Ultrafine high-dispersed rubber ingredient production device

A technology for dispersing rubber and production equipment, which is applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc. It can solve the problem of dust flying, poor compatibility of pre-dispersed insoluble sulfur rubber masterbatch to rubber, Low production efficiency and other issues to achieve the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

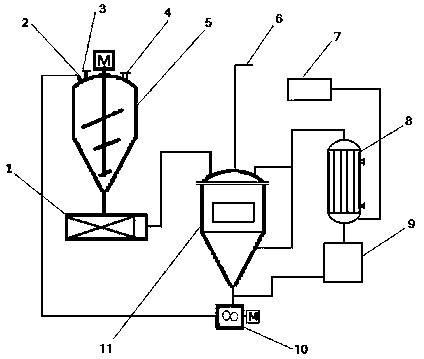

[0025] The production device of 1,000 tons of ultra-fine and high-dispersion rubber vulcanization accelerator per year, including: agitating mixer (5) is a cylindrical stainless steel mixing vessel with a cone-shaped bottom of 2 cubic meters, and an ultra-fine mill (1) is DSJTM-80 Shearing colloid mill, solid-liquid separator (11) is a cylindrical stainless steel filter with a diameter of 800mm, a diameter of 1000mm, and a two-layer stainless steel filter with a diameter of 10 microns at the bottom. The grinding aid circulating pump (10) is DN40 stainless steel Centrifugal pump, hot nitrogen pipe (6) is DN25 stainless steel pipe, grinding aid intermediate tank (9) is 2 cubic meter vertical stainless steel tank, vacuum unit (7) is RPP-54-90 water jet vacuum unit, condensing The heat exchanger (8) is a stainless steel tube heat exchanger with a heat exchange area of 20 square meters.

[0026] The lower outlet pipe of the stirring mixer (5) is connected with the inlet pipe of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com