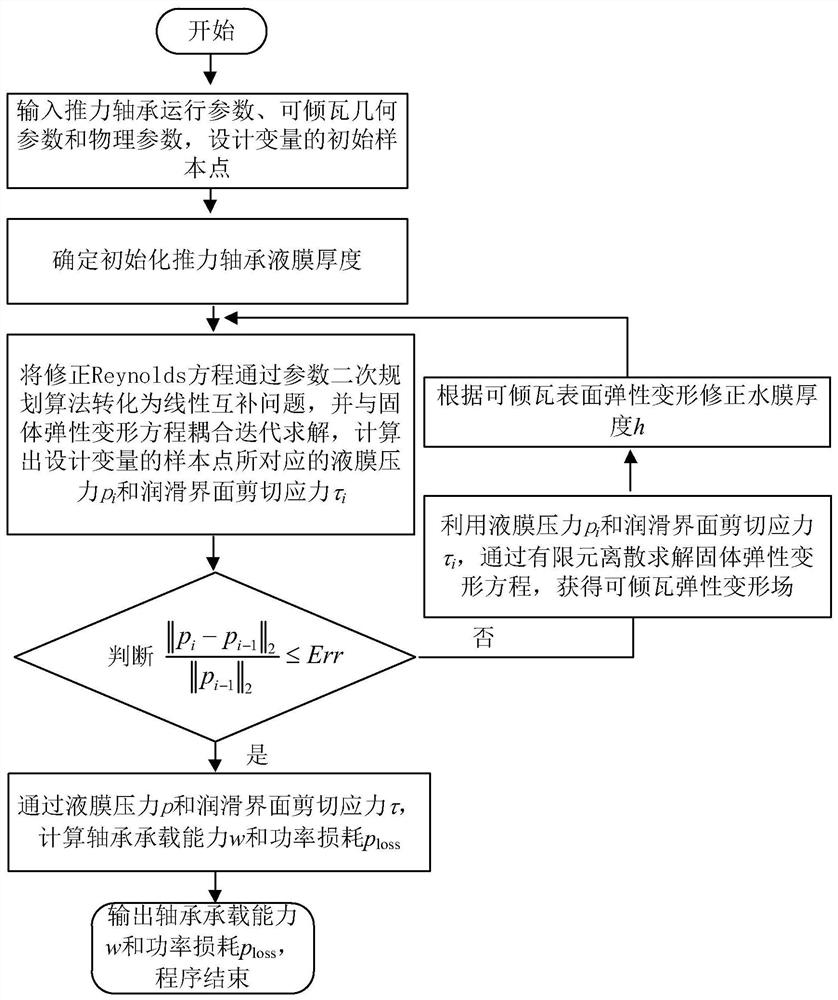

[0044] figure 1 It is a schematic diagram of the tilting pad structure of the resin-based composite material tilting pad water-lubricated thrust bearing of the nuclear main pump of the present invention. As shown in the figure, the metal material thrust plate 2 of the tilting pad water-lubricated thrust bearing rotates at ω, and the tilting pad 1 and the tilting pad support mechanism 6 do not rotate. n, the temperature T and viscosity η of the bearing water, the coordinates of the tilting pad support center (x o ,y o ), tilt angle θ x , θ y , the water film thickness h in the support center r , the boundary pressure P of the water film on the tilting tile b ;Geometric parameter of tilting pad: inner diameter R i , outer diameter R o , wrap angle φ, tile thickness h m , the maximum thickness h of cylindrical resin-based composite mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com