A control method for correcting pmsm motor compensation items

A control method and project technology, applied in the direction of motor control, motor generator control, AC motor control, etc., can solve the problem of unavoidable compensation of errors, and achieve the effects of improving control accuracy, strong adaptability and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

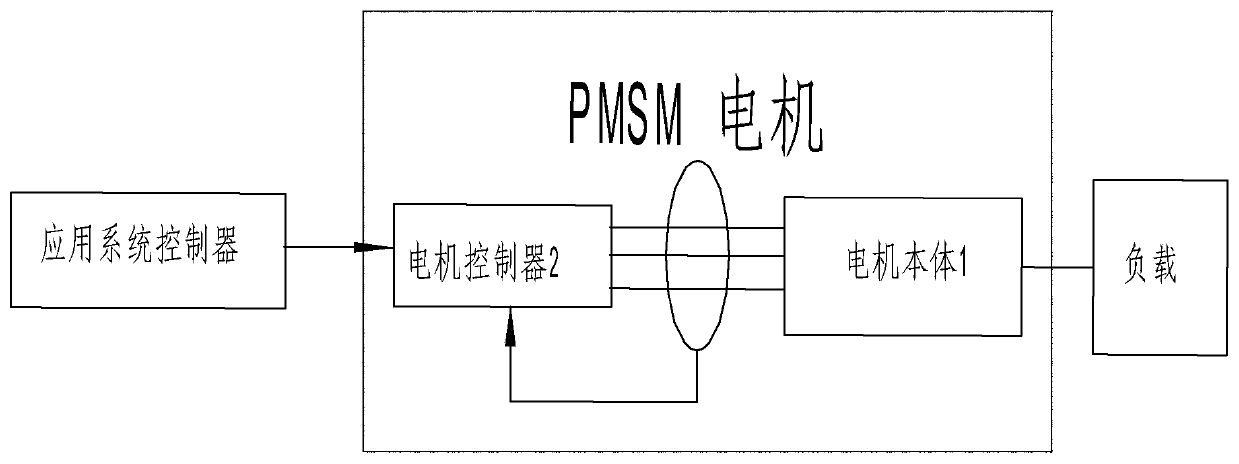

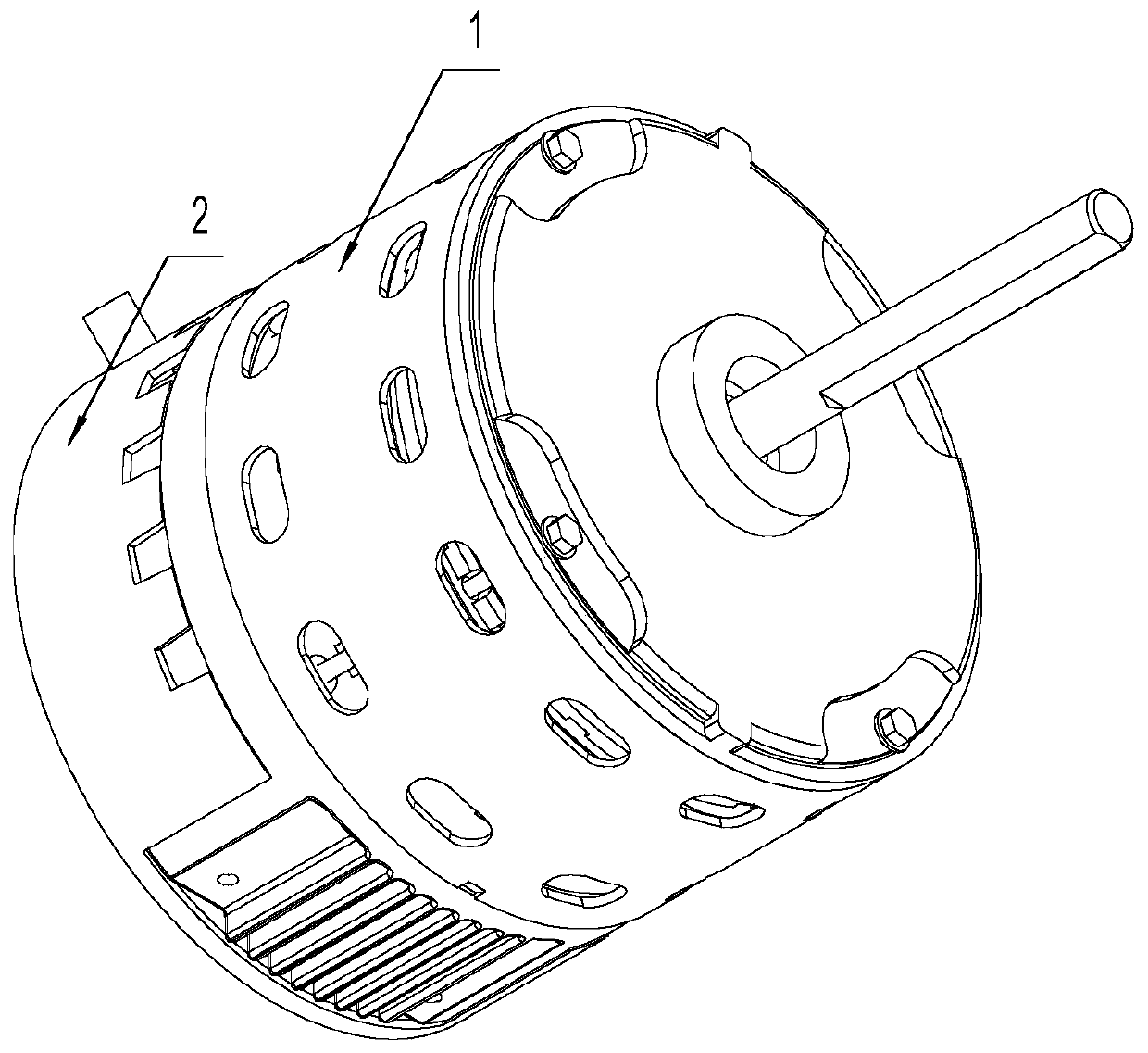

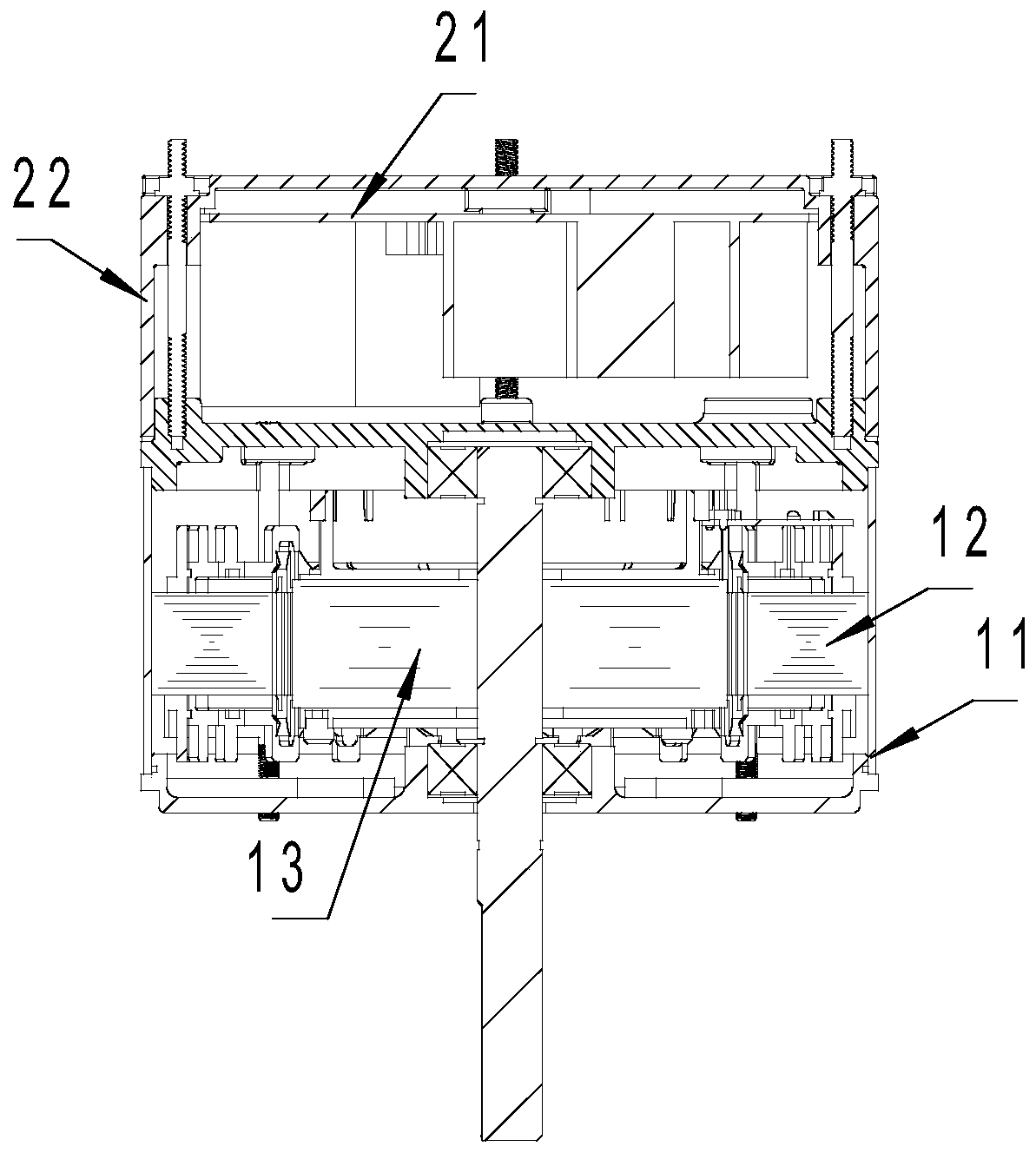

[0054] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the present invention mentions that the PMSM motor includes a motor controller 2 and a motor body 1, and the motor body 1 includes a stator assembly 12, a rotor assembly 13 and a casing assembly 11, and the stator assembly 13 is installed on the casing assembly 11 The motor unit 1 is equipped with a Hall sensor for detecting the position of the rotor or adopts the method of detecting the phase current. The rotor assembly 13 is set on the inside or outside of the stator assembly 12. The motor controller 2 includes a control box 22 and is installed in the control box 22. Inside the control circuit board 21, the control circuit board 21 generally includes a power supply circuit, a microprocessor, a bus current detection circuit and a frequency converter. The on and off of the coil windings of each phase.

[0055] Figure 5 The inverter in the inverter can be an integrated power module (IPM) or ...

example 3

[0095] Motor 4 is designed as a 1-horsepower motor, and the motor parameters are measured: stator resistance = 1.65Ω, d-axis inductance = 26mH, q-axis inductance = 42mH, λm = 0.1582Vs, using frequency converter A, with 650ns (nanosecond) required dead time. The dead-time look-up table calculation uses the same motor production run as the inverter, but uses a calculated worst-case dead time of 1500ns. Using the same motor product (motor 4) and frequency converter A, we measure and calculate the dead zone compensation lookup table, the calculated dead zone compensation of the limit is 1500ns, and frequency converter A acts on the stator coil winding under a motor command DC voltage , the current of the stator coil winding is measured, and the measured voltage is calculated and compared with the command DC voltage to obtain the dead zone compensation value (dead zone error), according to Figure 11 The steps obtained using motor 4 and the same frequency converter A, Edt is calcu...

Embodiment 2

[0112] The present invention is a control method for correcting PMSM motor compensation items, which is characterized in that: by off-line measurement of the data of motor control errors caused by a certain parameter of the motor, and obtaining the current command and the look-up table of the compensation items based on the above-mentioned certain parameters And store it in the memory of the motor controller; start the motor to make the motor operate normally, and when the motor is running online, use the look-up table of the compensation item of a certain parameter above to correct the compensation item again to adapt to the current working condition of the motor. The purpose of precise control.

[0113] The parameter of the motor measured offline is the stator resistance, and the obtained look-up table is a look-up table corresponding to the stator resistance and the ambient temperature.

[0114] Then establish an equation λ=f(U, I, R, L, Edt, Vdt, λm) according to the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com