Photocatalytic equipment with online automatic cleaning function

An automatic cleaning and photocatalytic technology, which is applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using liquids, etc., can solve the problems of long cleaning cycle, shortened service life of ultraviolet lamp tubes, low cleaning efficiency, etc., to achieve The effect of improving effectiveness and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

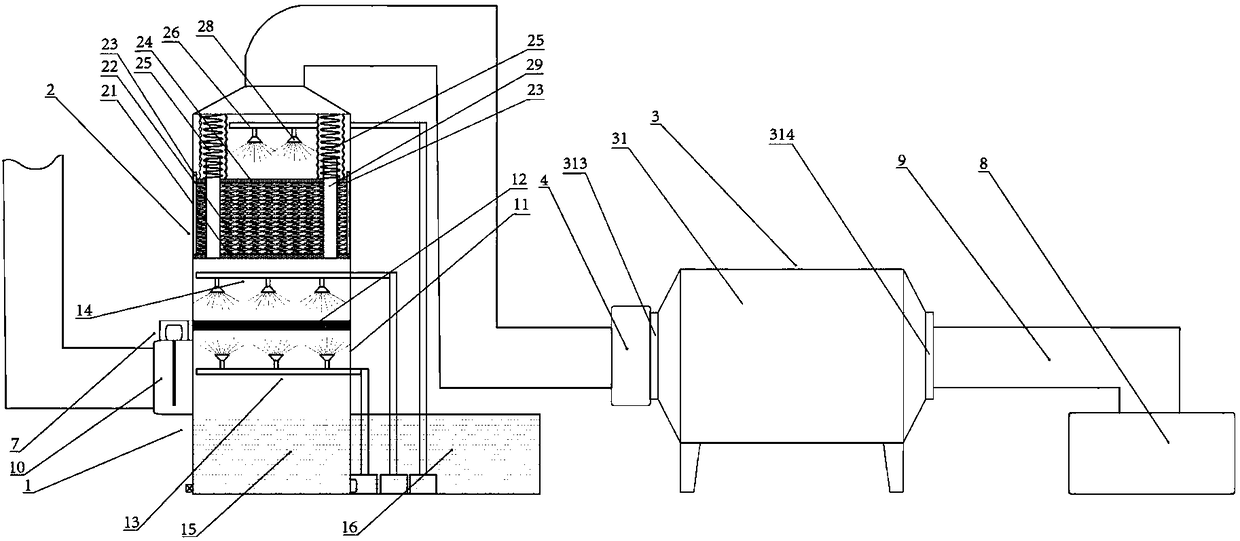

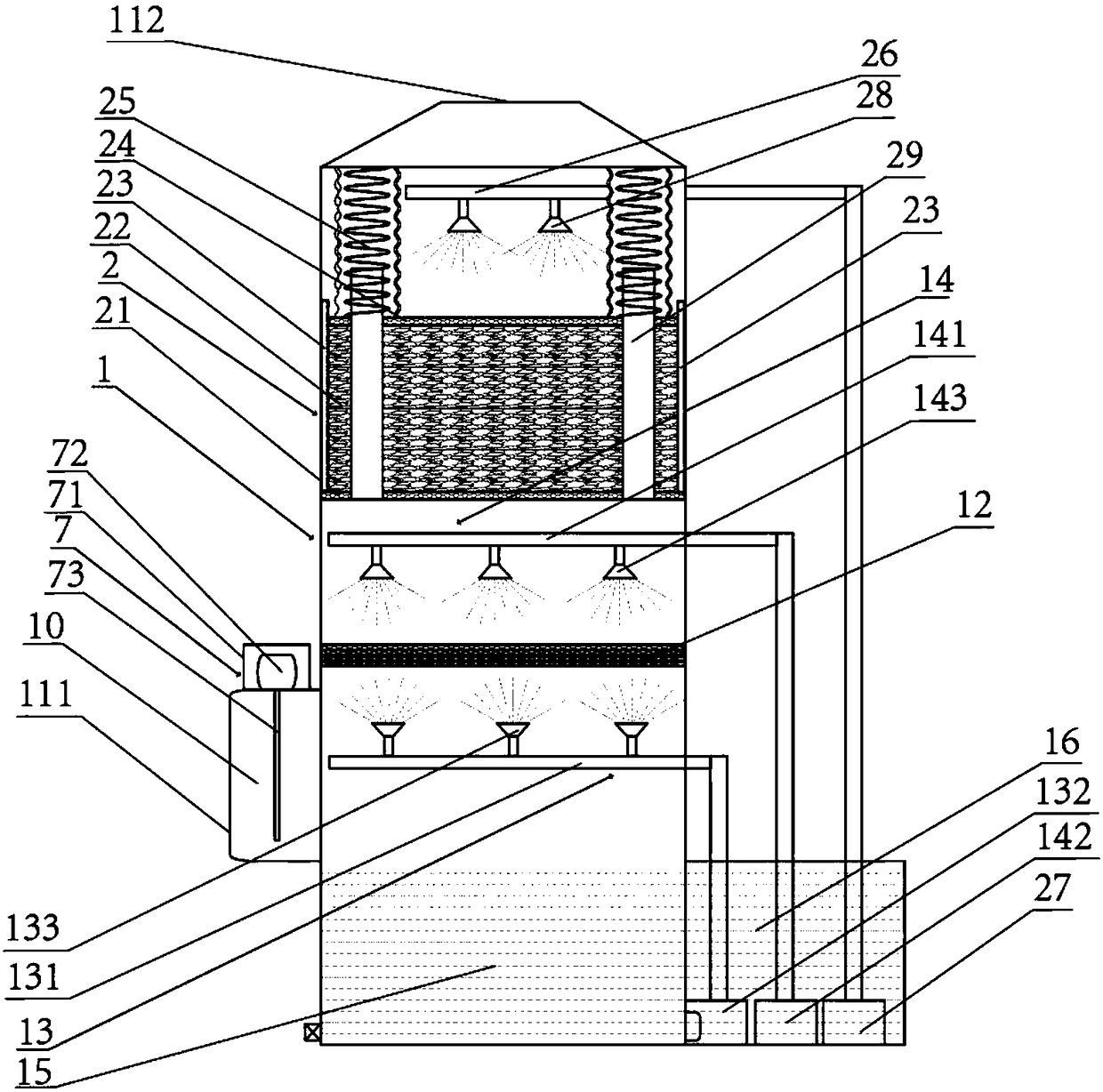

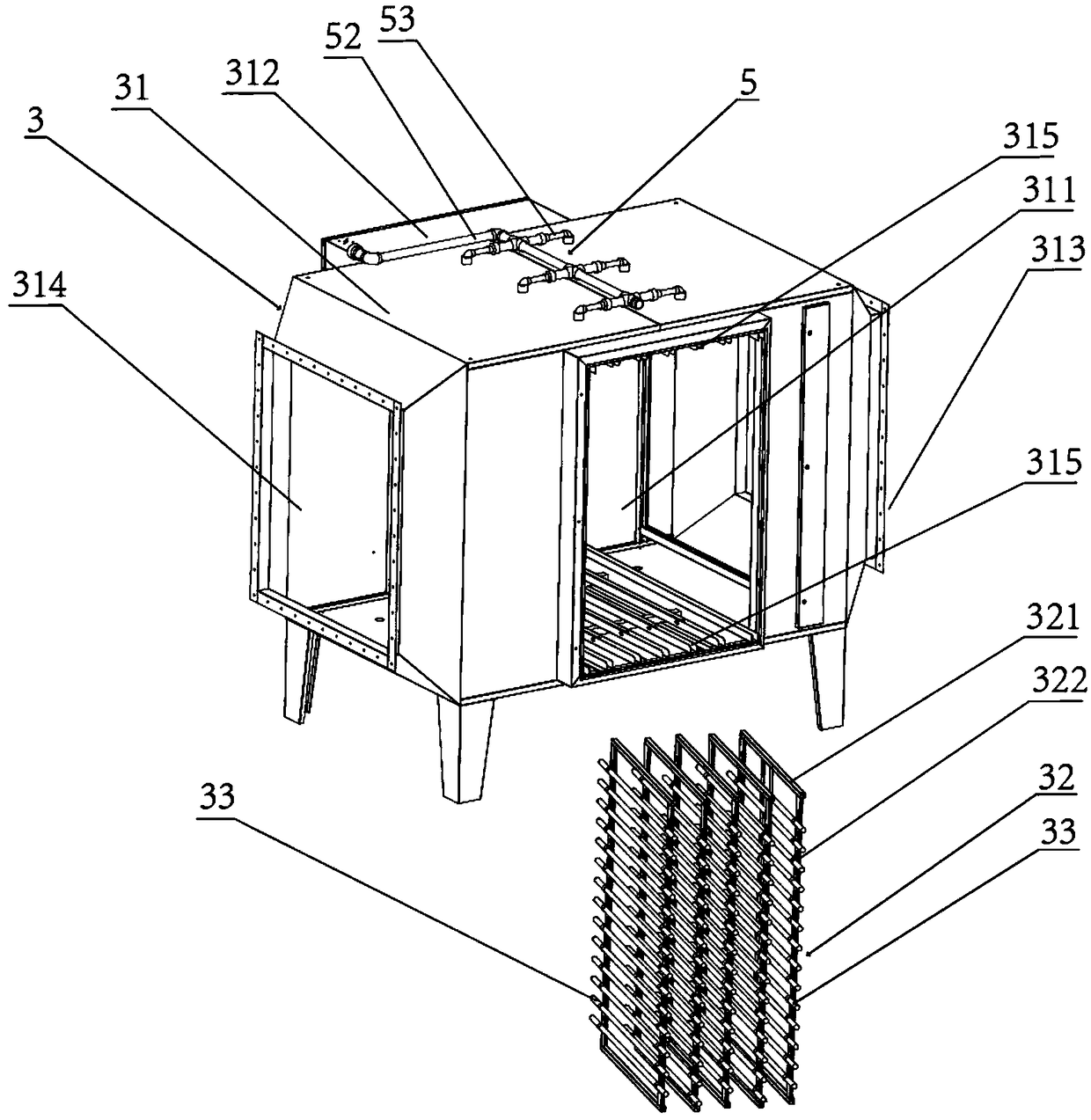

[0030] The present invention will be further elaborated below in conjunction with accompanying drawing, wherein, the direction of the present invention is with figure 1 as standard.

[0031] like Figure 1 to Figure 11As shown, the photocatalytic equipment with online automatic cleaning function of the present invention includes a spray washing system 1, an electrocatalytic oxidation system 2, a photocatalytic oxidation device 3, an oil mist separation device 4, an online cleaning device 5, an ultrasonic decontamination Generating device 6, smoke and dust condensing device 7, high-pressure induced draft fan 8 and induced air duct 9, wherein:

[0032] The spray water washing system 1 is used to wash and filter the dust particles and flue gas in the organic waste gas. The spray water washing system 1 includes a spray water washing tower body 11, a smoke filter device 12, a water washing spray device 13, and a backwash spray device 14 , water tank 15 and circulating pool 16;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com