Receipt printing machine

A technology for printing presses and bills, applied in printing presses, rotary printing machines, printing and other directions, can solve the problems of inability to locate, reduce the processing quality and processing accuracy of invoices, etc., to avoid interference, accurately and effectively punch holes, and reduce speed. poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Further detailed explanation through specific implementation mode below:

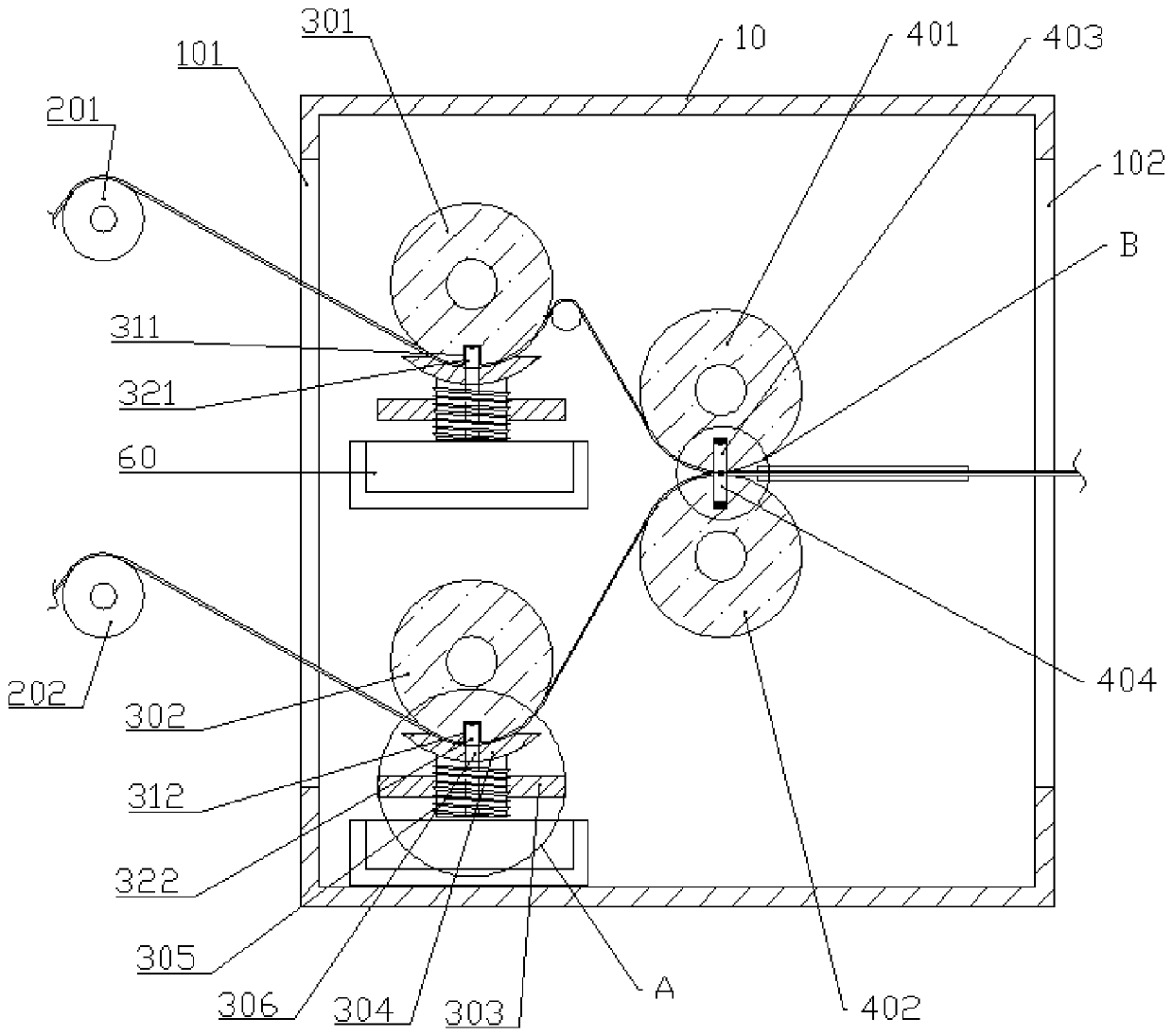

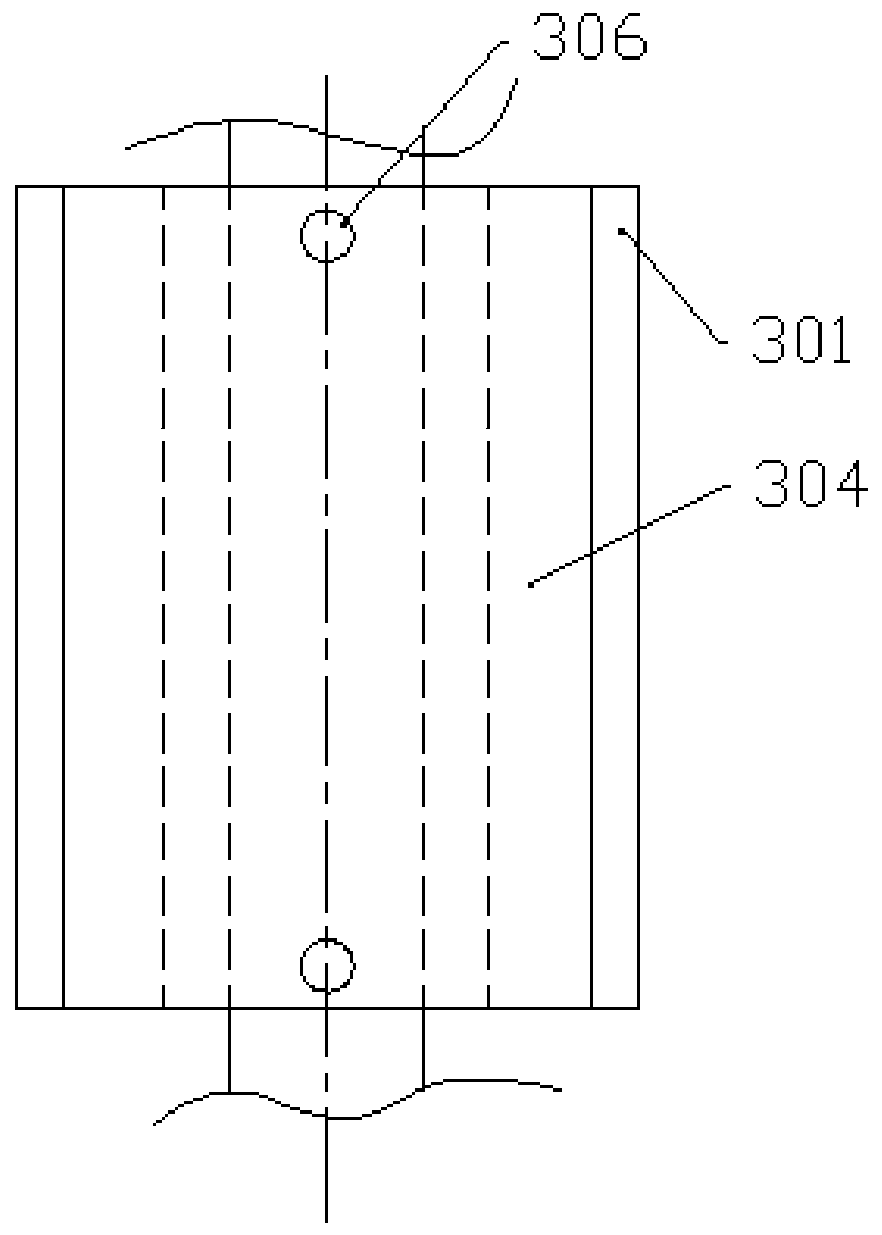

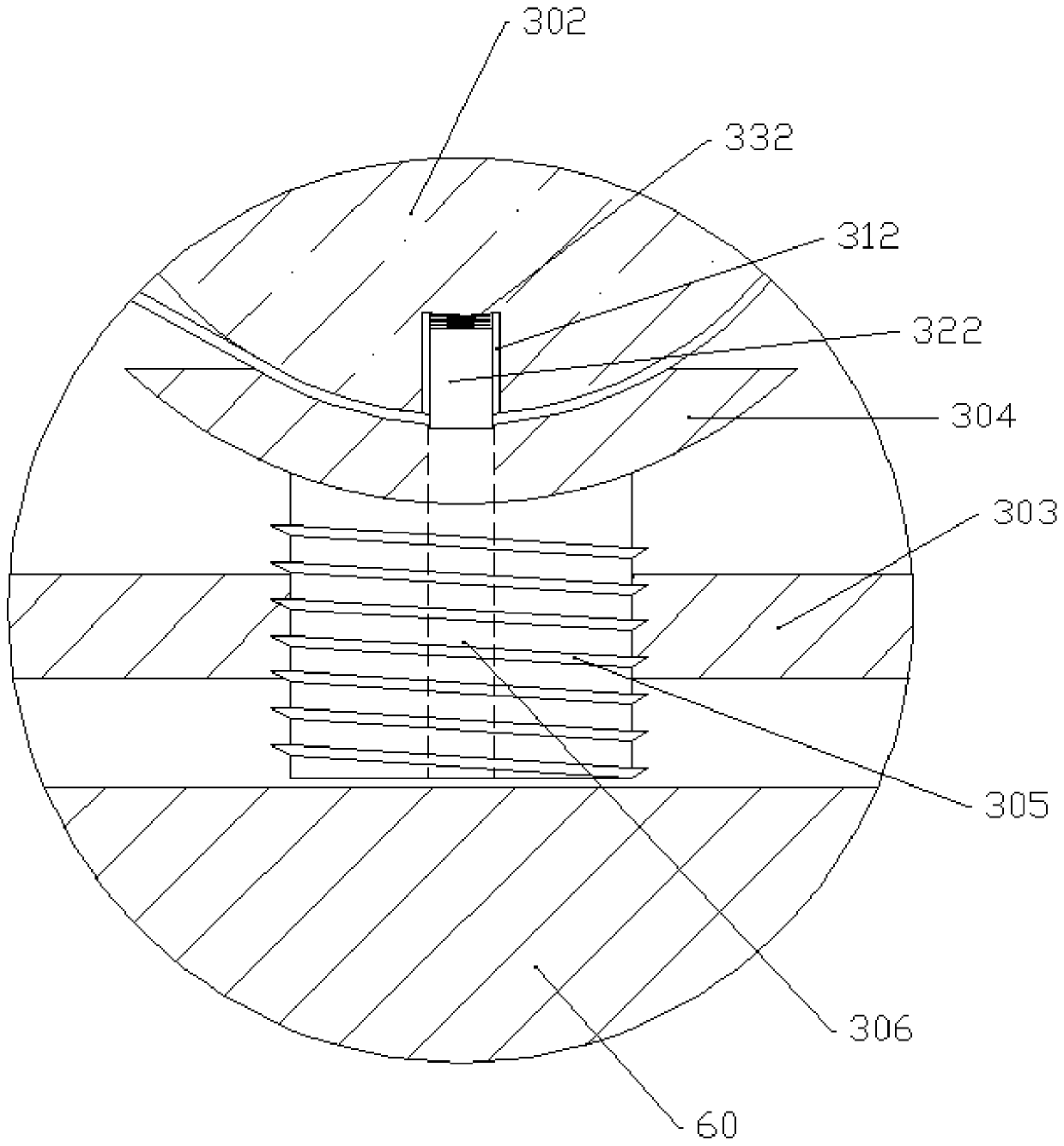

[0022] The reference signs in the accompanying drawings of the specification include: casing 10, inlet 101, outlet 102, first transmission wheel 201, second transmission wheel 202, first printing roller 301, first mounting hole 311, first punching knife 321 , the second printing roller 302, the second mounting hole 312, the second punching knife 322, the second tension spring 332, the fixing plate 303, the supporting plate 304, the adjusting rod 305, the through hole 306, the first conveying roller 401, the second Transmission roller 402, first push rod 403, second push rod 404, first connecting block 405, second connecting block 406, first pressing spring 407, second pressing spring 408, first pressing plate 501, second pressing Tightening plate 502 , glue outlet plate 503 , glue outlet 504 , collection frame 60 .

[0023] The embodiment is basically as attached figure 1 , attached figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com