Mechanically-enhanced electromagnetic shielding film and preparation method thereof

An electromagnetic shielding film and mechanical technology, applied in chemical instruments and methods, and other chemical processes, can solve problems such as low strength and poor toughness, and achieve the effects of gentle reaction process, low price and safe process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

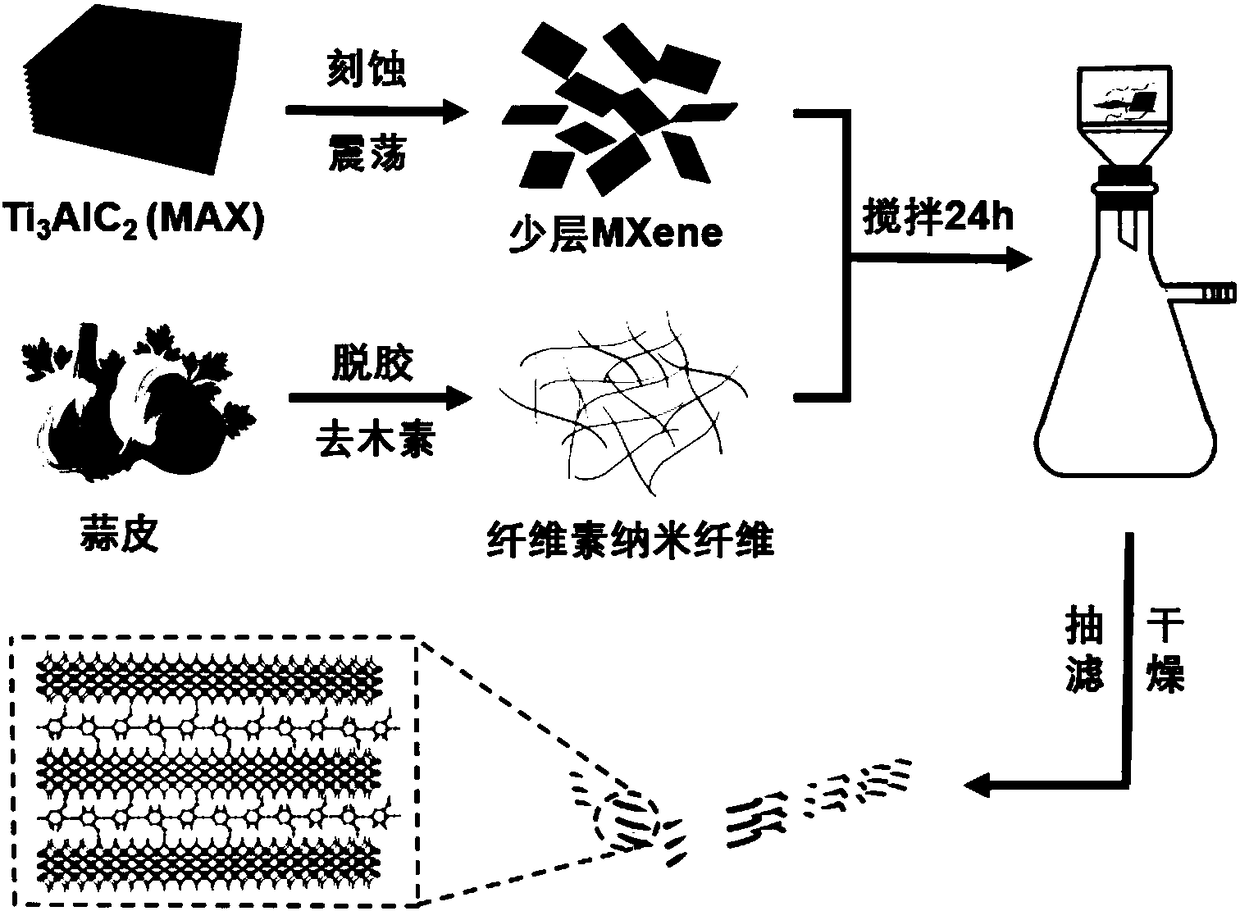

[0043] In the preparation method according to the present invention with Ti 3 AlC 2 and cellulose raw materials as raw materials, Ti 3 AlC 2 The few-layer MXene is prepared by etching and intercalation, and then the cellulose nanofibers are extracted from the garlic skin. Finally, the few-layer MXene and cellulose nanofibers are mixed and stirred according to a certain ratio, and the membrane is formed by suction filtration. This process does not involve HF, etc. Strong oxidant, gentle reaction process, safe process, good uniformity of the obtained product, is an efficient, quick and environment-friendly method for preparing electromagnetic shielding film.

[0044] In the preparation method according to the present invention, the Ti 3 AlC 2 It is preferably a powder with a particle size ≤ 40um. When Ti 3 AlC 2 When the particle size of Al is larger than 40um, the etching will be incomplete due to the too wide Al layer in the block, which will reduce the quality of the o...

Embodiment 1

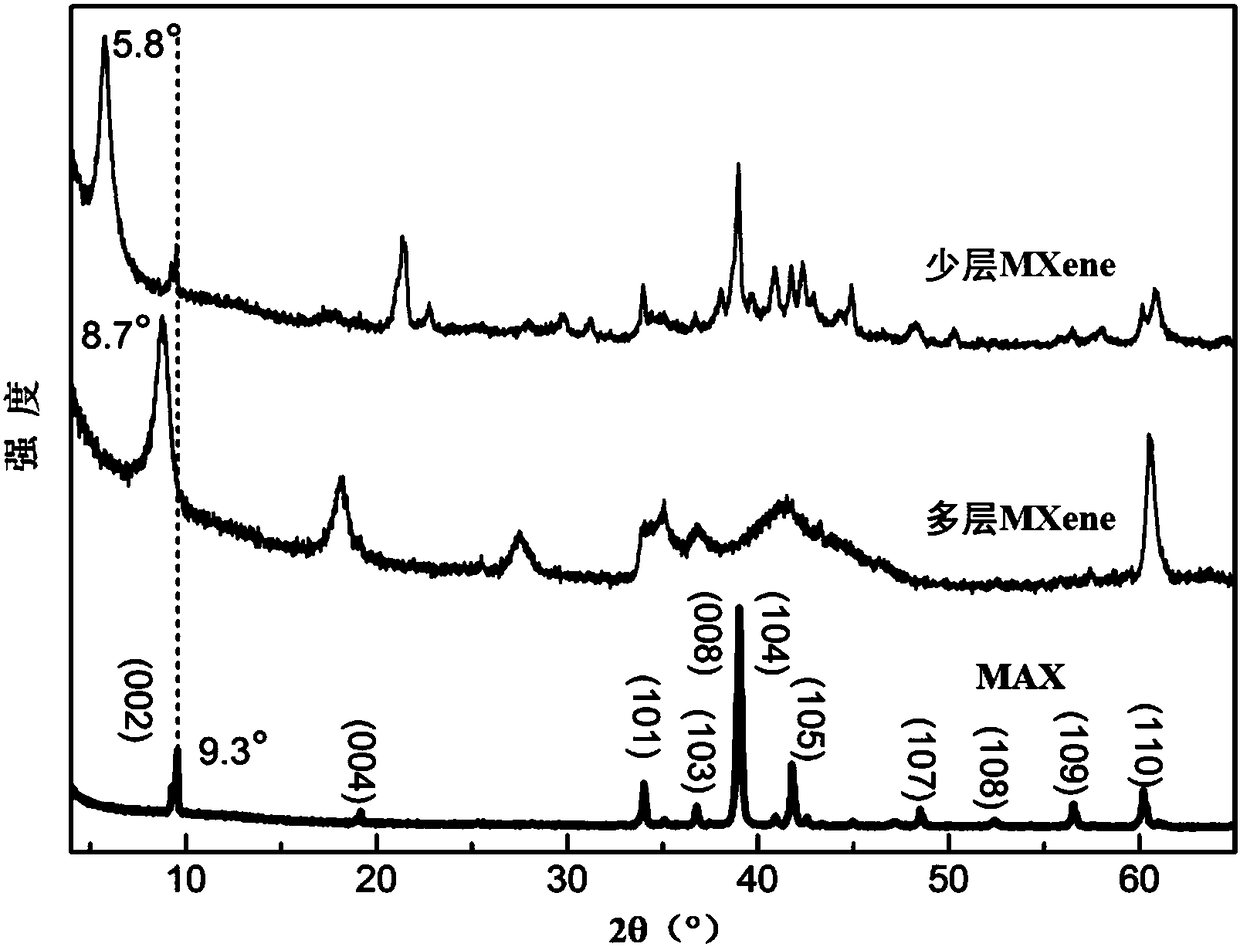

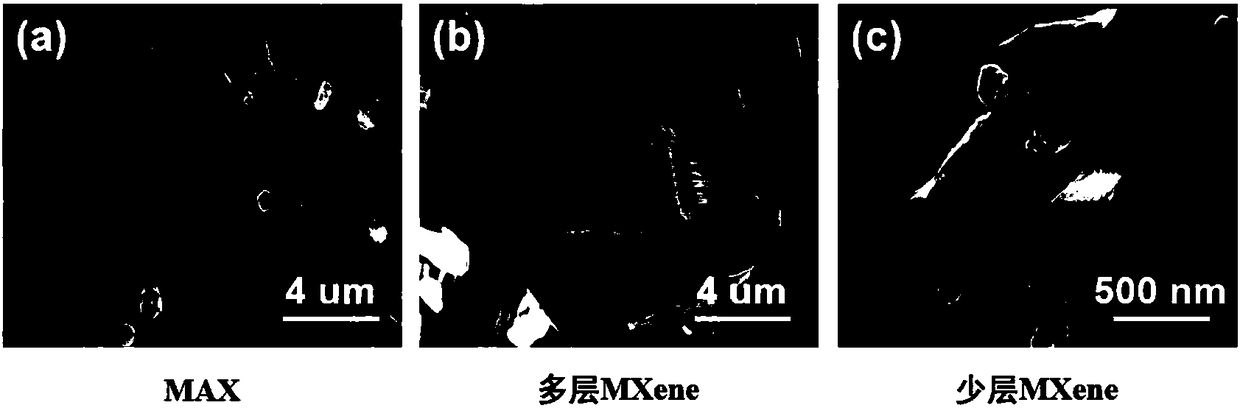

[0050] 1) Preparation of few-layer MXene

[0051] Add 1gLiF into 20mL9M HCl solution and stir until completely dissolved; 3 AlC 2 Add to the HCl solution, stir at 35°C for 24h; centrifuge the obtained suspension at 3500r / min×5min, wash with deionized water until the supernatant pH is ≥ 5, pour out the supernatant to obtain multi-layer MXene precipitates; add 300mL deionized water, shake vigorously for 5min, centrifuge at 3500r / min for 1h, collect the supernatant, and obtain the few-layer MXene.

[0052] It can also be based on the existing literature C.J.Zhang, B.Anasori, A.Seral-Ascaso, S.H.Park, N.McEvoy, A.Shmeliov, G.S.Duesberg, J.N.Coleman, Y.Gogotsi, V.Nicolosi, Adv.Mater.2017, Prepared in the manner described in 29.

[0053] 2) Preparation of cellulose nanofibers

[0054] Disperse 10g of garlic peel in 400mL of 2wt% NaOH solution, react at 140°C for 4h, take out deionized water and wash until neutral; the obtained slurry is dispersed in 400mL of 2wt% H 2 SO 4 In t...

Embodiment 2

[0063] Except that the few-layer MXene dispersion and the CNFs dispersion are at a solid content ratio of 1:4, a mechanically enhanced electromagnetic shielding film containing few-layer MXene with a weight content of 20% (less layer MXene-20%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile fracture stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com