Intelligent warp-knitting-machine needle-bed headstock speed-range variable motion system

A warp knitting machine needle and kinematic system technology, applied in the field of warp knitting machines, can solve problems such as unadjustable movement speed and amplitude of the ejector rod, long auxiliary time, and affecting the effective working time of the warp knitting machine, and achieve undulating speed and continuous stroke Effects of adjustable, reduced labor and maintenance costs, and elimination of lubricating oil contamination problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

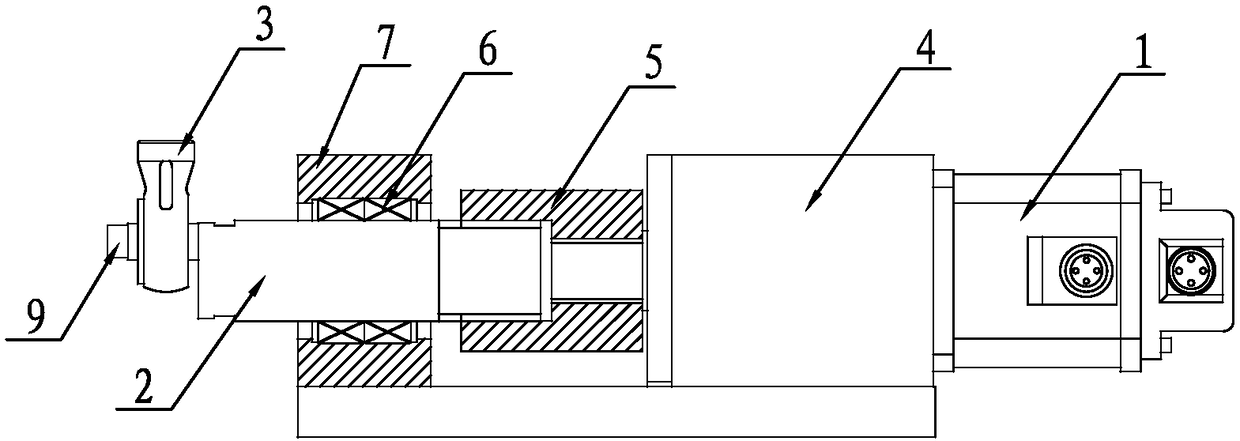

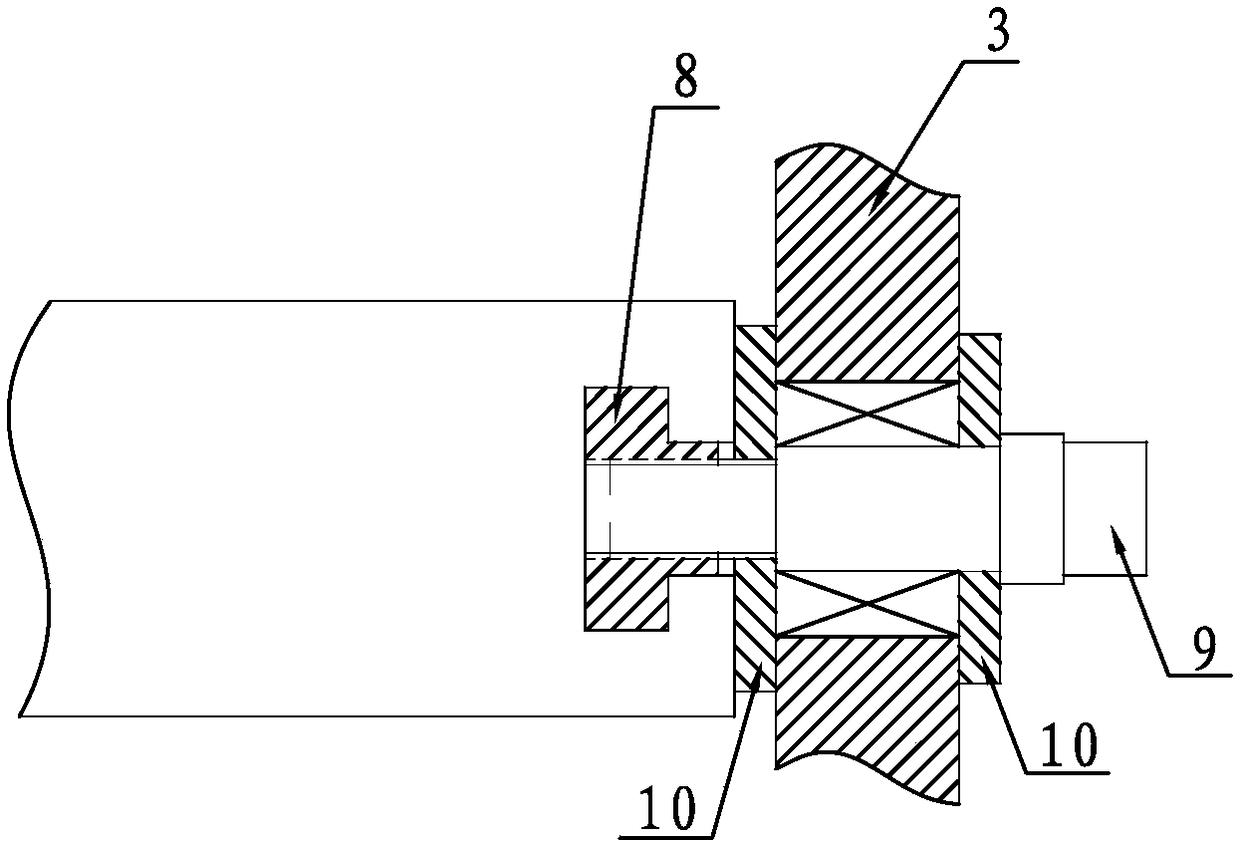

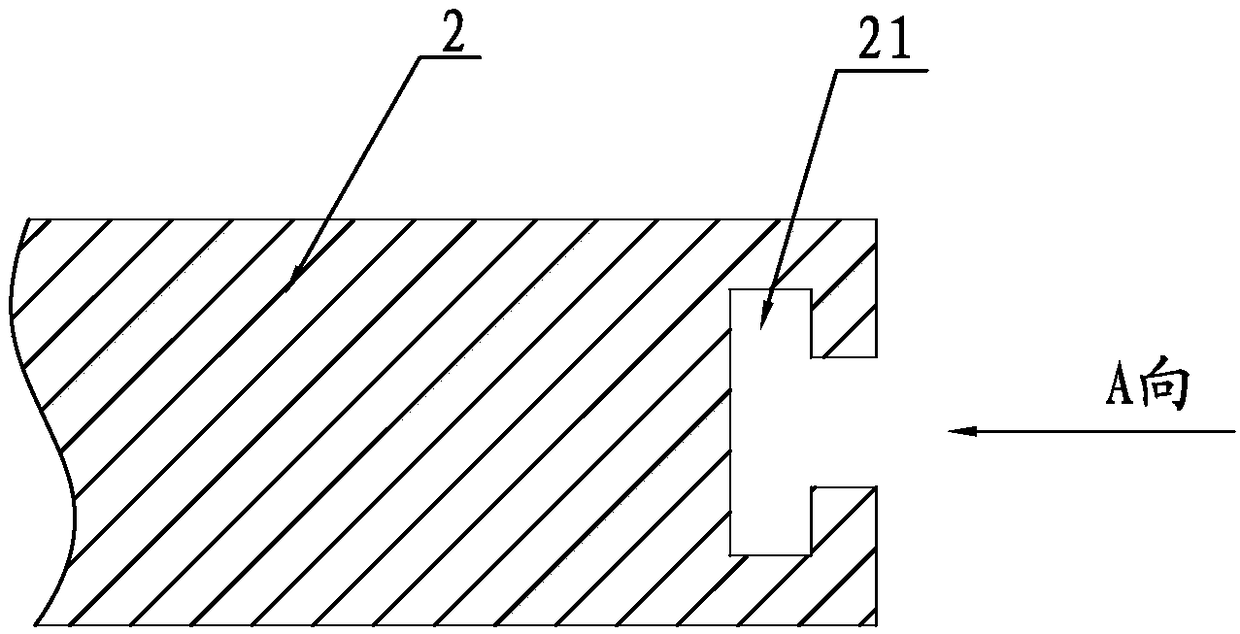

[0031] An intelligent warp knitting machine needle bed ejector rod variable speed variable range motion system, such as Figure 1-5 As shown, it includes a variable speed motor 1, a rotating shaft 2, a needle bed tappet seat 3, a reducer 4, a coupling 5, a main shaft bearing 6, a bearing seat 7, a slider 8, a locking mandrel 9 and an axial gasket 10 The variable speed motor 1 drives the rotating shaft 2 through the reducer 4 and the shaft coupling 5, and the rotating shaft 2 is installed on the bearing seat 7 through the main shaft bearing 6. The variable speed motor 1 is a DC frequency conversion motor, and the needle bed tappet seat 3 is adjusted radially The device is installed on the extended end of the rotating shaft 2, and the radial position of the needle bed tappet seat 3 along the rotating shaft 2 can be adjusted. The slider 8 corresponding to the groove 21 and the locking mandrel 9, the slider 8 is sleeved in the radial chute 21 of the rotating shaft 2, and an intern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com