High-stress roadway surrounding rock liquid-phase plasma blasting pressure relief method

A liquid-phase plasma, blasting and pressure-relieving technology, applied in blasting and other directions, can solve the problems of difficulty in precise control of the energy of explosive explosions, damage to the surrounding rock at the top of the surrounding rock at the side of the roadway, and endangering the health and safety of operators. detrimental effects, improved stress states, improved efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

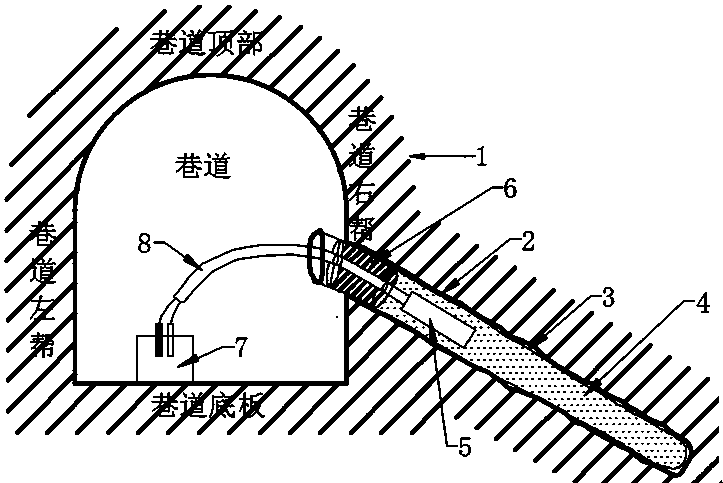

[0026] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0027] The method for depressurizing the liquid-phase plasma blasting of the surrounding rock of the high-stress roadway of the present invention, the specific steps are as follows:

[0028] 1) Check and clean up the roadway where the pressure relief blasting is to be carried out. According to the designed position, angle, diameter and depth of the blast hole, drill on one side or both sides of the side of the roadway, or on the floor of the roadway. Pressure relief hole;

[0029] 2) Use a wooden stick to gently send a plastic bag equivalent in diameter and depth to the blast hole into the pressure relief hole 2, and place the open end of the plastic bag 3 outside the pressure relief hole;

[0030] 3) Insert the rubber hose connected to the electrolyte storage tank into the plastic bag 3 in the blasthole 2, open the infusion valve, and inject the electroly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com