Method for detecting debonding defects of composite material glue bonding structure by using terahertz time-domain spectroscopy

A technology of terahertz time-domain and composite materials, which is applied in the field of terahertz time-domain spectroscopy to detect debonding defects of composite material bonding structures, which can solve problems such as debonding, slow speed, weak bonding, etc., to avoid pollution and damage, Accurate positioning and high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

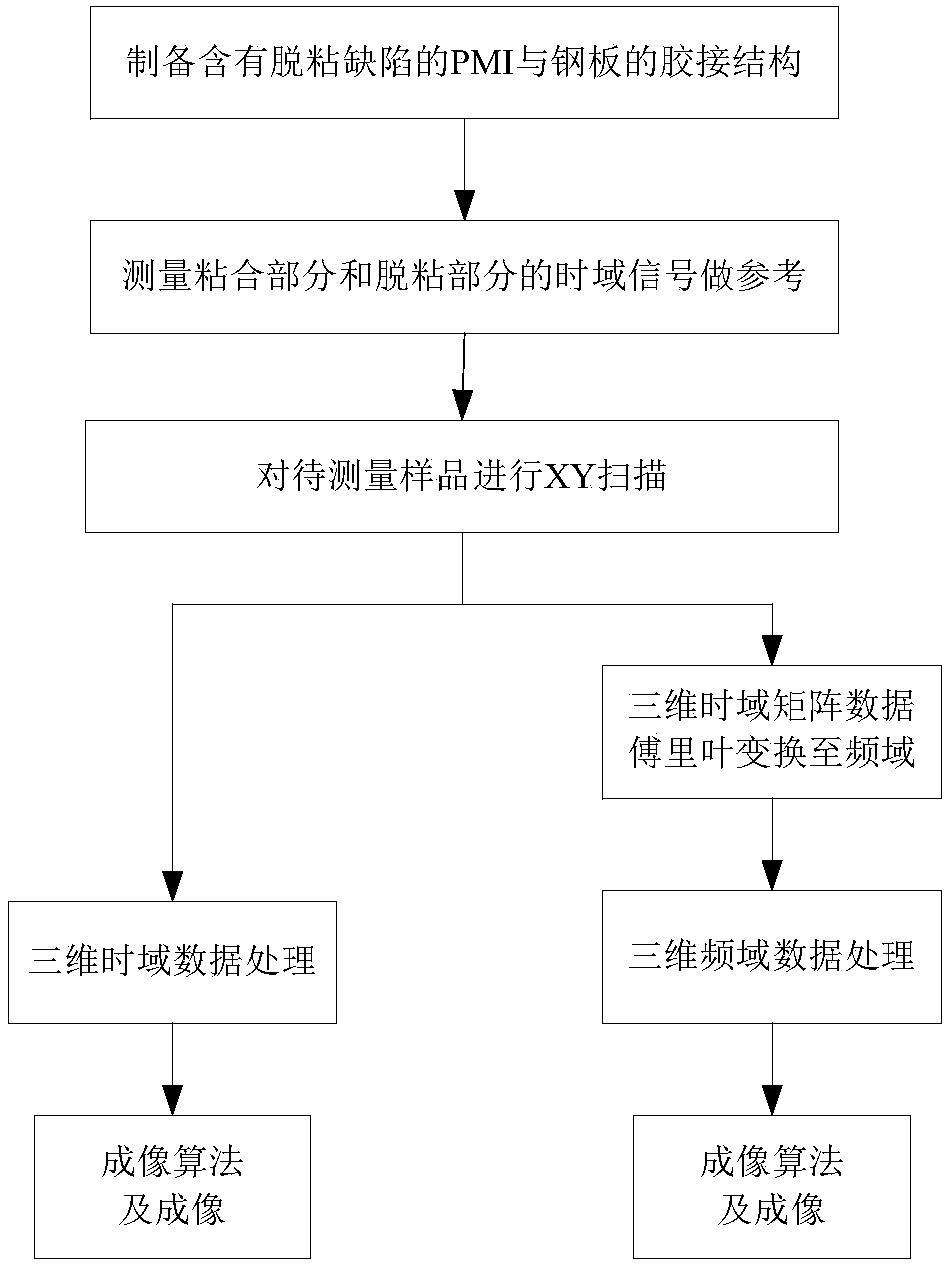

[0062] Example 1: See Figure 1 to Figure 15 As shown, this embodiment provides a method for detecting debonding defects in composite material bonding structures using terahertz time-domain spectroscopy, including the following steps:

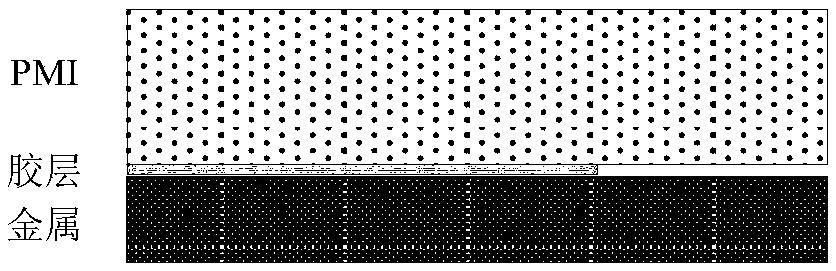

[0063] (1) Sample preparation: a piece of PMI foam material with a thickness of 5mm, a piece of 304 steel plate of the same size with a thickness of 2mm, the glue used for bonding is Gelianghao AB glue, and the PMI foam material and steel plate are glued together , the characteristic of the bonded structure is that part of the area is glued to maintain the bonded state to simulate the non-destructive state of the bonded structure, and the other part is not coated to maintain the unbonded state to simulate the debonding defect state of the bonded structure.

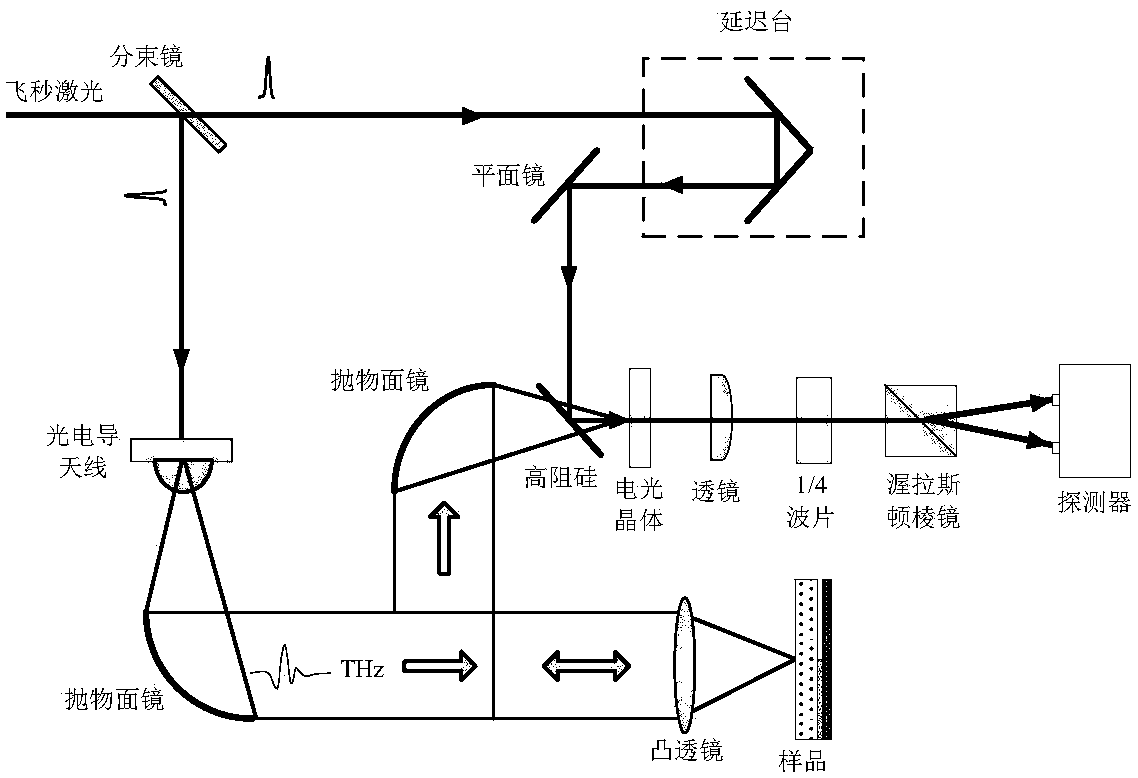

[0064] (2) Experimental test preparation: In order to avoid the influence of water vapor in the air, the terahertz time-domain spectroscopy system was placed in a sealed cover, and dry air ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com