Proton-exchange-membrane fuel cell, complete equipment and automatic control method

A proton exchange membrane, fuel cell technology, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve problems such as large overshoot, and achieve the effect of improving operating life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

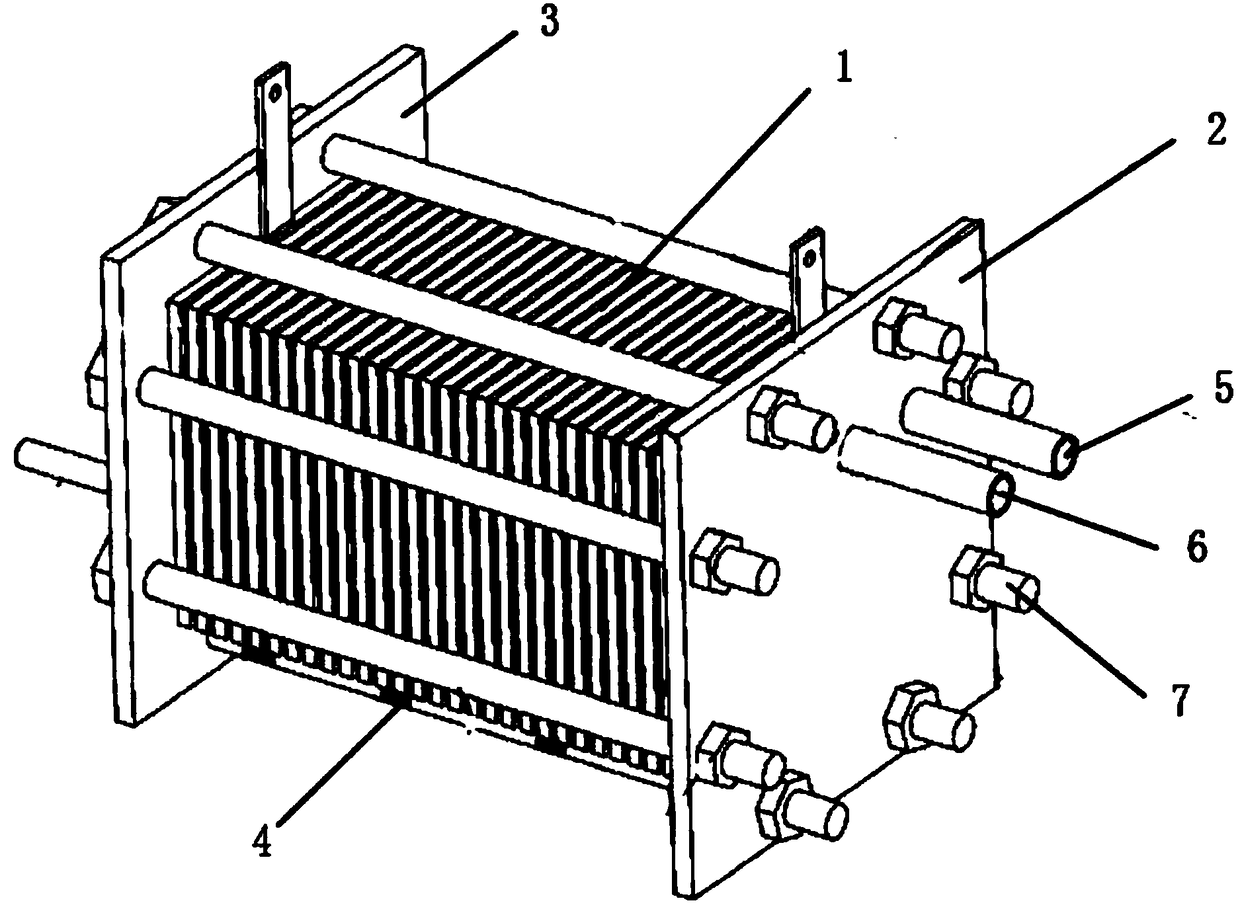

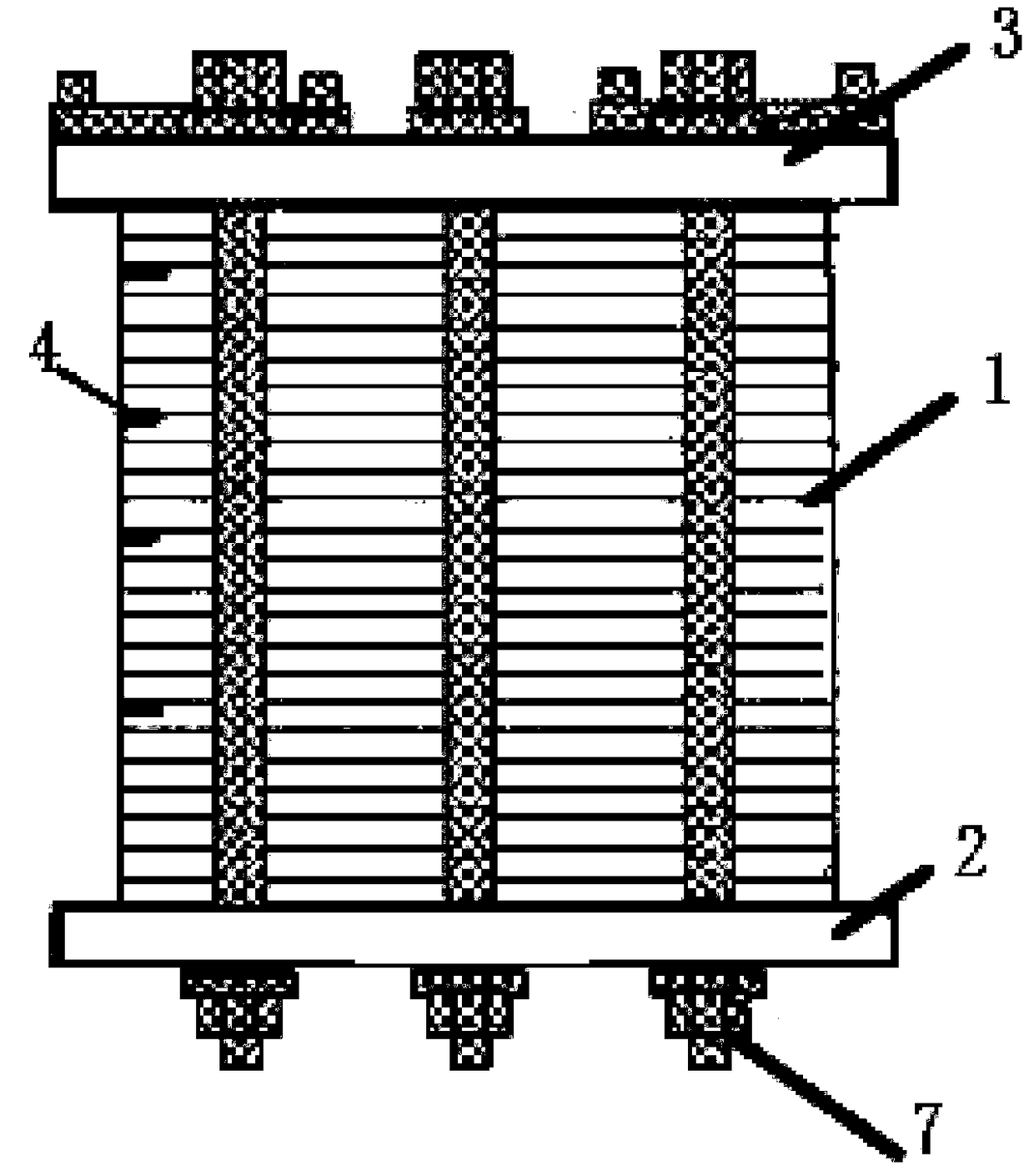

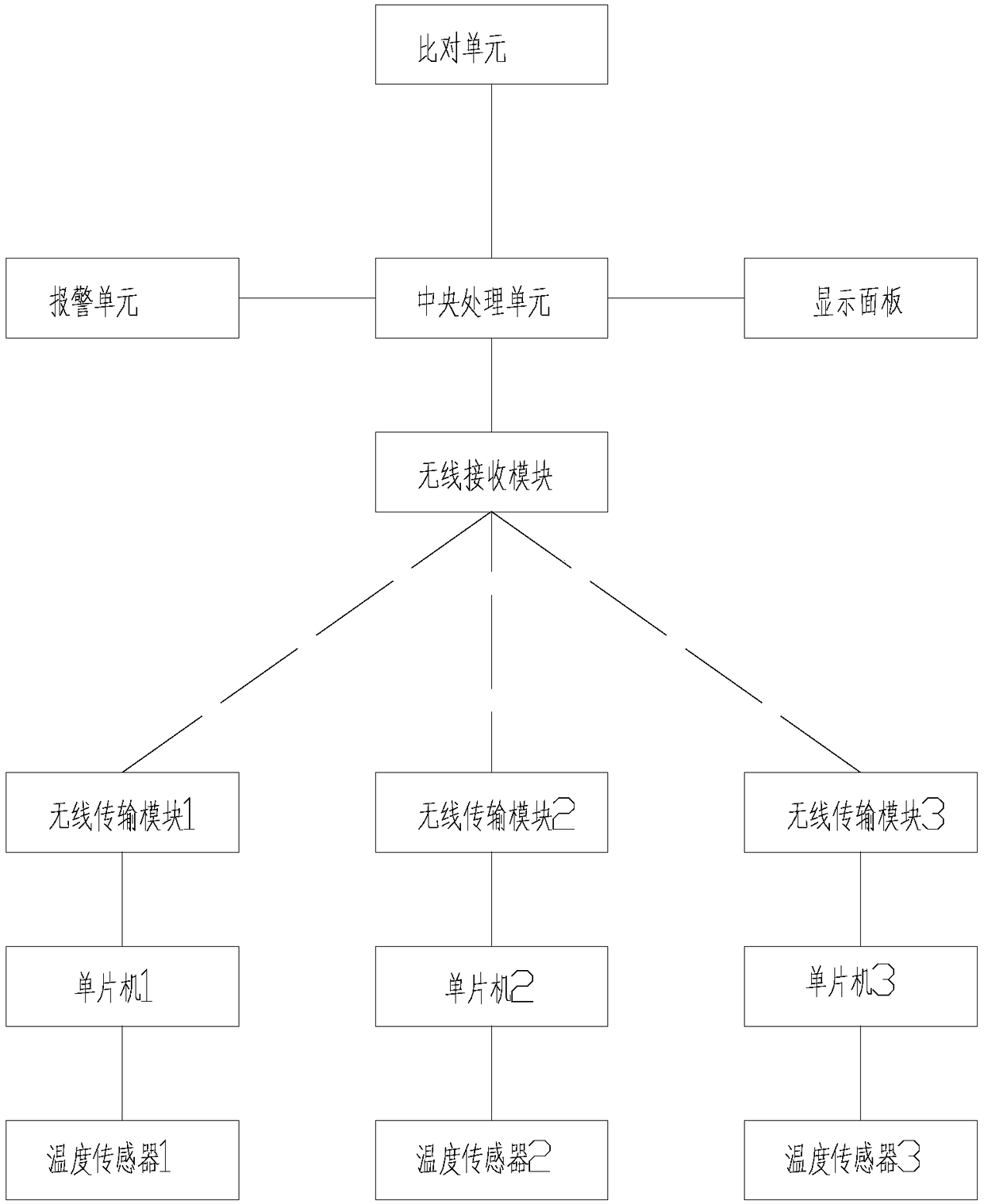

[0029] like figure 1 and figure 2 The shown proton exchange membrane fuel cell provided by the present invention includes a lower clamping plate 2 and an upper clamping plate 3, and a plurality of fuel cell plates 1 stacked on each other are installed between the lower clamping plate 2 and the upper clamping plate 3, and the lower clamping plate 2 and the upper clamping plate 3 are fastened by fixing rods 7; a temperature sensor 4 is provided between adjacent fuel cell plates 1. The temperature on the fuel cell board 1 can be better directly monitored by such a structure; the proton exchange membrane fuel cell is also provided with a hydrogen inlet pipe 5 and an air inlet pipe 6, which are respectively used for inputting into the fuel cell board 1 hydrogen and oxygen. In one embodiment, there are multiple temperature sensors 4 , which can detect the temperatures of different fuel cell boards 1 .

[0030] In the present invention, the temperature value obtained by the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com