Advanced treatment apparatus for printing and dyeing wastewater

A technology for advanced treatment of printing and dyeing wastewater, applied in textile industry wastewater treatment, neutralized water/sewage treatment, reduced water/sewage treatment, etc., can solve the problems of poor treatment efficiency and high cost, reduce the burden and improve biodegradability , Improve the effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

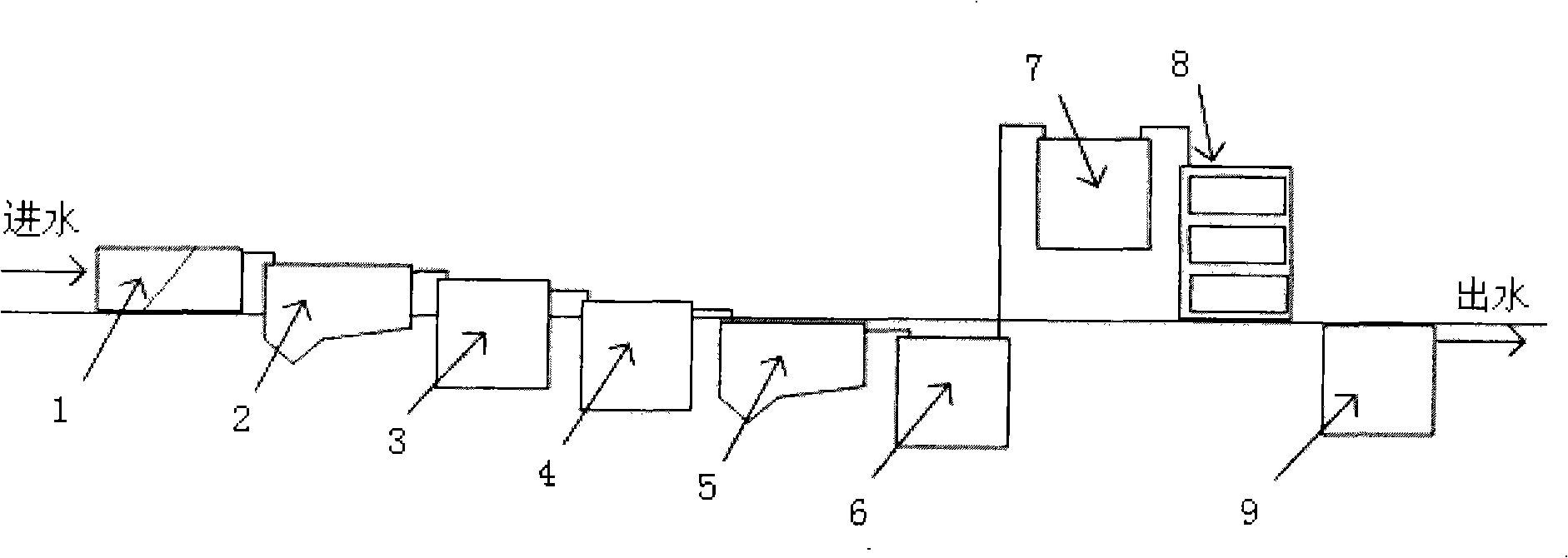

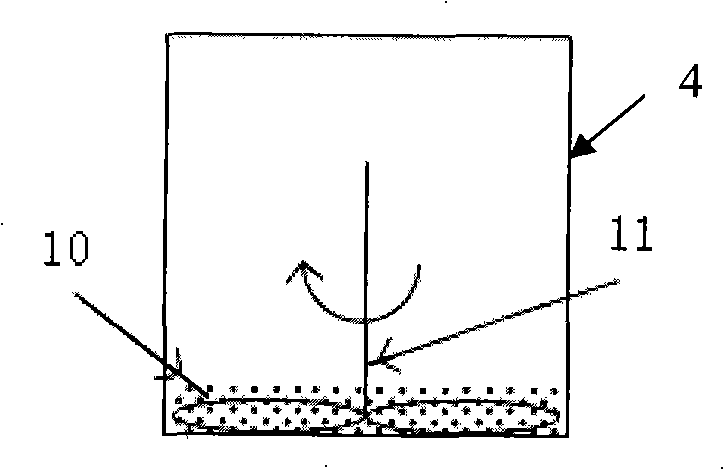

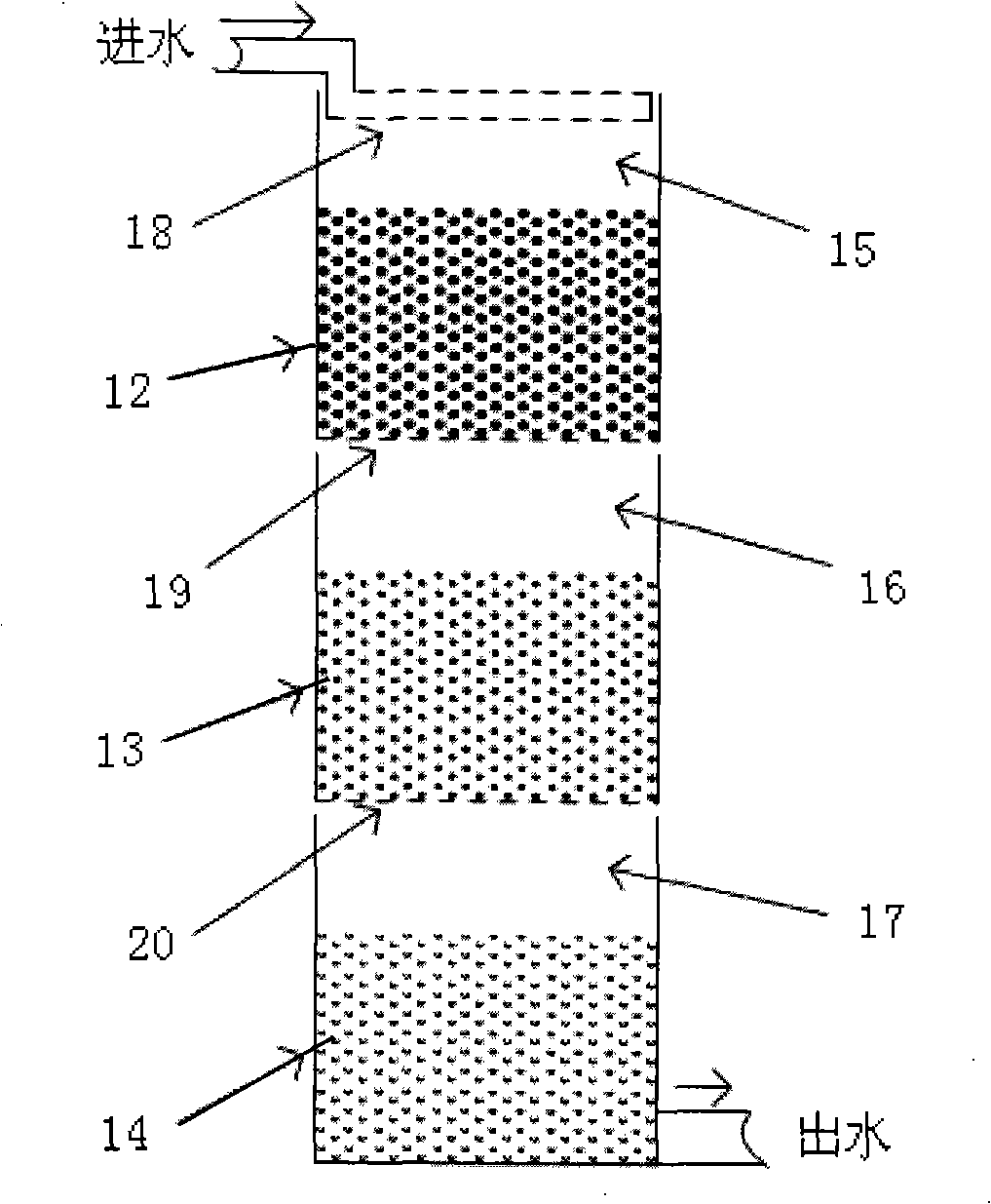

[0019] The processing device of the present invention is as figure 1 As shown, there are grid pool 1, pre-sedimentation pool 2, acid-base adjustment pool 3, decolorization reaction pool 4, sedimentation pool 5, neutralization pool 6, lifting distribution pool 7, biogeological combination filter pool 8 and secondary sedimentation pool 9 Composition, grid pool 1, pre-sedimentation tank 2, acid-base adjustment tank 3, sedimentation tank 5, neutralization tank 6, promotion water distribution tank 7 and secondary sedimentation tank 9 all can adopt prior art wherein, described decolorization reaction tank ( figure 2 ) is provided with an iron filings layer 10 and an agitator 11 with a thickness of 10-20 cm, and the maximum particle size of the iron filings used is no more than 5 mm. Printing and dyeing wastewater passes through grid pool 1 and pre-sedimentation tank 2 to remove suspended solids and large particles of impurities, adjust the pH to 5-6 in the acid-base adjustment tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com