Bending-resistant wire

A bending-resistant and wire-resistant technology, applied in bendable conductors, bendable cables, conductors, etc., can solve the problems of poor mechanical properties of wires, easily broken conductors, and easily broken protective layers, and achieve good bending fatigue resistance. , not easy to break, good bulletproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

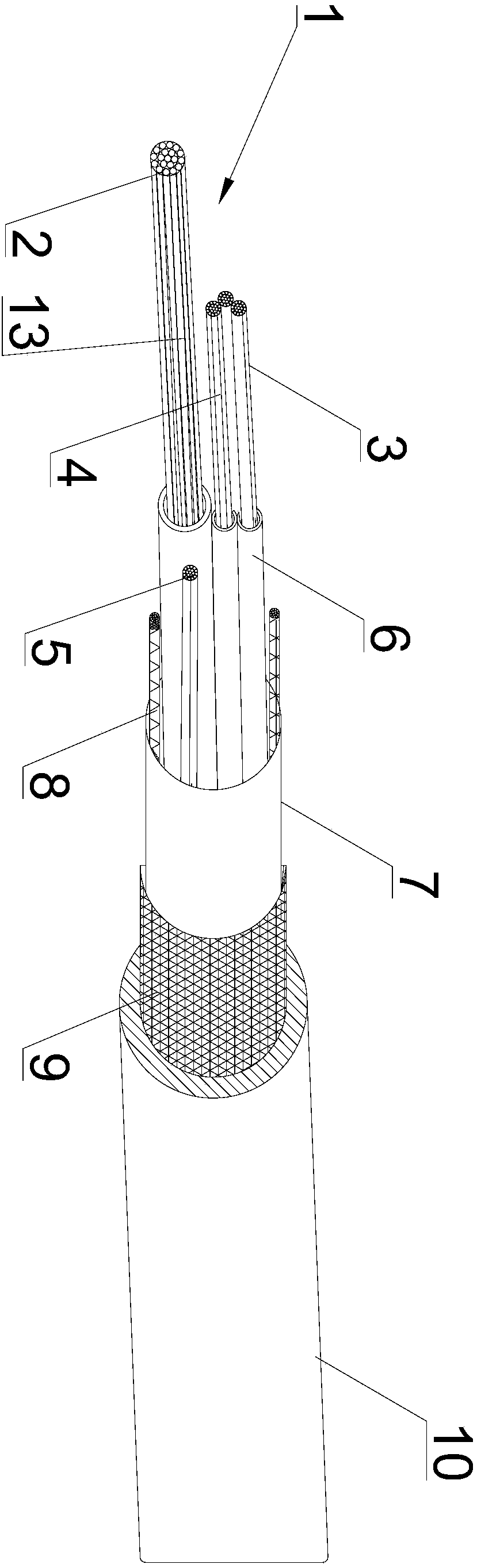

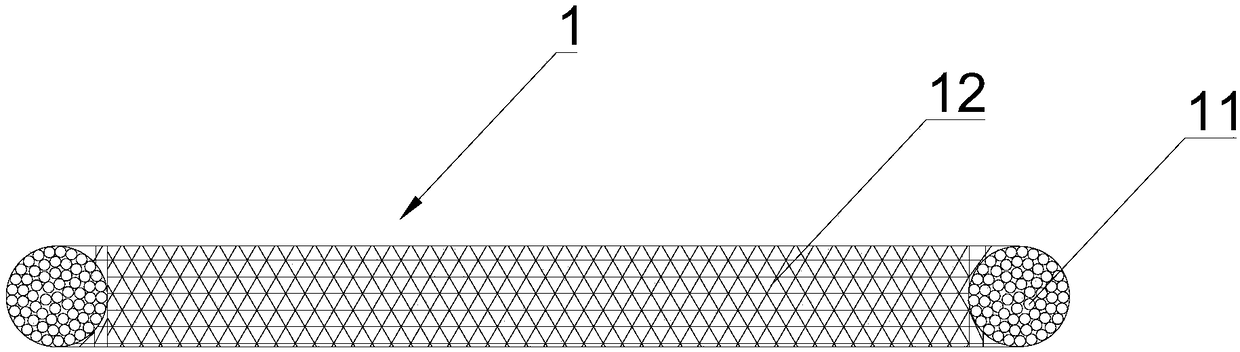

[0025] This embodiment provides a bending-resistant wire, which is used to transmit power or data signals in electronic equipment sinks, such as Figure 1-2 As shown, the bending-resistant wire includes a copper wire 1, and the copper wire 1 includes an ultra-high molecular weight polyethylene fiber wire 11 and a copper foil layer 12 wound on the surface of the ultra-high molecular weight polyethylene fiber wire 11, The surface of the copper foil wire layer 12 is also wound with a copper wire layer 13, the copper wire layer 13 plays the role of signal transmission, and the copper foil wire is one or more, and is wound around the On the surface of the ultra-high molecular weight polyethylene fiber wire 11 , the diameter of the ultra-high molecular weight polyethylene fiber wire 11 is 0.3 mm, and there are one or more copper wires, which are wound on the surface of the copper foil wire layer 12 .

[0026] The bending resistance of the copper wire 1 filled with ultra-high molecul...

Embodiment 2

[0031] This embodiment provides a bending-resistant wire, which is used to transmit power or data signals in electronic equipment sinks, such as Figure 1-2 As shown, the bending-resistant wire includes a copper wire 1, and the copper wire 1 includes an ultra-high molecular weight polyethylene fiber wire 11 and a copper foil layer 12 wound on the surface of the ultra-high molecular weight polyethylene fiber wire 11, The surface of the copper foil wire layer 12 is also wound with a copper wire layer 13, the copper wire layer 13 plays the role of signal transmission, and the copper foil wire is one or more, and is wound around the On the surface of the ultra-high molecular weight polyethylene fiber wire 11 , the diameter of the ultra-high molecular weight polyethylene fiber wire 11 is 0.1 mm, and the copper wire is also one or more, which are wound and arranged on the surface of the copper foil wire layer 12 .

[0032] The bending resistance of the copper wire 1 filled with ultr...

Embodiment 3

[0037] This embodiment provides a bending-resistant wire, which is used to transmit power or data signals in electronic equipment sinks, such as Figure 1-2 As shown, the bending-resistant wire includes a copper wire 1, and the copper wire 1 includes an ultra-high molecular weight polyethylene fiber wire 11 and a copper foil layer 12 wound on the surface of the ultra-high molecular weight polyethylene fiber wire 11, The surface of the copper foil wire layer 12 is also wound with a copper wire layer 13, the copper wire layer 13 plays the role of signal transmission, and the copper foil wire is one or more, and is wound around the On the surface of the ultra-high molecular weight polyethylene fiber wire 11 , the diameter of the ultra-high molecular weight polyethylene fiber wire 11 is 0.8 mm, and the copper wire is also one or more, which are wound and arranged on the surface of the copper foil wire layer 12 .

[0038] The bending resistance of the copper wire 1 filled with ultr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com