A kind of animal oil extraction method

An extraction method and animal oil technology, which are applied in the production of fat oil/fat, separation of fat oil/fat, and fat generation, etc., can solve the problems of easy residual solvent, affecting the quality of extracted fat, and inability of further efficient utilization of nutrients, so as to retain protein activity. , to solve the effect of protein inactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

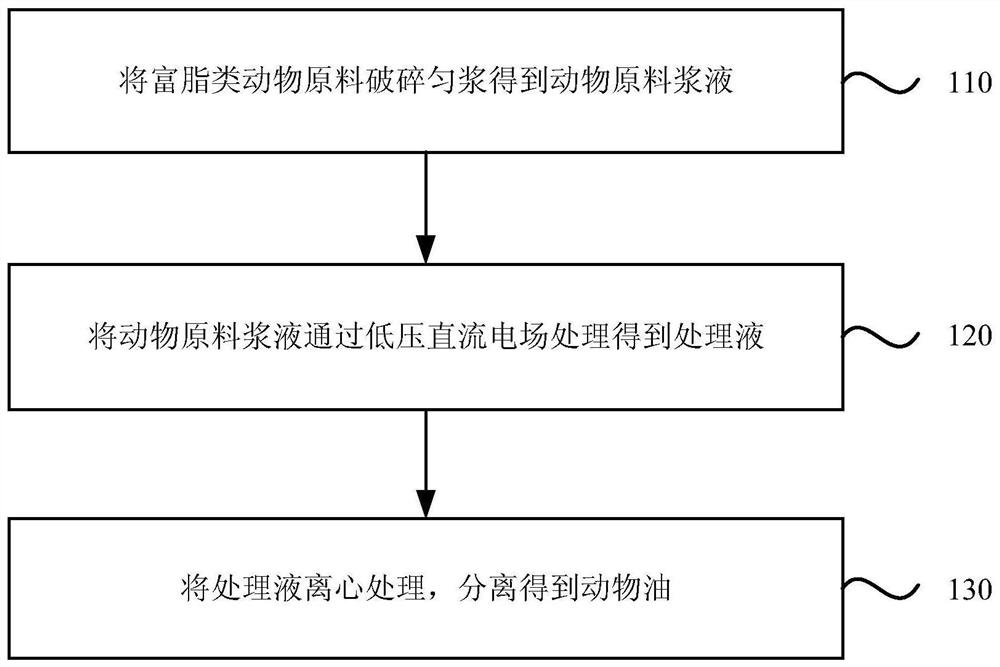

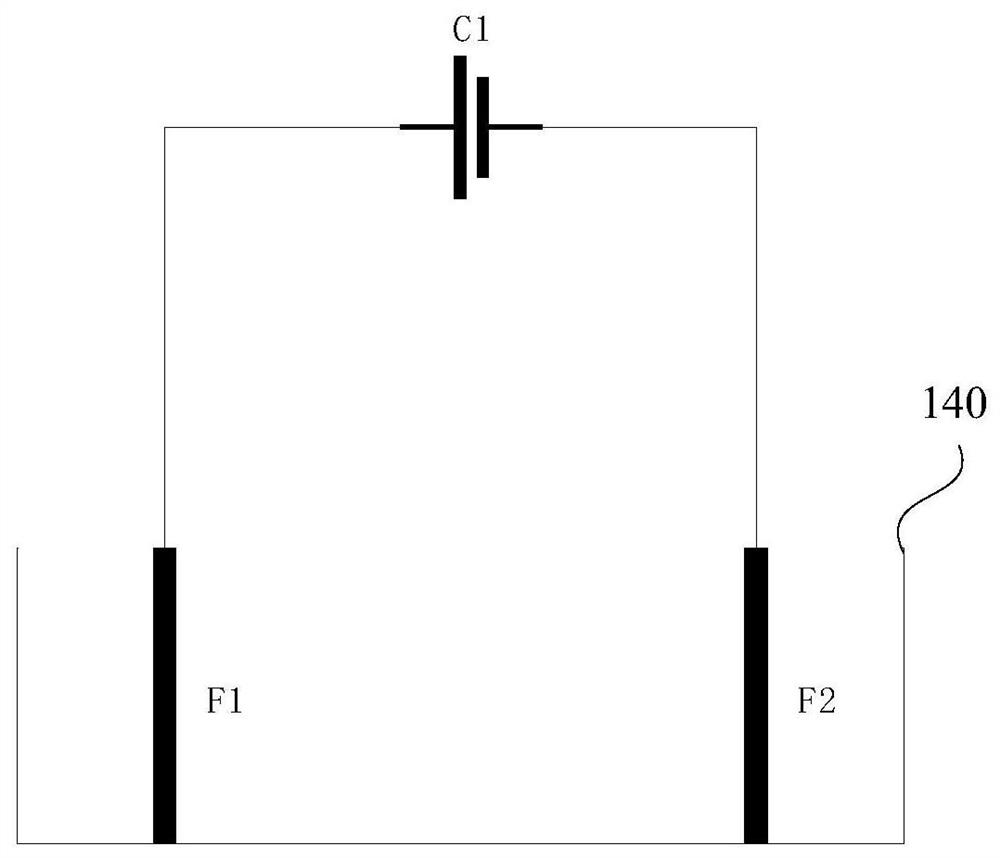

[0032] figure 1 It is a flow chart of an animal oil extraction method provided in Embodiment 1 of the present invention. This embodiment is applicable to oil extraction. The method can be performed by an animal oil extraction device, and specifically includes the following steps:

[0033] Step 110, crushing and homogenizing fat-rich animal raw materials to obtain animal raw material slurry.

[0034] Among them, fat-rich animal raw materials refer to animal raw materials rich in fat, such as fatty pork, fatty beef, fatty lamb, squid, abalone, and mackerel. Certainly not limited to the listed animal raw materials, other fat-rich animal raw materials can also be extracted using the method provided by the present invention.

[0035] Specifically, fresh fat-rich animal raw materials are washed, crushed and homogenized with a tissue masher to obtain animal raw material slurry. Animal raw material slurry is a very stable slurry material that is mixed with animal oil, protein and ot...

Embodiment 2

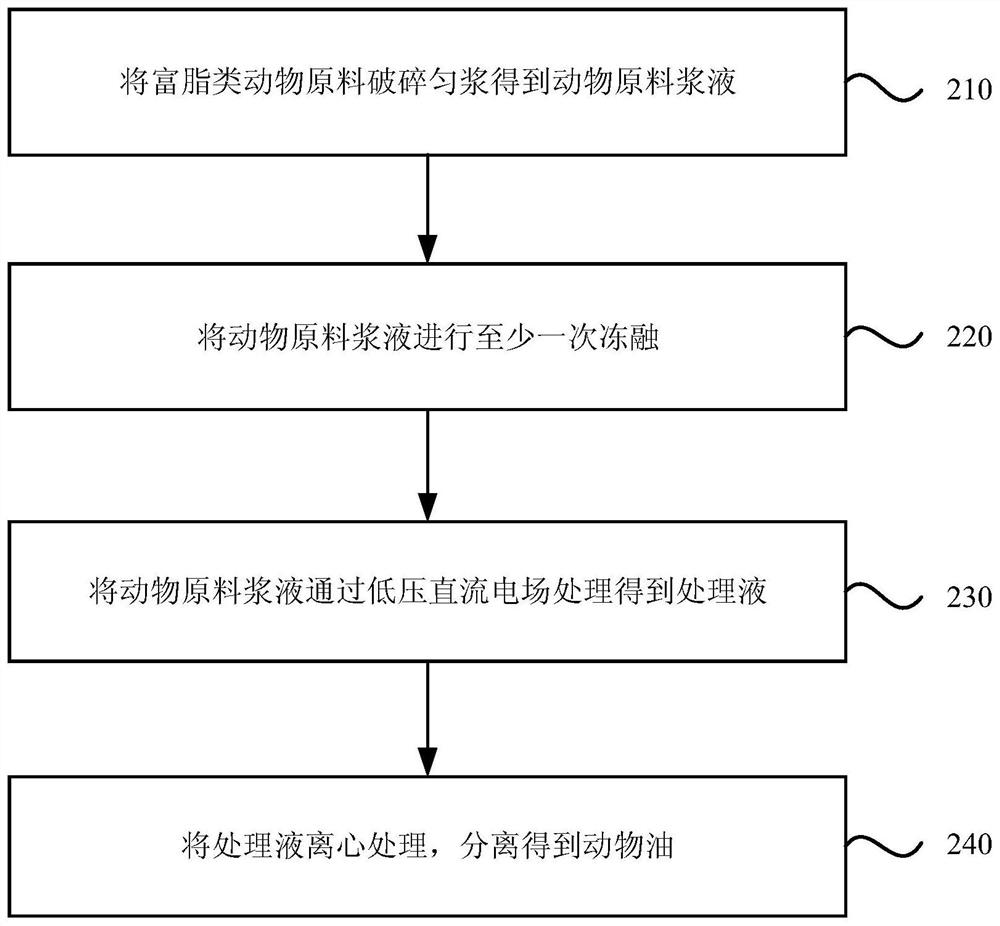

[0048] image 3 It is a flow chart of an animal oil extraction method provided in Embodiment 2 of the present invention. This embodiment is further refined on the basis of the above embodiments, and specifically includes the following steps:

[0049] Step 210, crushing and homogenizing fat-rich animal raw materials to obtain animal raw material slurry.

[0050] Step 220, freezing and thawing the animal raw material slurry at least once.

[0051] Among them, the animal raw material slurry is a very stable slurry material formed by mixing animal oil, protein and other components. Freeze-thawing is the process of freezing and then thawing. Repeated freezing and thawing before power-on is conducive to the increase of oil extraction rate.

[0052] Optionally, when the animal raw material slurry is frozen and thawed, the freezing temperature is -50 to -4°C, preferably -45 to -30°C.

[0053]Exemplarily, the animal raw material slurry obtained after crushing and homogenizing is di...

Embodiment 3

[0064] Figure 4 It is a flow chart of an animal oil extraction method provided by Embodiment 3 of the present invention. This embodiment is further refined on the basis of the above embodiments, and specifically includes the following steps:

[0065] Step 310, crushing and homogenizing fat-rich animal raw materials to obtain animal raw material slurry.

[0066] Optionally, the fat-rich animal raw material is a fat-rich aquatic animal raw material.

[0067] Optionally, the fat-rich aquatic animal raw material is fat-rich aquatic animal viscera or fat-rich aquatic animal meat.

[0068] Among them, fat-rich animal raw materials are mainly concentrated in animal viscera or animal meat, and some are concentrated in animal heads. If the fat-rich animal raw materials are fat-rich aquatic animal raw materials, such as squid and abalone, the main oil is distributed in the viscera, and the main oil of mackerel is distributed in the head.

[0069] Step 320, treating the animal raw ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com