Automated squid processing device

A processing device and squid technology, which are applied in the processing of cephalopods, fish processing, slaughtering, etc., can solve the problems of poor drying effect, large floor space, low drying efficiency, etc., and prolong the mincing time. , easy operation, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

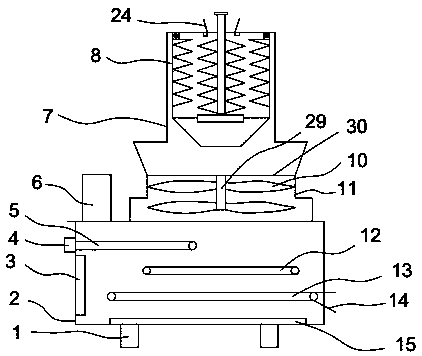

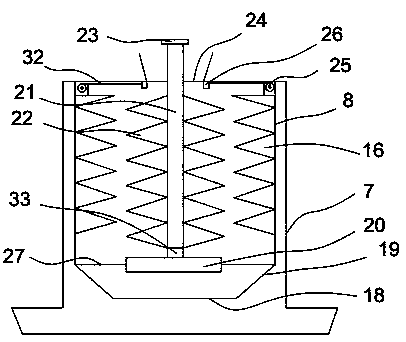

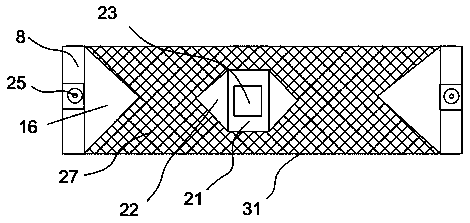

[0020] Such as Figure 1-5 Shown, the technical scheme that the present invention takes for realizing the above object is: automatic squid processing device, comprises mincing device 7, and the lower end of mincing device 7 is connected fan 11, and fan 11 is installed on drying device 2 upper end, and drying device 2 The side is provided with a control panel 4, the lower end of the drying device 2 is provided with a fixed foot 1, the connection between the blower fan 11 and the bottom of the crushing device 7 is provided with a barbed wire 30, and a motor 29 is installed on the top of the blower fan 11, and the output shaft of the motor 29 is provided with a double The rotating blade 10, through the fan provided, makes the external airflow be introduced while generating suction to the squid stuck in the barbed wire to accelerate its falling speed. At the same time, the double rotating blades chop the falling squid again. This device, The structure is simple, the operation is c...

Embodiment 2

[0028] The automatic squid processing device of the present invention has the following working principles: start the motor 23, put the dissected squid into the crushing device 7 from the entrance 24, and after the squid is crushed, suck it into the drying device under the action of the blower fan 11 2, the squid is dried, and the blower 6 is started to blow air in the drying device 2, and the gas is pressed down to prevent the hot air from stringing together. The third conveyor belt 13 is gradually transported to the discharge port 14 to complete the processing process.

[0029] The conventional technologies in the above embodiments are known to those skilled in the art, so they will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com