Tunnel construction wastewater management technology

A tunnel construction and wastewater technology, applied in the field of water pollution control, can solve the problems of low wastewater treatment efficiency, poor treatment effect, and difficulty in meeting discharge standards, and achieve the effects of reducing transportation costs, increasing processing speed, and easy precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

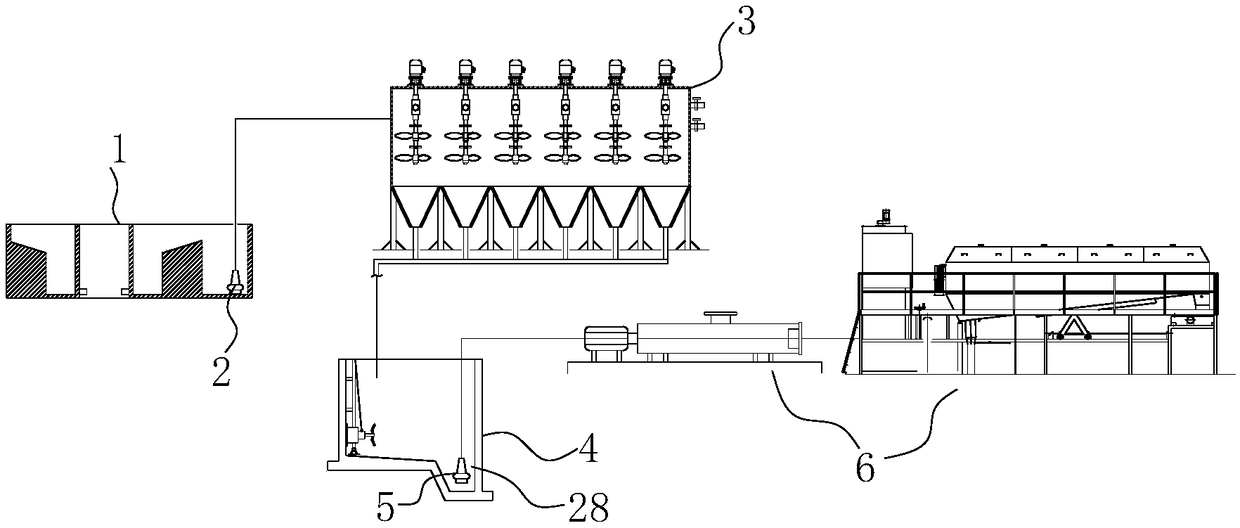

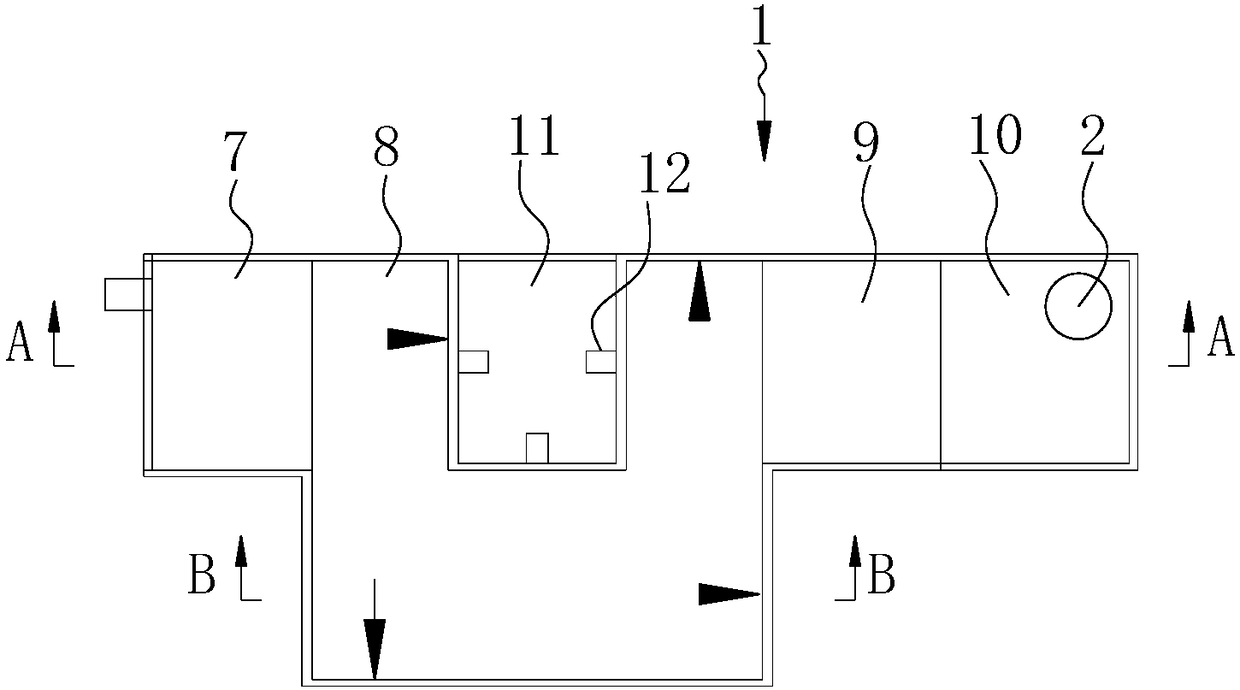

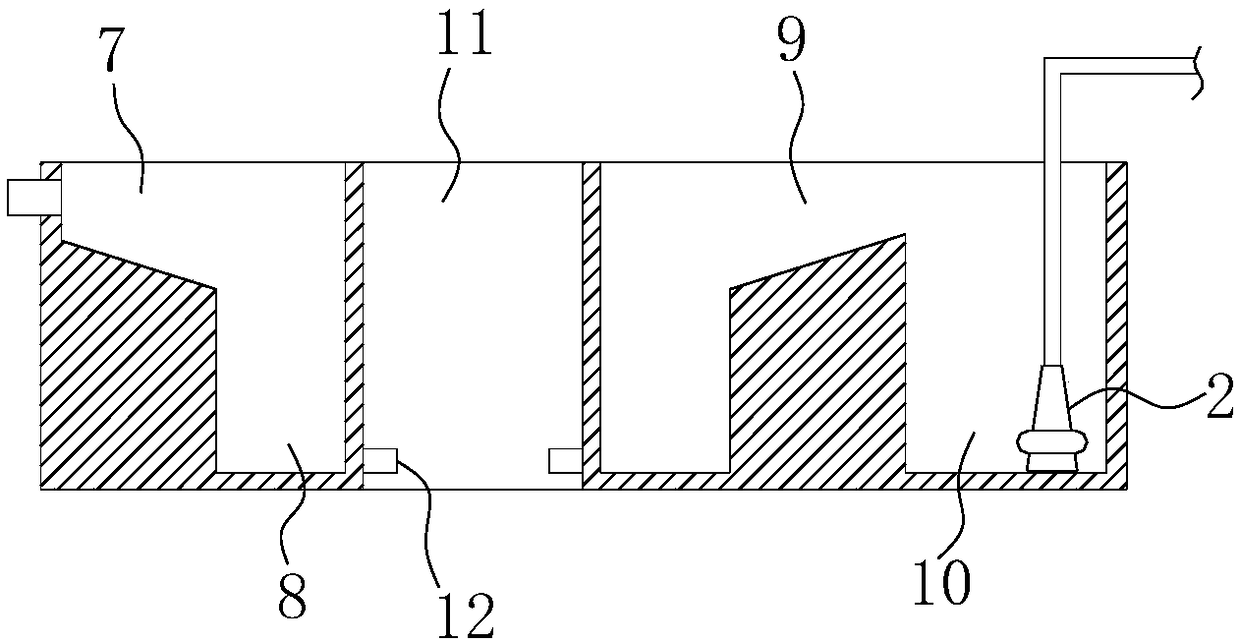

[0027] combine Figure 1-6 The shown tunnel construction wastewater treatment process mainly adopts the following equipment and facilities: grit chamber 1 , flocculation settler 3 , mud pond 4 , and sludge dewaterer 6 . The grit chamber 1 and the mud pond 4 are constructed on-site at the construction site, and concrete pond bodies are usually used. After the flocculation settler 3 and the sludge dewatering machine 6 are manufactured, they are assembled at the tunnel construction site. The grit chamber 1, the flocculation-settler 3, the mud pond 4, and the sludge dewatering machine 6 can all adopt existing conventional settings or commercially available conventional models, such as the grit chamber 1 is a simple rectangular tank body with one end The water inlet is set, and the first pump machine 2 is set at the other end. The tunnel construction waste water is passed into the grit chamber 1 through the water inlet, and then undergoes natural sedimentation, and is finally pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com