Method for releasing plugging of gas field wellbore

A gas field and wellbore technology, which is applied in the field of gas field chemistry, can solve the problems of lack of methods for gas wellbore cleaning and plugging removal, and achieve remarkable plugging removal effects, rapid gas production and oil production, and significant drop in pressure difference between oil casings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of the acidic plugging agent is as follows: According to the proportion, the organic sulfonic acid solution and the corrosion inhibitor solution are mixed and stirred for 25-35 minutes, then the drainage aid solution A is added, and the acidic blocking agent is obtained by mixing evenly.

[0045] The preparation method of the alkaline chelating agent is as follows: according to the proportion, the polyamine polyacid salt solution and the drainage aid solution B are mixed and stirred for 25-35 minutes to obtain the alkaline chelating agent.

[0046] Acidic plugging agent: at normal pressure and temperature, the organic sulfonic acid solution with a concentration of 10% to 14% by mass has a positive effect on CaCO 3 The scale dissolution rate is 82.55-92.48%, and the scale dissolution capacity is 66.04-73.98 g / L. At normal pressure and 90°C, the corrosion rate of 80S with 10% organic sulfonic acid solution is 83.44 g / (m 2 • h), after adding 1% corr...

Embodiment 1

[0049] Preparation of acid plugging agent: Take 75 parts of organic sulfonic acid solution with mass percentage concentration of 10%, 2 parts of corrosion inhibitor solution with mass percentage concentration of 0.5%, mix and stir for 25min, and then add 0.5 mass percentage concentration % of drainage aid solution A 10 parts, mixed uniformly to obtain acid plugging remover.

[0050] Preparation of alkaline chelating agent: take 80 parts of polyamine polysalt acid salt solution with a mass percentage concentration of 10%, and 15 parts of drainage aid solution B with a mass percentage concentration of 0.5%, mix and stir for 25 minutes to obtain an alkaline chelating agent mixture.

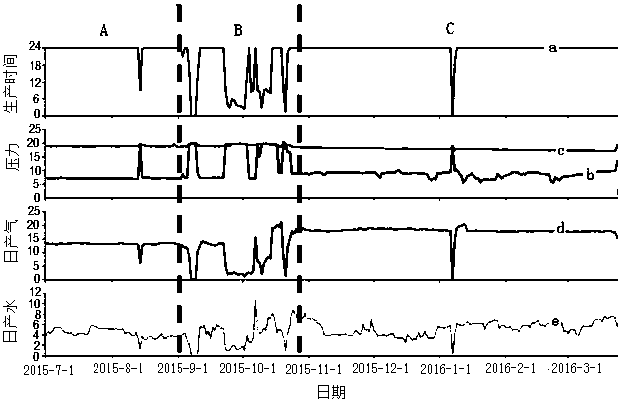

[0051]During the normal generation process of Well 1# in the gas field, the pressure difference between the oil casing and the casing is about 1MPa. figure 1 As shown, the oil-casing pressure difference gradually increased from 1.00MPa to 10.00MPa, and the gas well production increased from the init...

Embodiment 2

[0053] Preparation of acidic plugging agent: Take 78 parts of organic sulfonic acid solution with mass percentage concentration of 12%, 3 parts of corrosion inhibitor solution with mass percentage concentration of 0.5%, mix and stir for 26min, then add 0.5 mass percentage concentration % of drainage aid solution A 19 parts, mixed uniformly to obtain acid plugging agent.

[0054] Preparation of alkaline chelating agent: take 85 parts of polyamine polysalt acid salt solution with a mass percentage concentration of 11%, and 15 parts of drainage aid solution B with a mass percentage concentration of 0.5%, mix and stir for 26 minutes to obtain an alkaline chelating agent mixture.

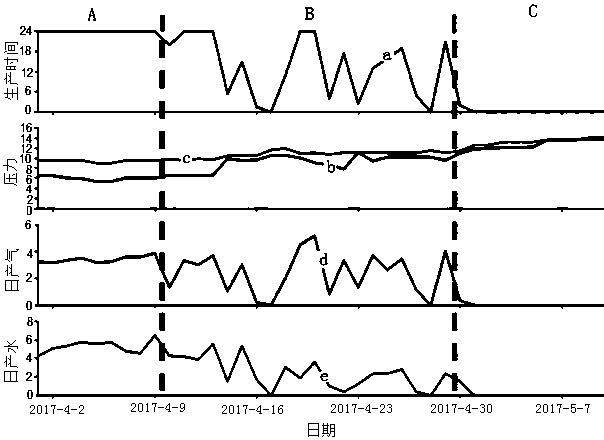

[0055] During the normal generation process of well 2# in the gas field, the oil casing pressure difference is about 1 MPa. With the extension of production time, if figure 2 As shown, the oil-casing pressure difference gradually increased from 1.00 MPa to 4.00 MPa, and the production of the gas well i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com