Speed sensorless control method of permanent magnet synchronous linear motor

A permanent magnet synchronous linear, speed sensorless technology, used in motor control, single motor speed/torque control, motor generator control, etc., can solve the problems of poor dynamic and static speed tracking progress, increased costs, and motor instability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

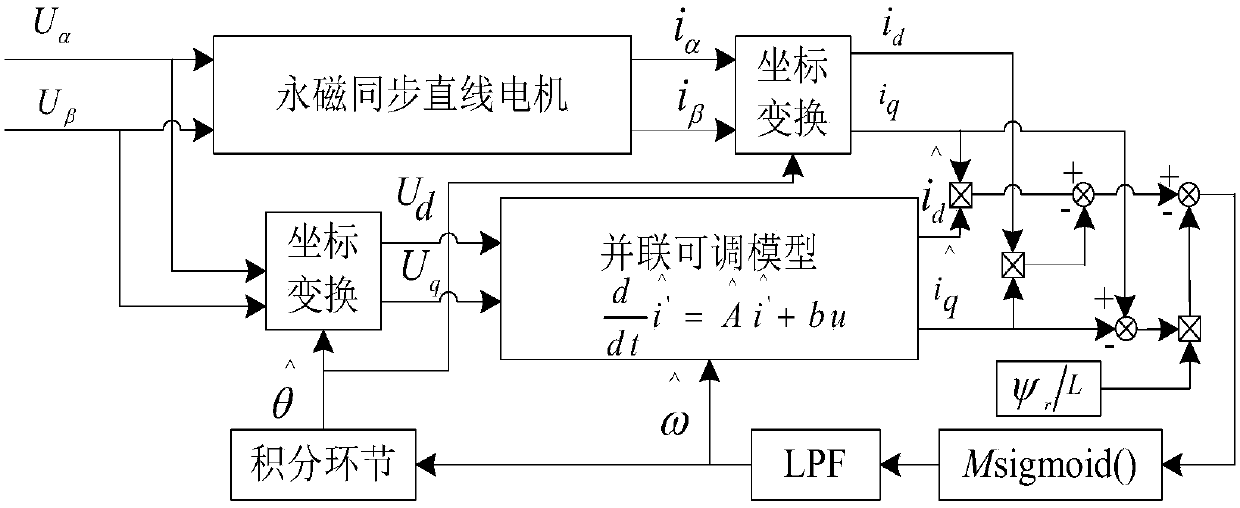

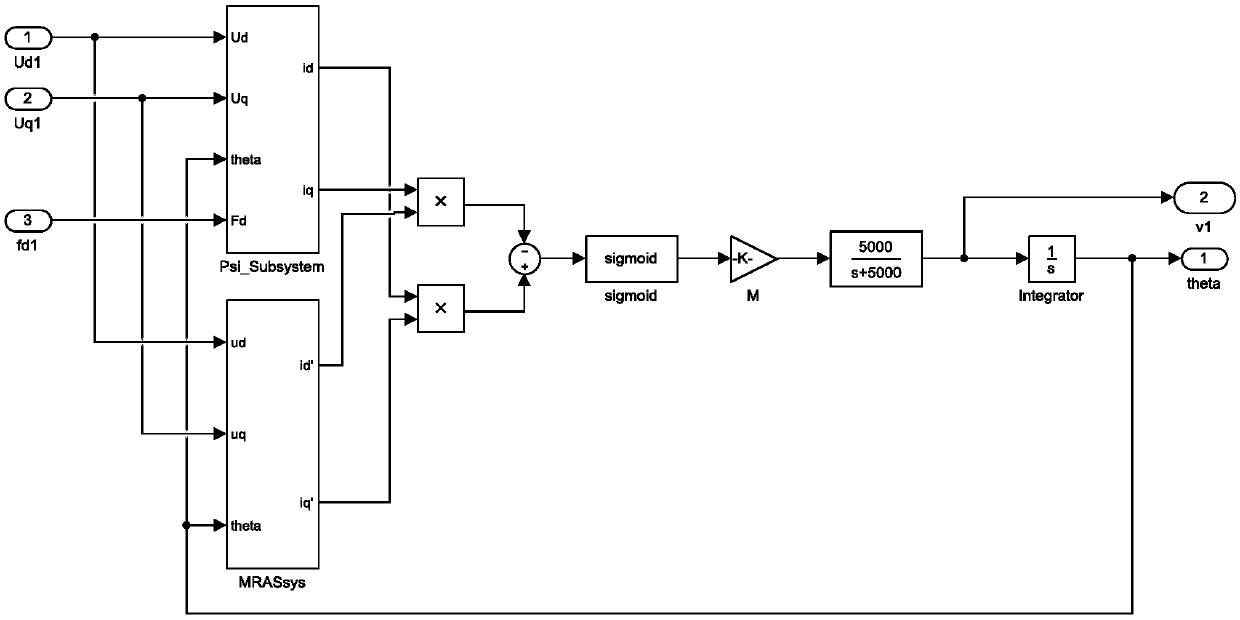

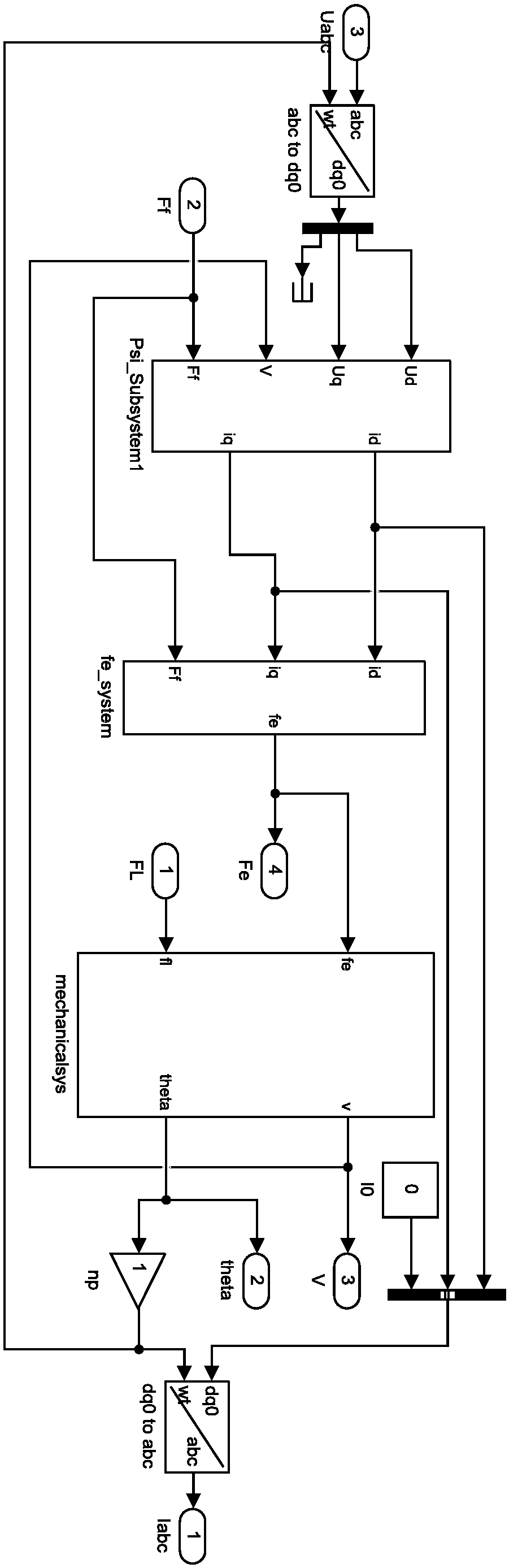

[0060] The specific control process of the permanent magnet synchronous linear motor without speed controller described in this embodiment is as follows:

[0061] (1) Determine and analyze the state parameters of the permanent magnet synchronous linear motor, mainly including the dq axis current i of the reference model d and i q and adjustable model dq axis current with Such as figure 1 As shown, the permanent magnet synchronous linear motor is used as a reference model, and the parallel adjustable model is a current model. According to i d and and i q and The error constructs the sliding surface S, where the coordinate transformation abc-αβ formula is:

[0062]

[0063] The transformation formula αβ-dq of the two-phase stationary coordinate system into the two-phase rotating coordinate system is:

[0064]

[0065] Neglecting the magnetic saturation of the motor core, the magnetic permeability of the permanent magnet is 0, ignoring the eddy current loss and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com